Connecting structural component

A connection structure and integrated technology, applied in the direction of structural elements, building components, building reinforcements, etc., can solve problems affecting connection strength and connection stability, so as to ensure connection strength and reliability, improve connection strength, and avoid axial The effect of displacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further elaborated below with examples in conjunction with the accompanying drawings.

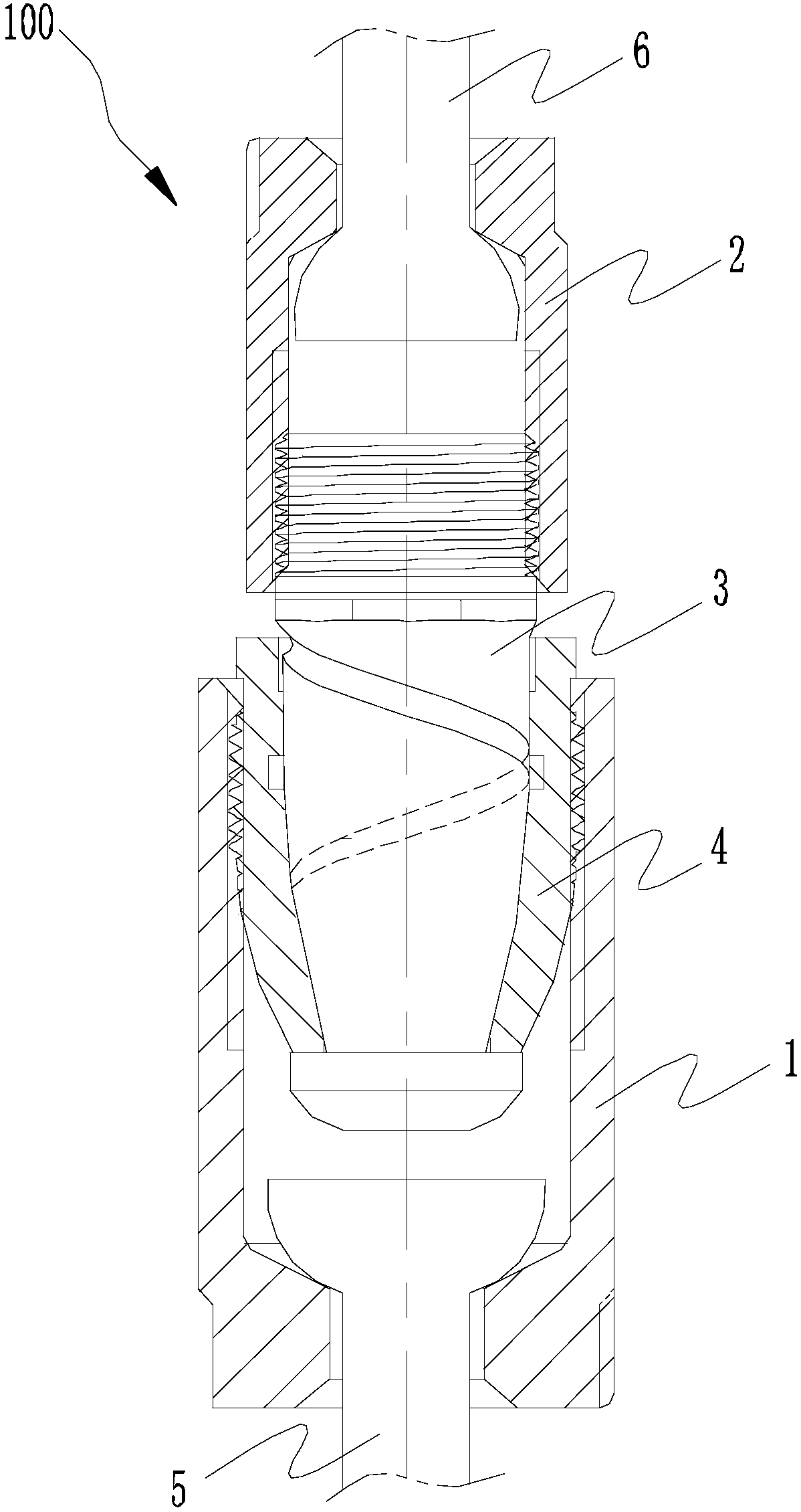

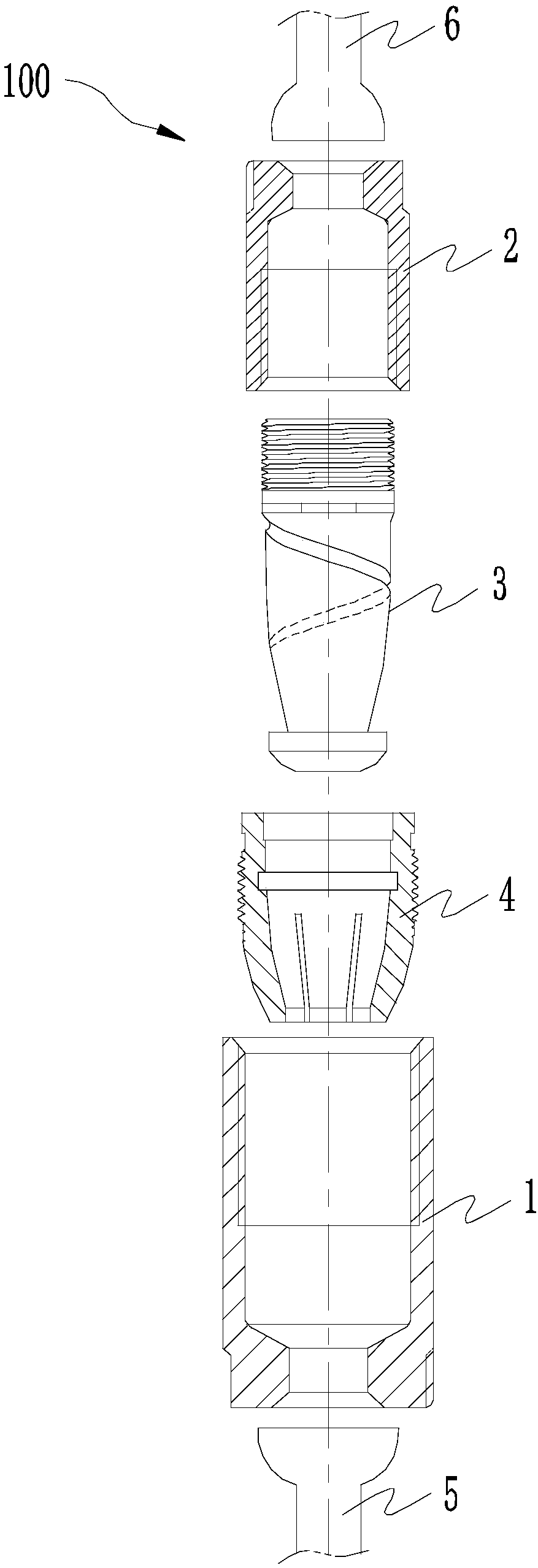

[0052] Such as figure 1 with figure 2 As shown, the present embodiment provides a connecting structure 100, which is used to connect two prefabricated building structures (such as between piles, between walls, between piles and columns) , or between the wall and the floor, etc.) in which the axes are aligned with each other or as far as possible (such as steel bars, steel rods, or any strip that meets the rigidity and strength requirements). Specifically, the connection structure 100 includes: a first rotary joint 1 , a second rotary joint 2 , an insertion rod 3 and a collet 4 .

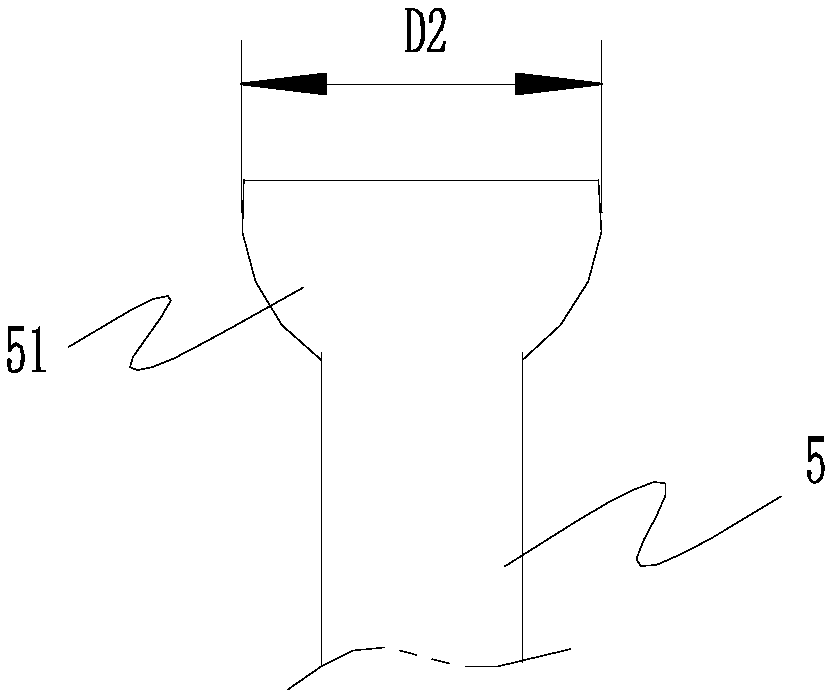

[0053] Such as figure 1 , image 3 as well as Figure 4 As shown, in this embodiment, the first rigid bar 5 is embedded in the first prefabrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com