Square billet continuous casting starting method

A billet and continuous casting technology, applied in the field of steel manufacturing, can solve problems such as difficulty in ingot pulling, increase production cost and labor intensity, and break out steel, so as to save preparation time, prevent cold material from falling into the gap, and simplify operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Below in conjunction with accompanying drawing, this method embodiment is described in further detail:

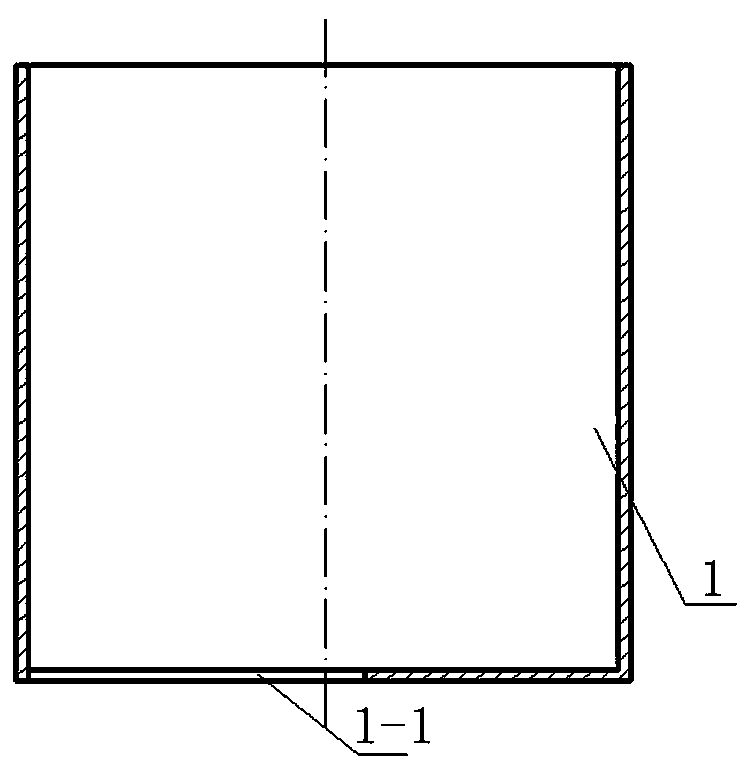

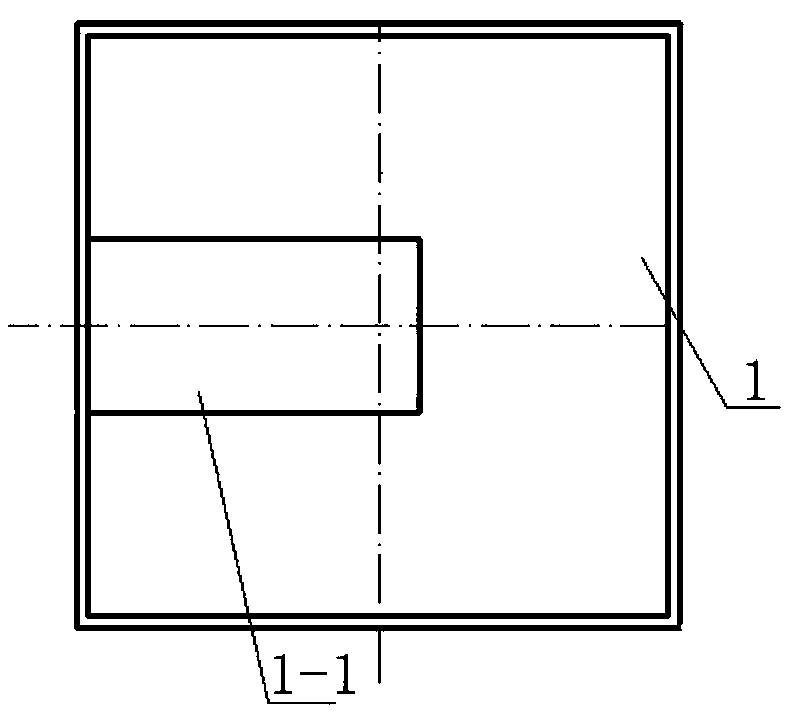

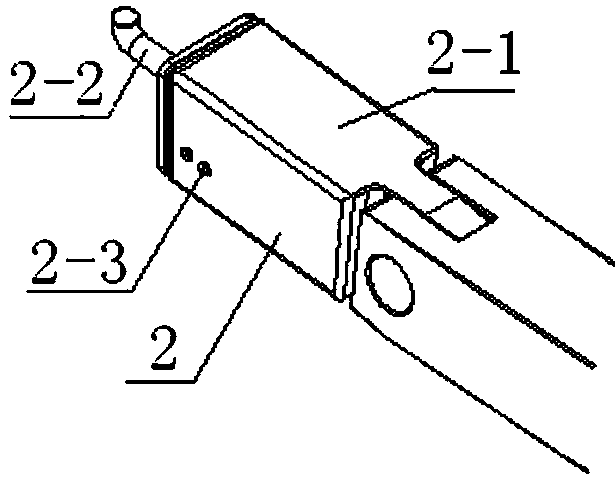

[0026] The starting method of continuous casting of square billets is taken as an example of HRB400E series steel grades planned to be produced by a 7-strand billet continuous casting machine with a cross-section of 165mm×165mm: when preparing for production, after each flow is filled with dummy ingots, cover the crystallizer with asbestos cloth Put the cold material iron cylinder 1 on the dummy rod 2-1 of the dummy head 2 in the crystallizer, and use the feeding funnel to distribute the cooling material into the quantitative material iron cylinder 3 to ensure that the tundish is opened After pouring, the pouring flow is quickly welded with the cold material iron cylinder in the mold to form a primary billet shell. After starting, the dummy rod hinged on the dummy rod pulls the billet out of the mold along the copper tube.

[0027] The cold material iron cylinder 1, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com