Surface rough grinding device for gear processing

A gear and coarse grinding technology, which is applied in gear tooth manufacturing devices, metal processing equipment, belts/chains/gears, etc., can solve the problems of low grinding efficiency and affecting processing speed, so as to improve service life, save resources and avoid side effects. Partial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

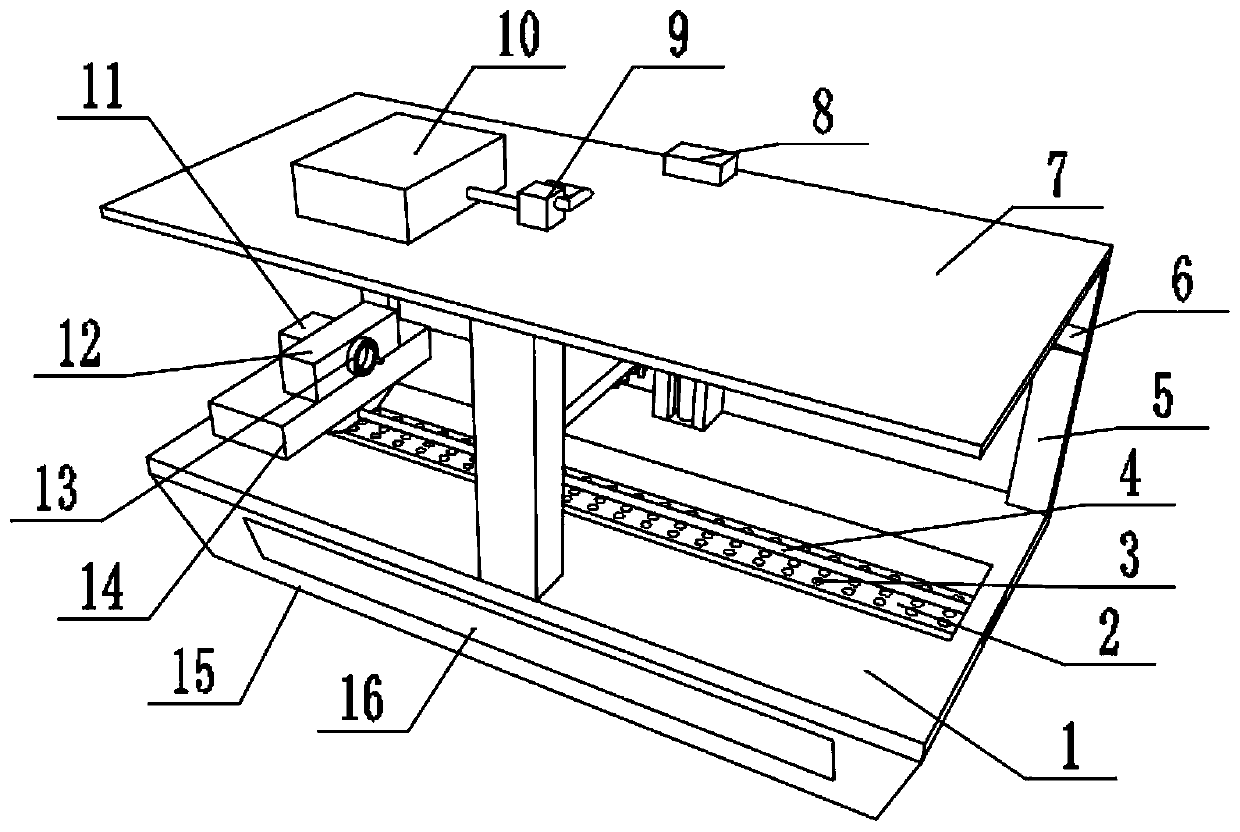

[0028] refer to Figure 1-3 , a surface rough grinding device for gear processing, comprising a workbench 1, columns 5 are welded on both sides of the top of the workbench 1, and the top outer walls of the two columns 5 are welded with the same top seat 7, the top Both sides of the bottom of the seat 7 are provided with a rough sharpening mechanism, and the top of the top seat 7 is provided with a cooling mechanism; the top of the workbench 1 has a groove 2, and a No. 1 screw 4 is fixed in the groove through a bearing. The outer wall of the No. 1 leading screw 4 is threadedly connected with a sliding seat 14, and the top of the sliding seat 14 is provided with a gear workpiece clamping mechanism.

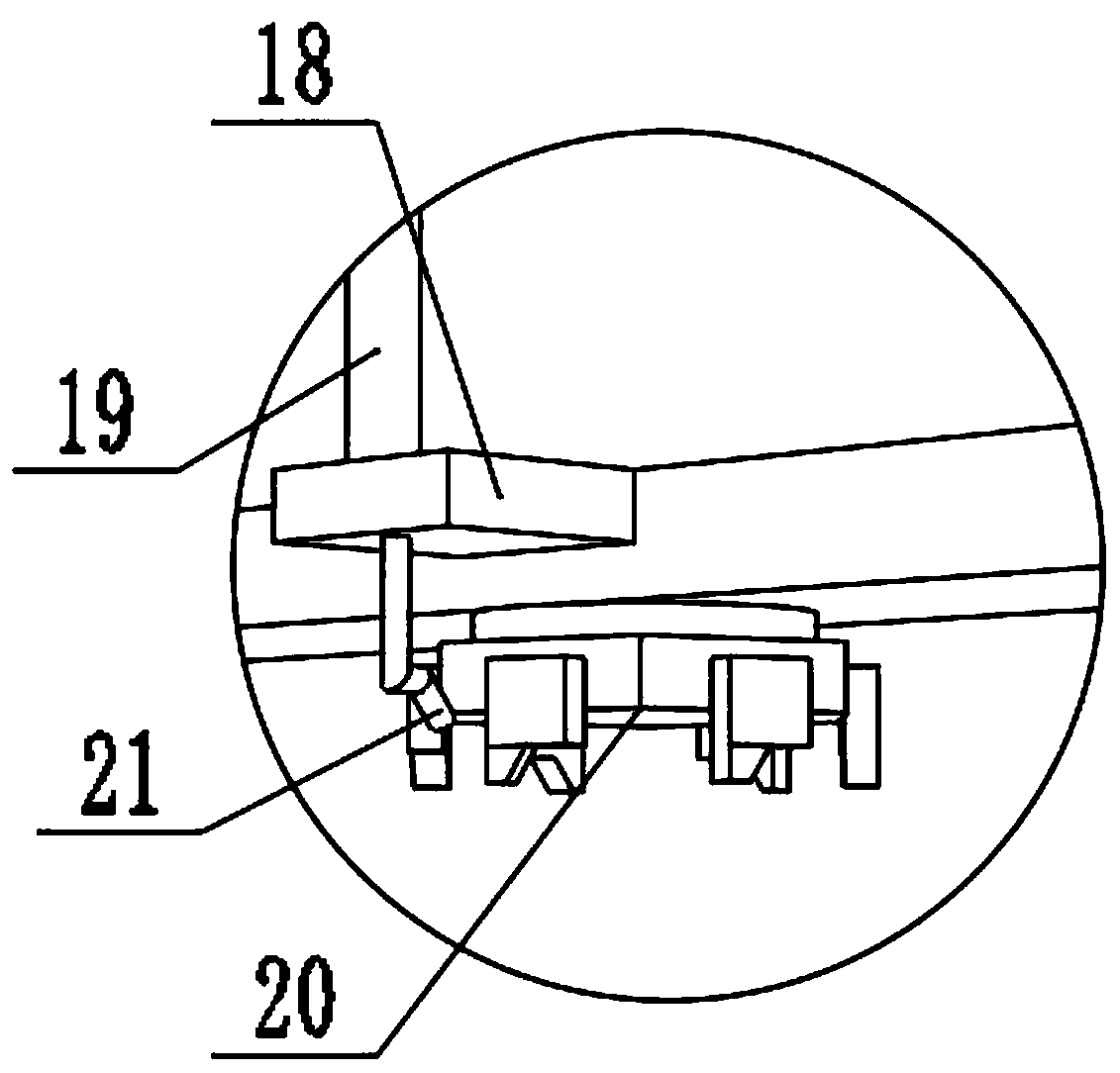

[0029] Wherein, the rough sharpening mechanism includes a fixed frame welded on both sides of the bottom end of the top base 7, and a No. 2 lead screw is fixed by a bearing in the fixed frame, and a No. 1 motor 8 is fixed on one side of the top base 7 by screws. The output shaft of...

Embodiment 2

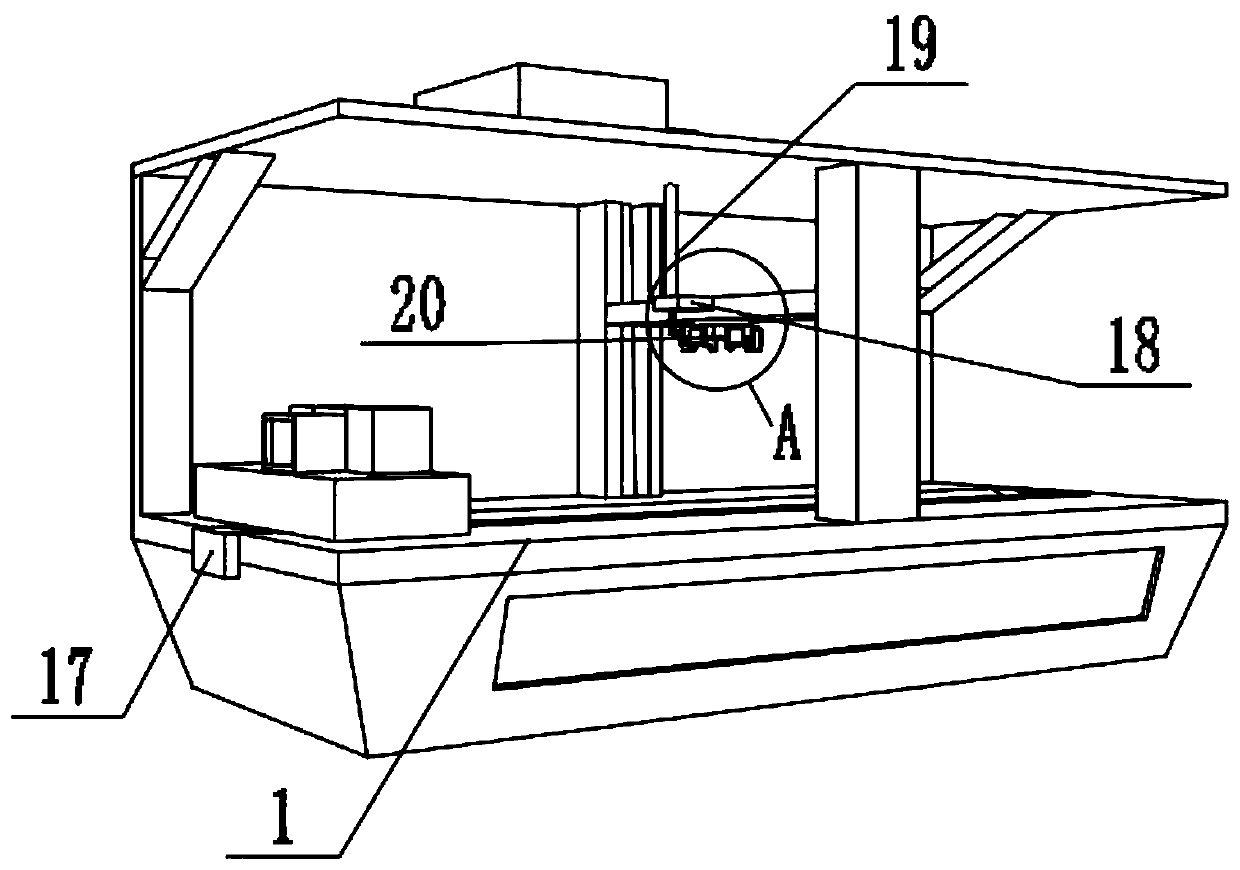

[0035] refer to image 3 , a surface rough grinding device for gear processing. In order to improve the energy-saving and environmental protection effect of the equipment, this embodiment makes the following improvements on the basis of embodiment 1: the inner walls on both sides of the groove 2 are inclined inward, and the groove There are several through-holes 3 in 2; the bottom of the workbench 1 is welded with a bottom box 15, and the side wall of the bottom box 15 is provided with a side cover 16; the cooling liquid sprayed by the nozzle 21 can flow into the In the bottom box 15, the coolant can be recovered, which is energy-saving and environment-friendly.

[0036] The working principle of this embodiment: during rough grinding, the nozzle 21 sprays coolant into the groove 2, and the inclined inner wall guides the liquid into the through hole 3, and flows into the bottom box 15 for recycling.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com