Drainage device for repairing fuel gas pipeline

A technology for gas pipelines and water inlet pipelines, which is applied to the components, pump devices, pipe elements and other directions of pumping devices for elastic fluids, can solve problems such as inconvenient operation, achieve good emergency repair effect, and reduce the probability of slipping , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

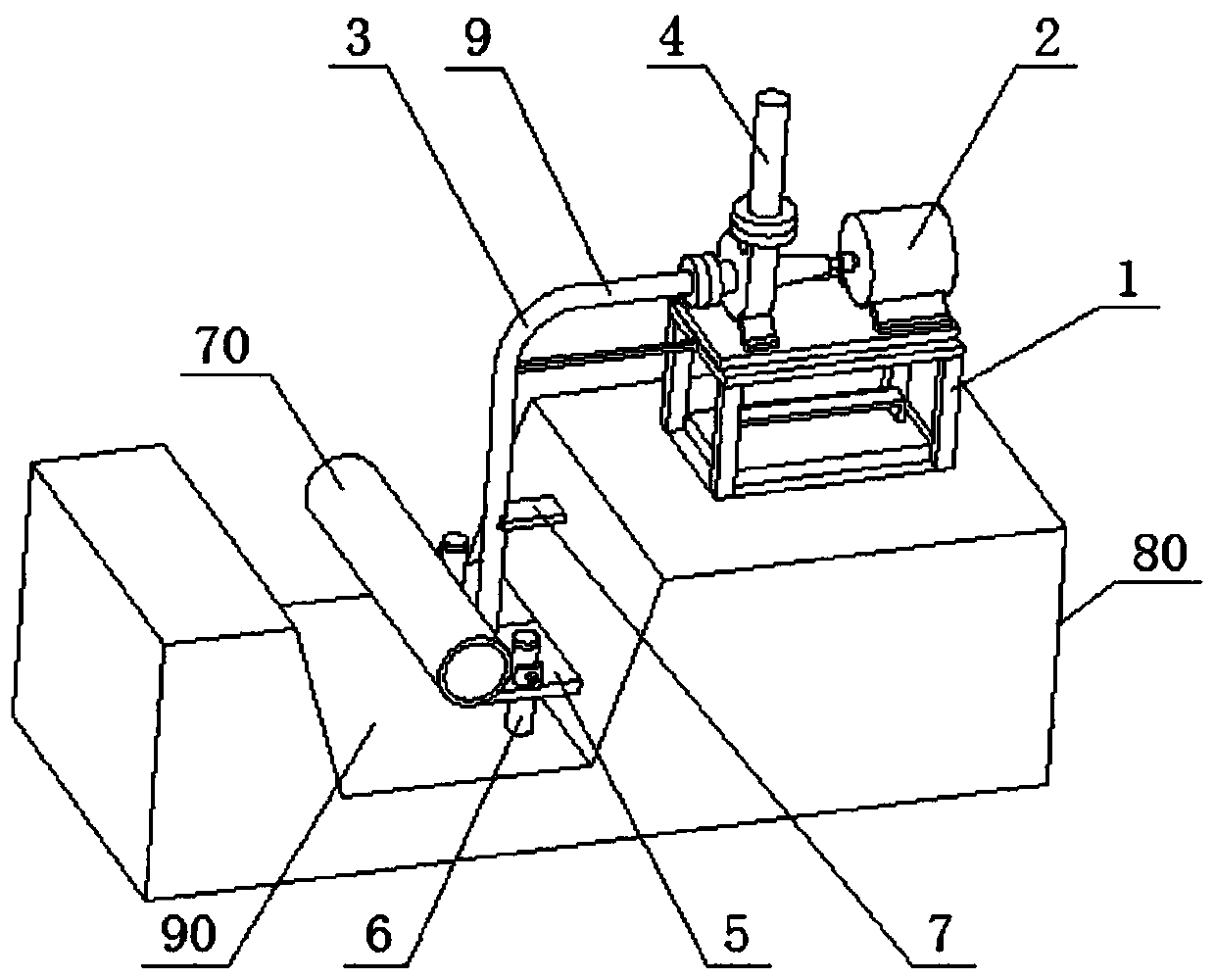

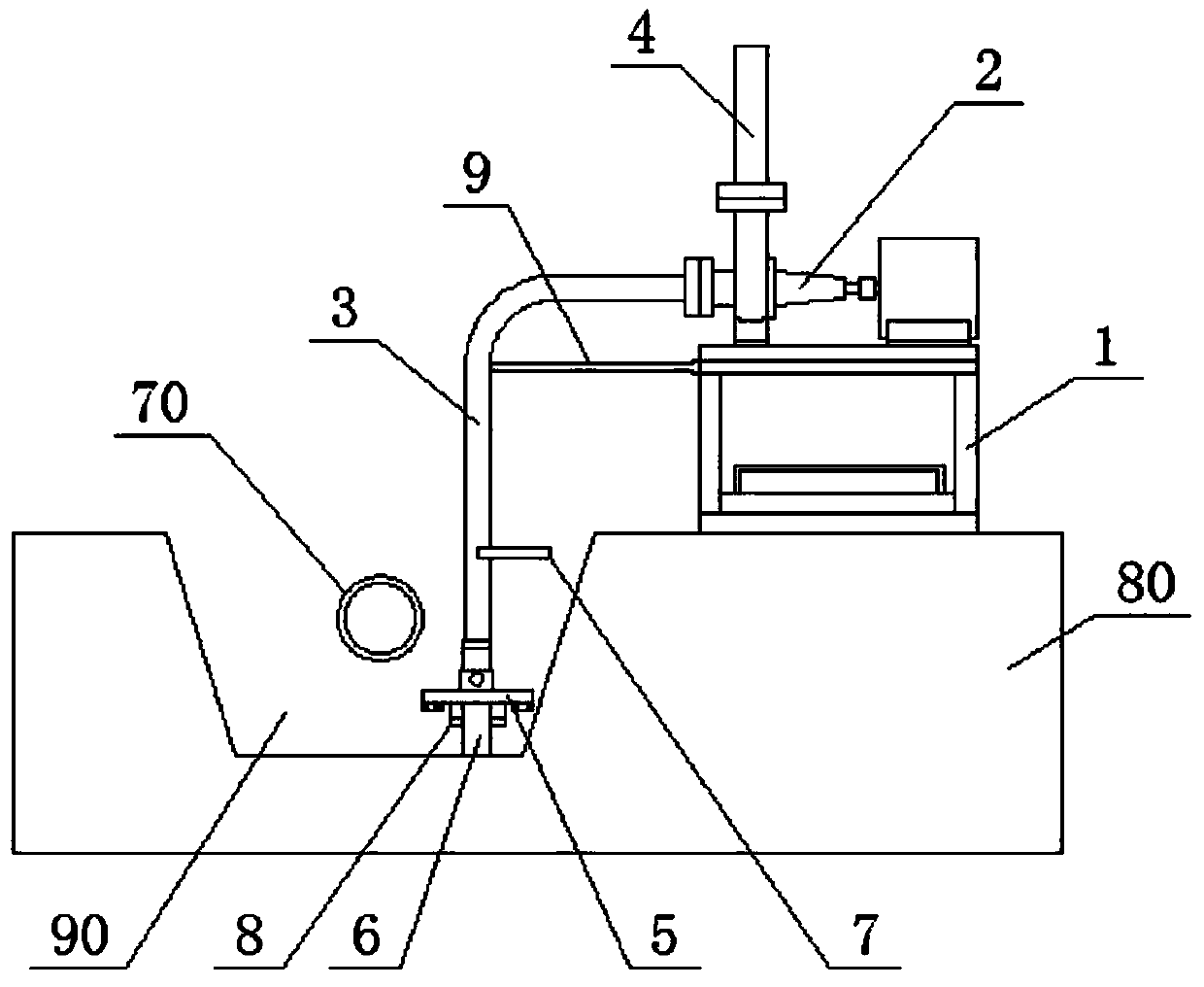

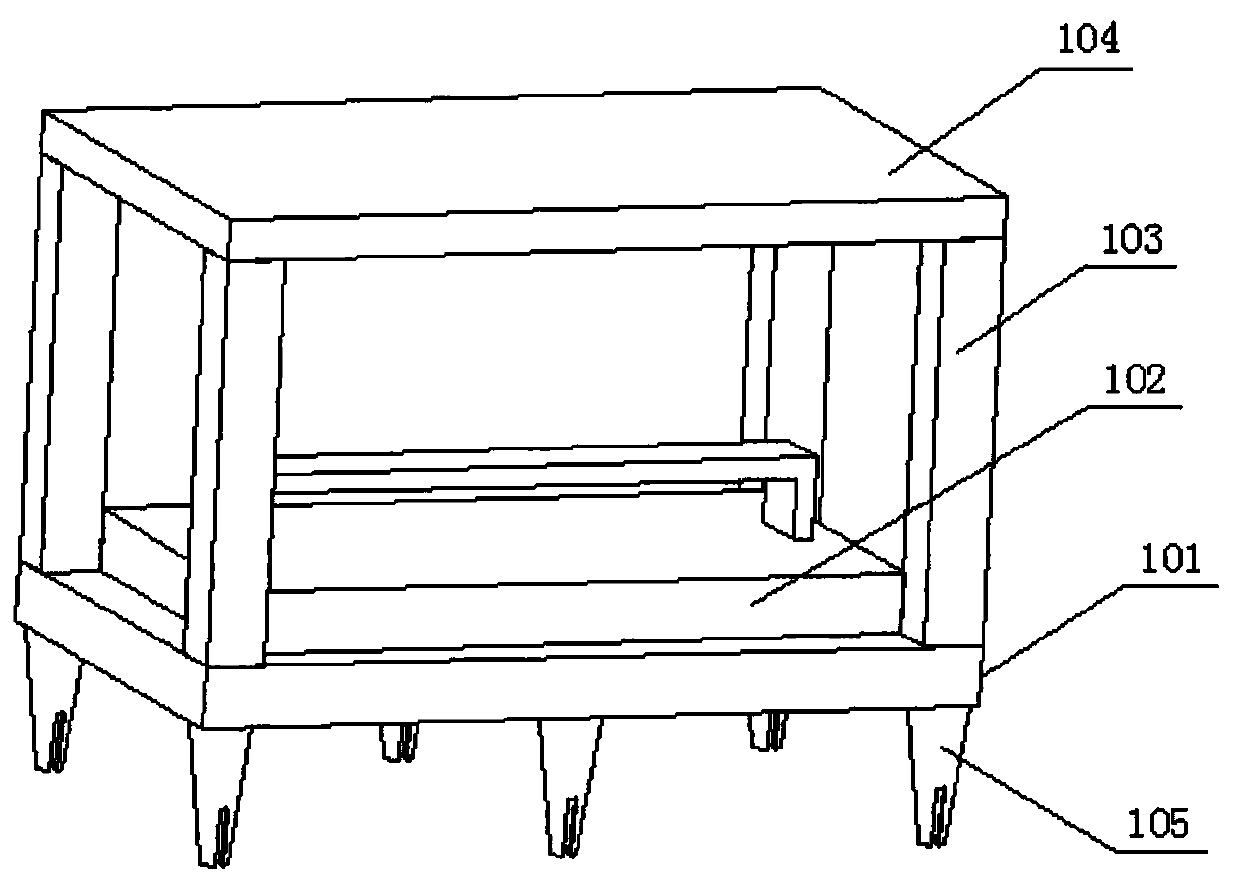

[0043] Specifically, in figure 1 , figure 2 , image 3 , Figure 4 Wherein, the number of the supporting portion 1 is one; it includes a first plate 101 for placing a counterweight 102; four pillars 103 connected to the first plate 101; a second plate 104 connected to the The column 103 is used to connect the water pump 2; and the plug 105 is connected to the first plate 101 and is used to insert the ground 80;

[0044] The insert 105 is an inverted tapered tube, and two first through grooves 105-1 are provided on the side wall; the length of the first through groove 105-1 after plane projection is that of the insert 105 after plane projection 1 / 3 of the length dimension;

[0045] The first plate 101 is a tetragonal steel plate, and a groove is left in the middle to facilitate the placement of at least one counterweight 102;

[0046] The counterweight 102 is cast and placed on the first plate 101 by a forklift, so that the supporting portion 1 can be better supported on the ground ...

Embodiment 2

[0078] Specifically, in Picture 11 Two sets of drainage devices are provided on both sides of the gas pipeline 70 to make the operation more convenient for the operator;

[0079] The working principle of the present invention: when implemented, the support 1 is set on the ground 80 to form a reliable support, so that the water pump 2 can be reliably positioned, and it has good stability during operation, and can drain the water in the excavation groove 90 , To prevent excessive water from passing through the first platform 5, affecting the operation of the operator; the first platform 5 is provided, and the position of the first platform 5 can be adjusted through the support 6, so that the operator can well control the gas pipeline 70 The position between the two is easy to operate; the second platform 7 is provided to form a ladder structure, which is convenient for operators to climb, reduces the probability of slipping, and has better safety; thereby overcoming the inconvenie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com