Sliding plate mooring rope quick loosening and anchor clamping tool

A loosening and fast technology, applied in the direction of transportation and packaging, ships, berths, etc., can solve the problems of hull paint or structural damage, long time for cutting off lifting lugs, and mutual collision of slide plates, so as to reduce the time for loosening cables and save Manpower, fixed and firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

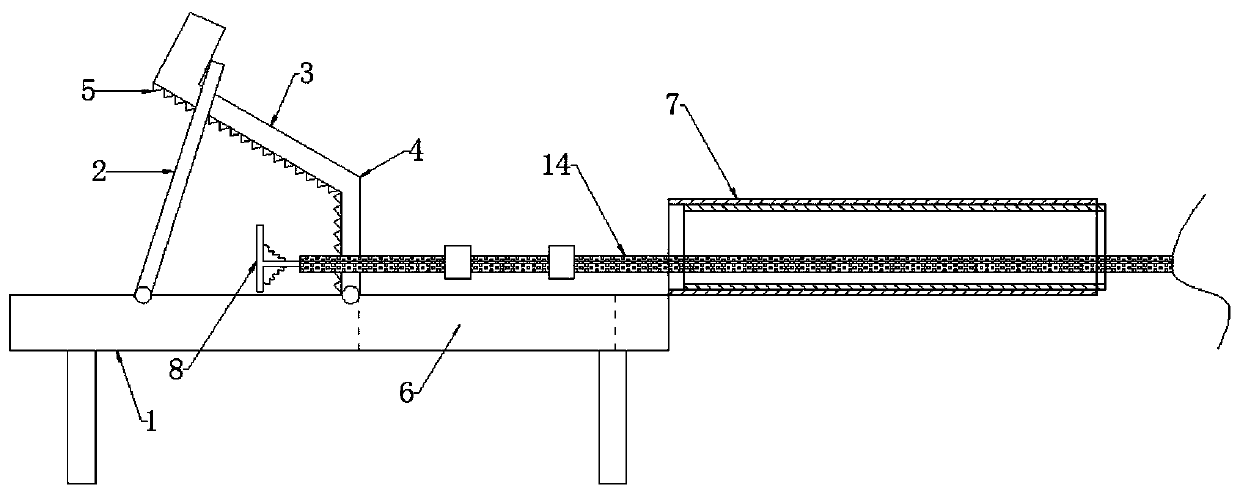

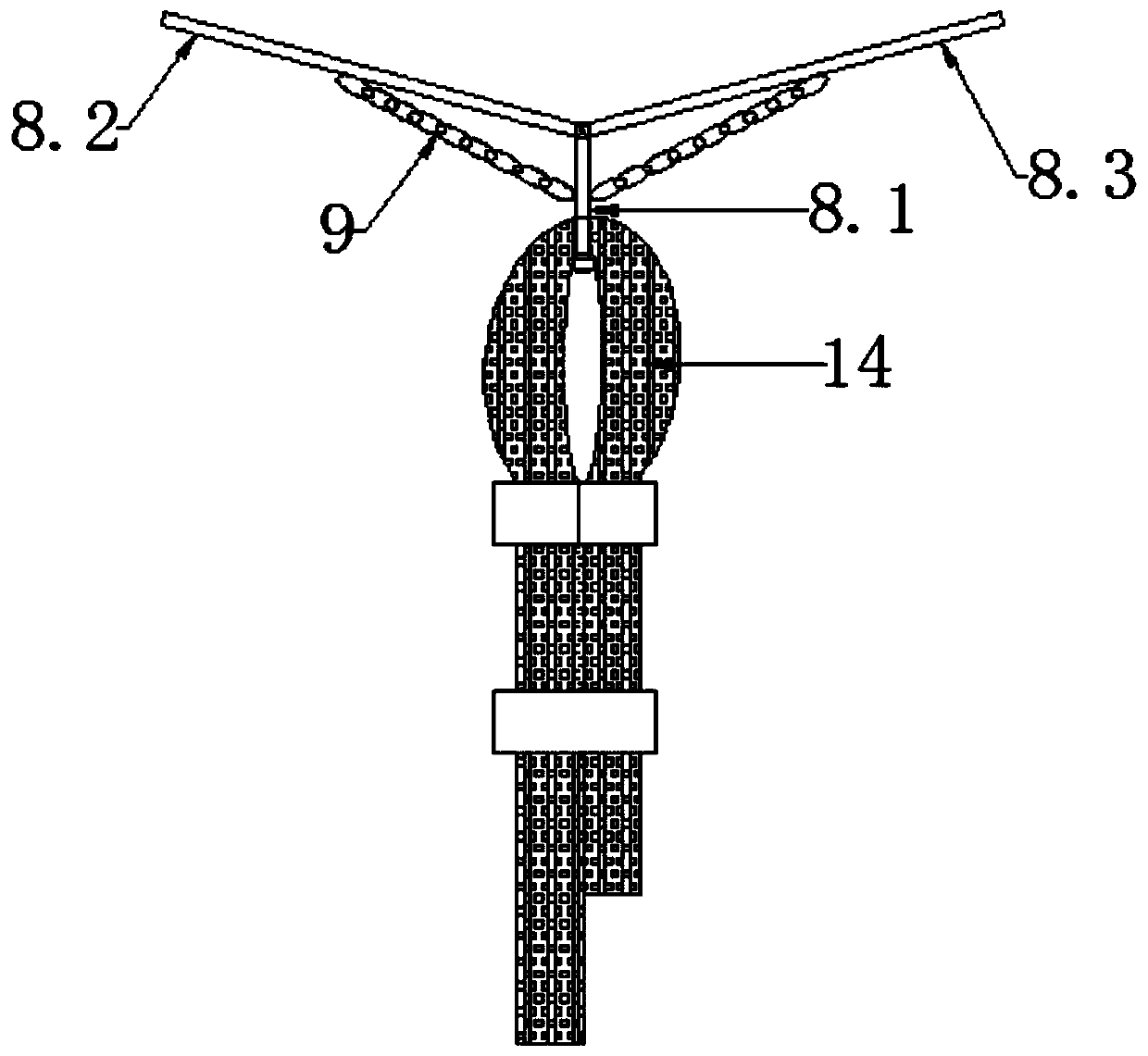

[0020] Such as figure 1 , 2 As shown, the present invention is a kind of skateboard retaining rope fast release anchor tooling, comprising a fixed frame 1, a buckle 2 arranged on the fixed frame and a flap 3 for fixing the cable 14, one end of the flap is connected to the The fixing frame is hinged, and the other end of the flap passes through the buckle, and the buckle is hinged with the fixing frame.

[0021] The distance between the connection point between the flap and the fixing frame and the buckle is less than the length of the flap.

[0022] The flap has a bending angle 4 facing the buckle, and an anti-skid rib 5 is provided on the inner side of the bending angle facing the connection point. Long through hole 6 can also be set on the plane of fixed mount, is convenient to have the turnover plate turnover of bending angle, and cable is loosened.

[0023] The tooling also includes a sleeve 7 for passing cables, the sleeve is formed by nesting pipes with successively s...

Embodiment 2

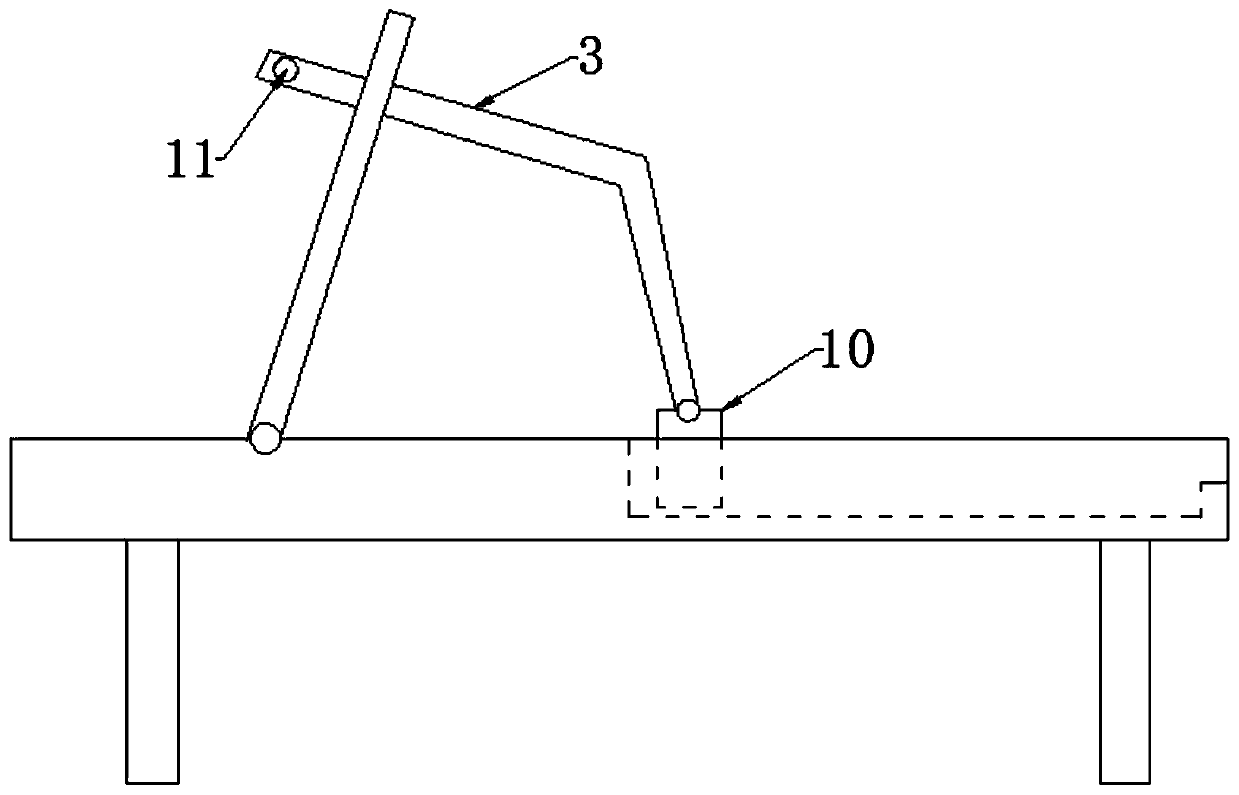

[0026] Such as image 3 As shown, the difference between Embodiment 2 and Embodiment 1 is that the flap 3 is hinged to the slider 10 arranged on the fixed frame, and the slider and the fixed frame are slidably connected along the loosening direction of the cable. A pin hole 11 is provided at one end of the flip plate and the buckle ring, and a pin shaft for fixing the flip plate and the buckle ring is pierced in the pin hole.

Embodiment 3

[0028] Such as Figure 4 As shown, the difference between embodiment 3 and embodiment 2 is that the slider 10 is slidably connected with the fixing frame along the loosening direction of the cable, and the side of the buckle away from the flap is also provided with a coplanar A fixed rod 12, the end of the flap is fastened with the fixed rod through a clamp 13.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com