Debugging method for improving failure working mode consistency of triplex-redundancy servo valves

A technology of working mode and debugging method, which is applied in the testing of fluid pressure actuating system, fluid pressure actuating device, mechanical equipment, etc., can solve the problems of once-faulted work performance decline, inconvenient debugging of servo system, and lack of in-depth research, etc. Improve debugging efficiency, facilitate parameter setting, and improve the effect of flow curve linearity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The technical solutions of the present invention will be clearly and completely described below in conjunction with the drawings and specific implementation methods of the present invention.

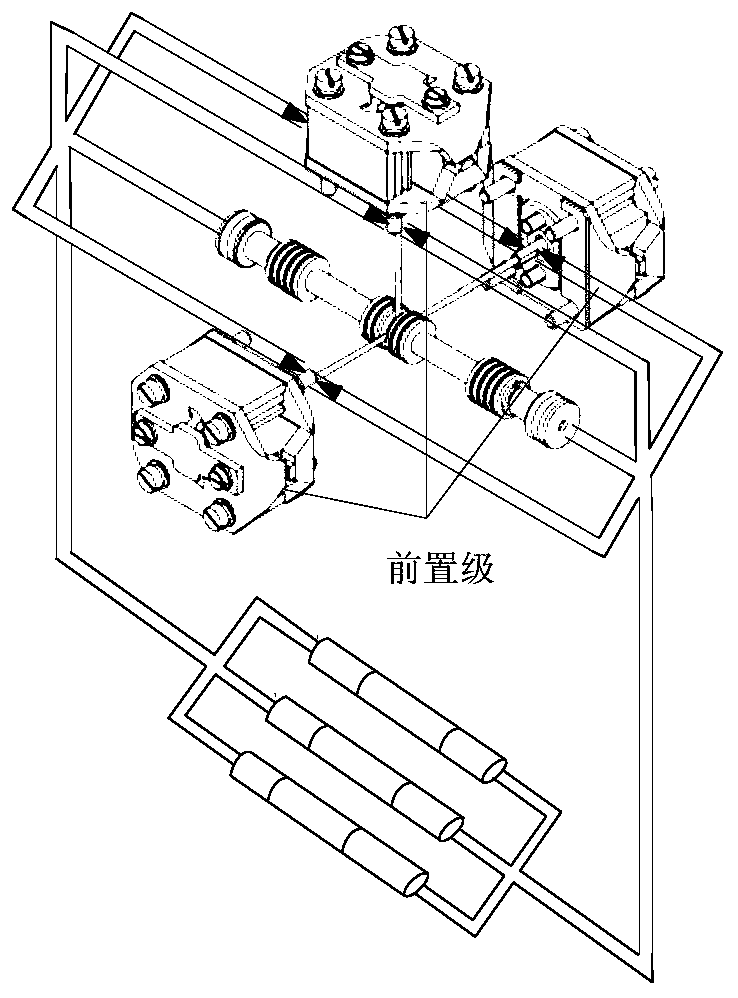

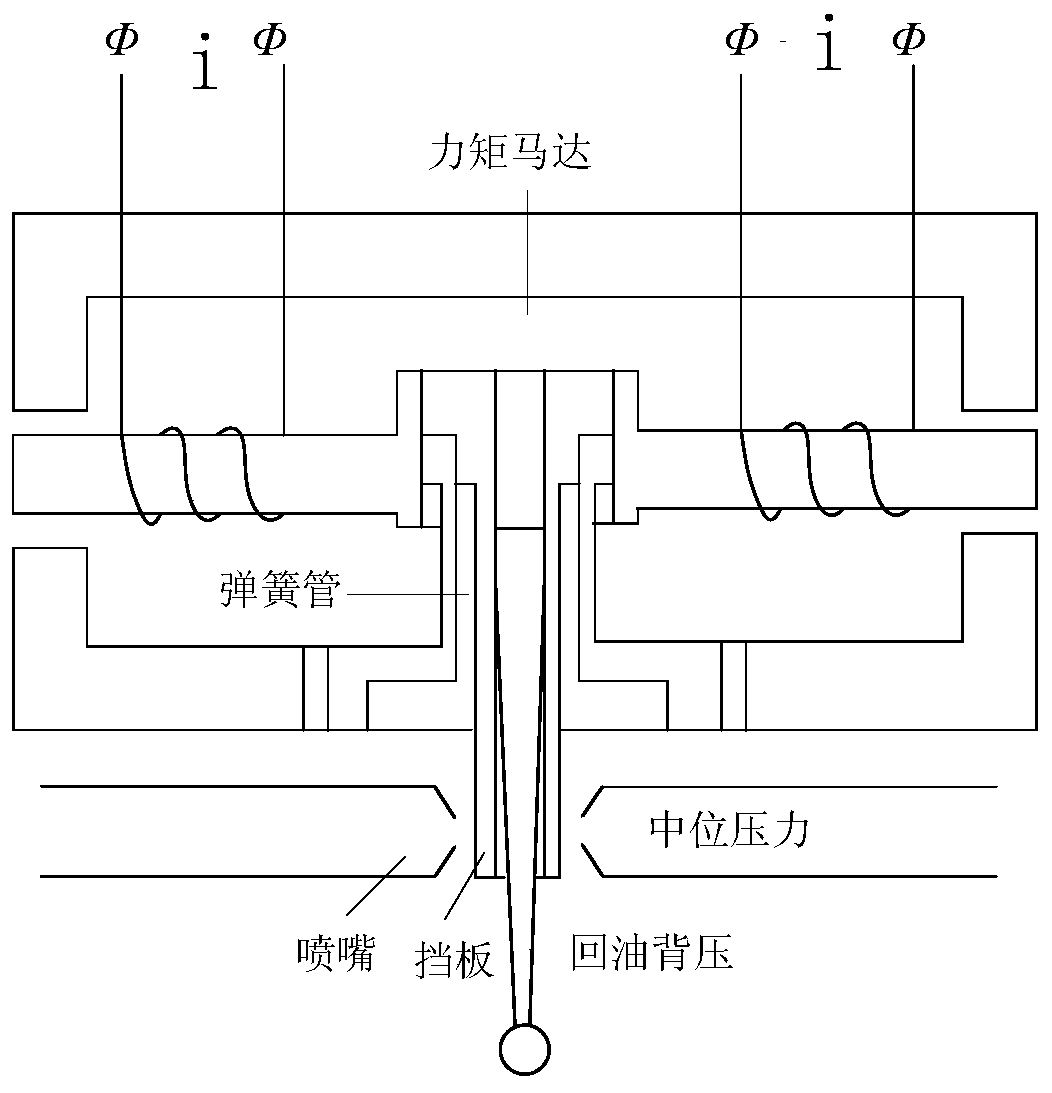

[0035] Such as figure 1 Shown is the schematic diagram of the structure of the three-redundancy servo valve, such as figure 2 Shown is the schematic diagram of the servo valve pre-stage structure.

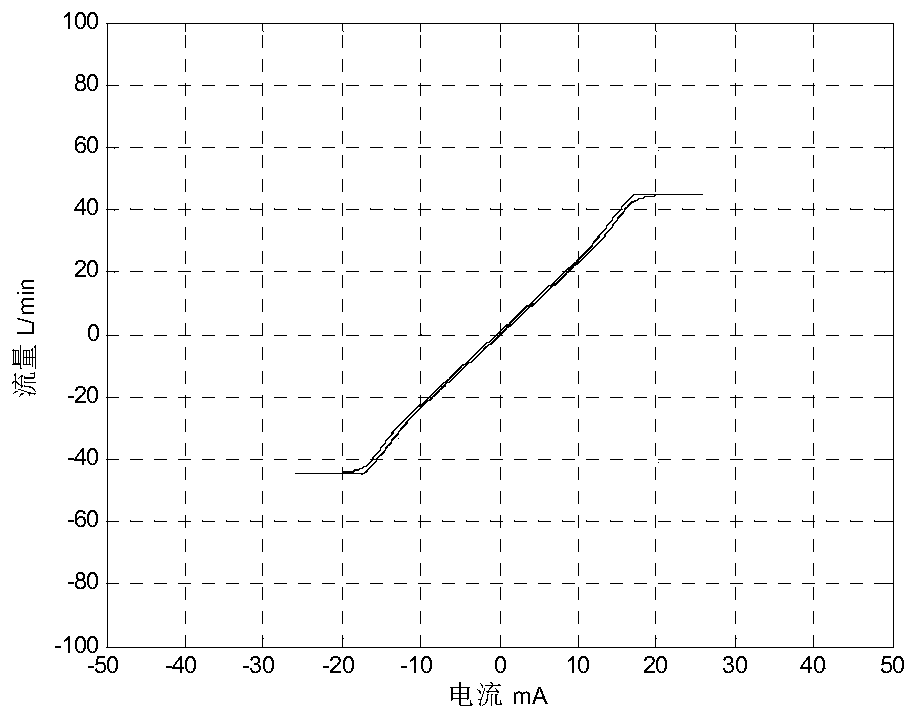

[0036] 1. When the fault flow curve of the redundant servo valve is saturated once, the saturated flow rate is significantly reduced, even lower than two-thirds of the normal working state, and the rated saturated flow rate is set to 84L / min, such as image 3 As shown, the saturated flow rate is reduced to 45L / min. At this point, perform debugging to increase the saturation flow in the fault state.

[0037] Debugging step 1: Improve the jet shape of the nozzle hole, screen out nozzles that do not scatter and concentrate the jet, and avoid self-excitation when the median pressure is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com