Torque detection table

A technology of torque detection and detection, which is applied in the field of detection equipment, can solve the problems of unsuitable production line batch detection, etc., and achieve the effect of simple structure, wide application range and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The embodiments of the present invention are described in detail below. This embodiment is implemented on the premise of the technical solution of the present invention, and detailed implementation methods and specific operating procedures are provided, but the protection scope of the present invention is not limited to the following implementation example.

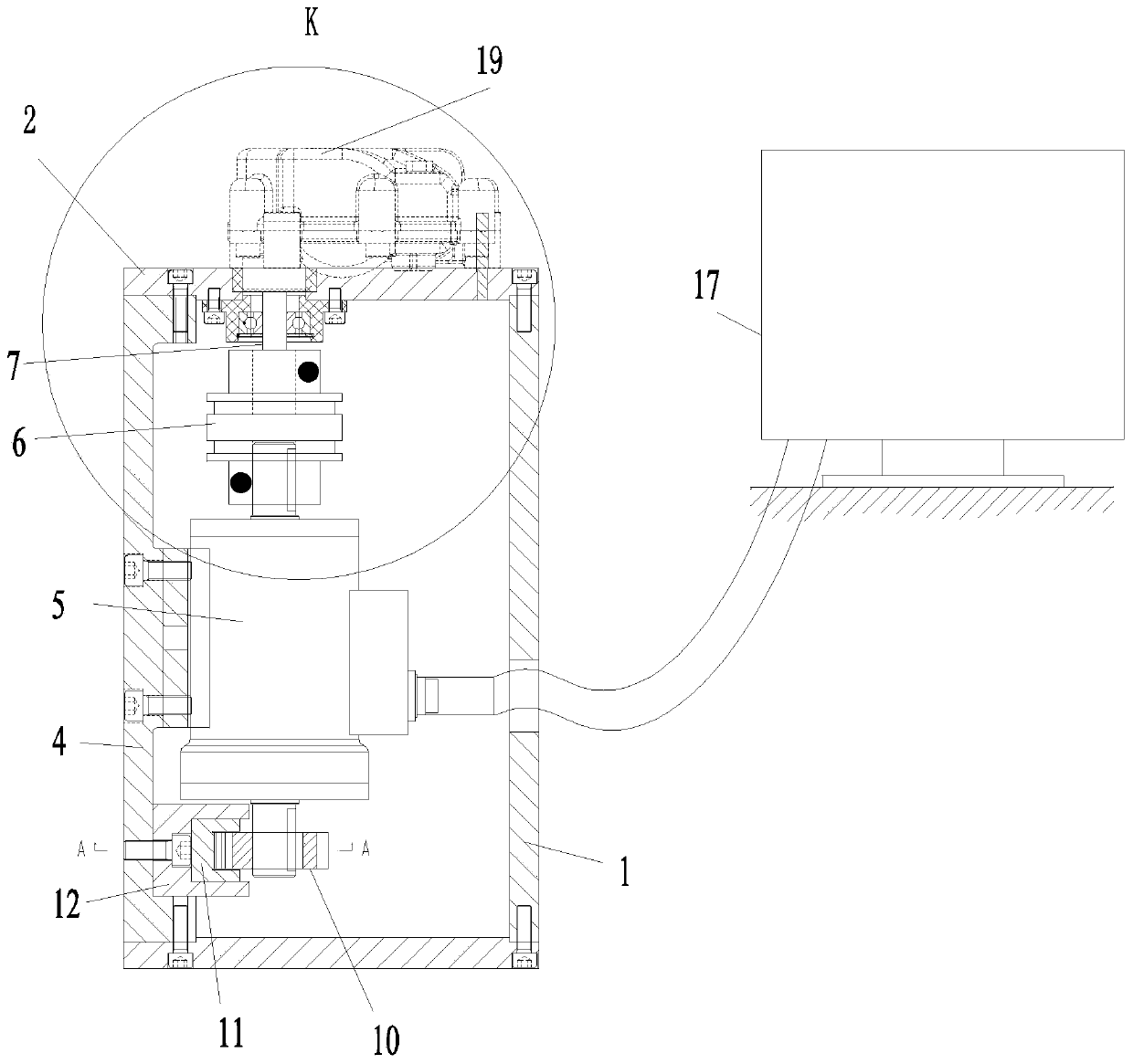

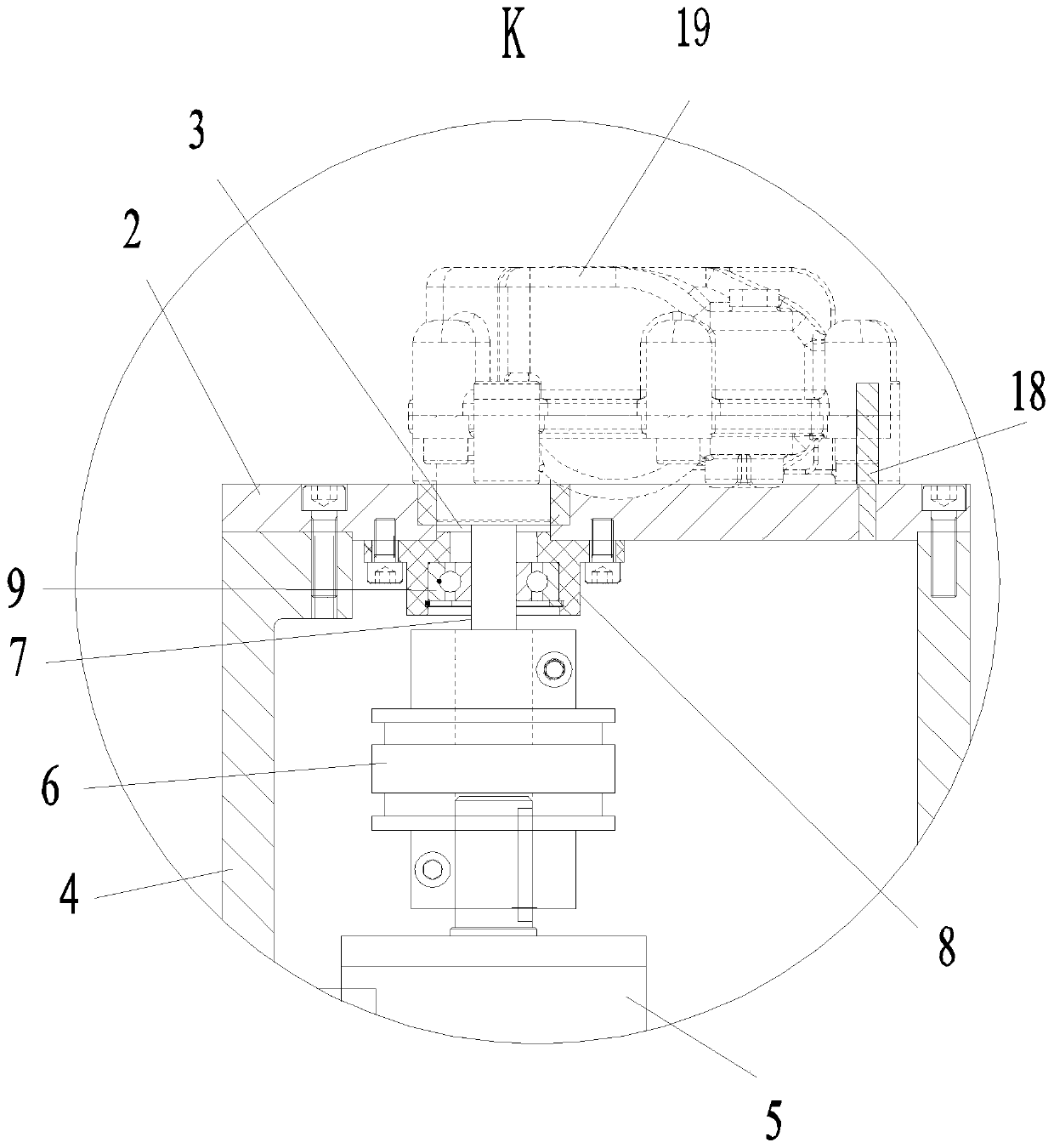

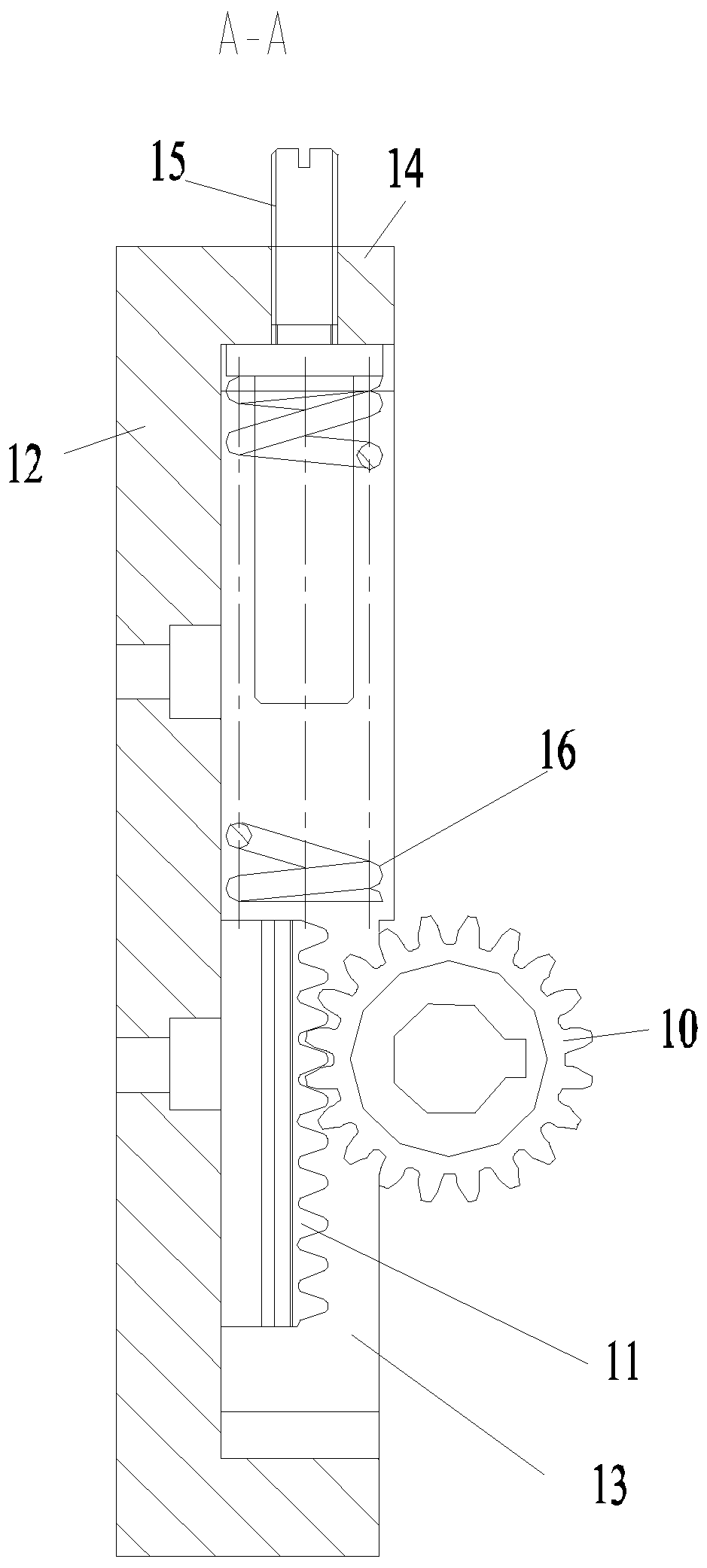

[0018] see Figure 1 to Figure 4 , the present embodiment discloses a torque detection platform, which includes a box body 1, the top plate of the box body 1 is a guide plate 2, one of the side plates of the box body 1 is a mounting plate 4, and the inner side of the mounting plate 4 is fixed by screws. A torque speed sensor 5, the torque speed sensor 5 can be a torque speed sensor 5 of the model WDH-GT, the input shaft of the torque speed sensor 5 extends vertically upwards and is connected with a guide shaft 7 through a coupling 6 , there is a perforation 3 on the guide plate 2, the product to be tested is insta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com