Board online follow-up fixed-distance punching device

A punching device and sheet metal technology, applied in the field of mechanical stamping processing, can solve the problems of low processing precision, complicated operation, more manpower and time, and achieve the effect of reducing labor intensity and improving quality and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

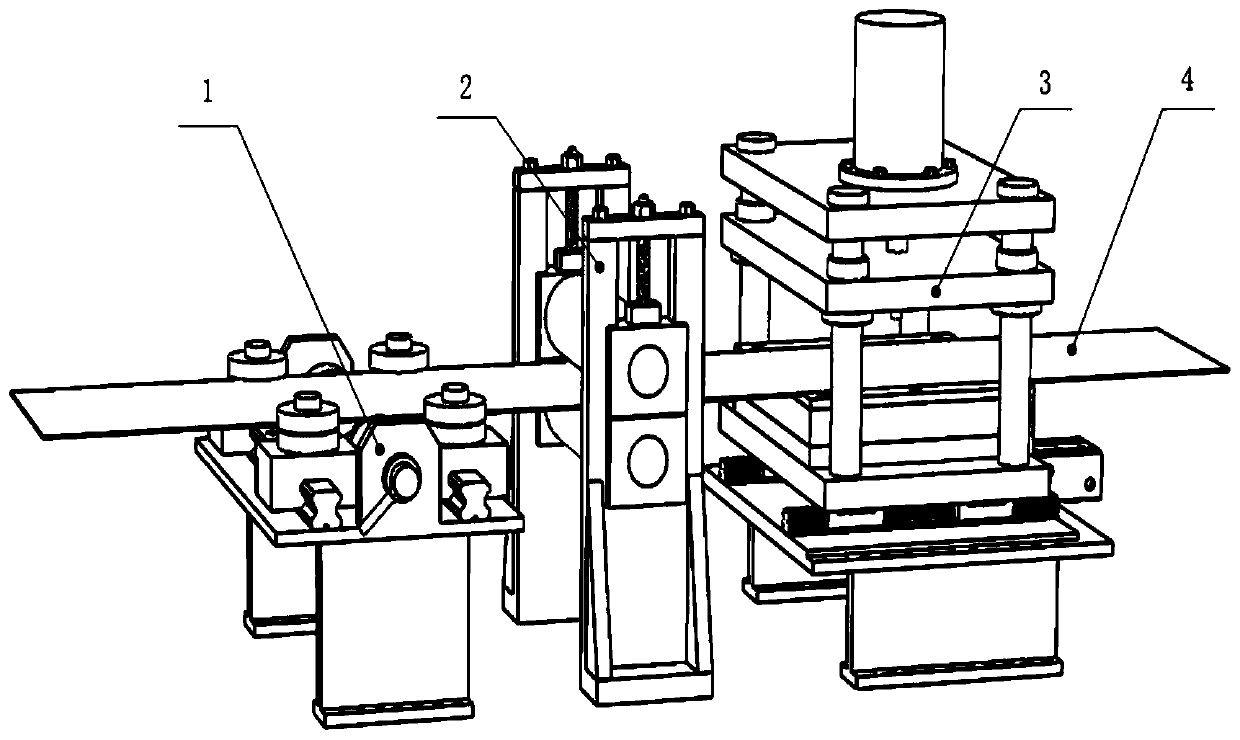

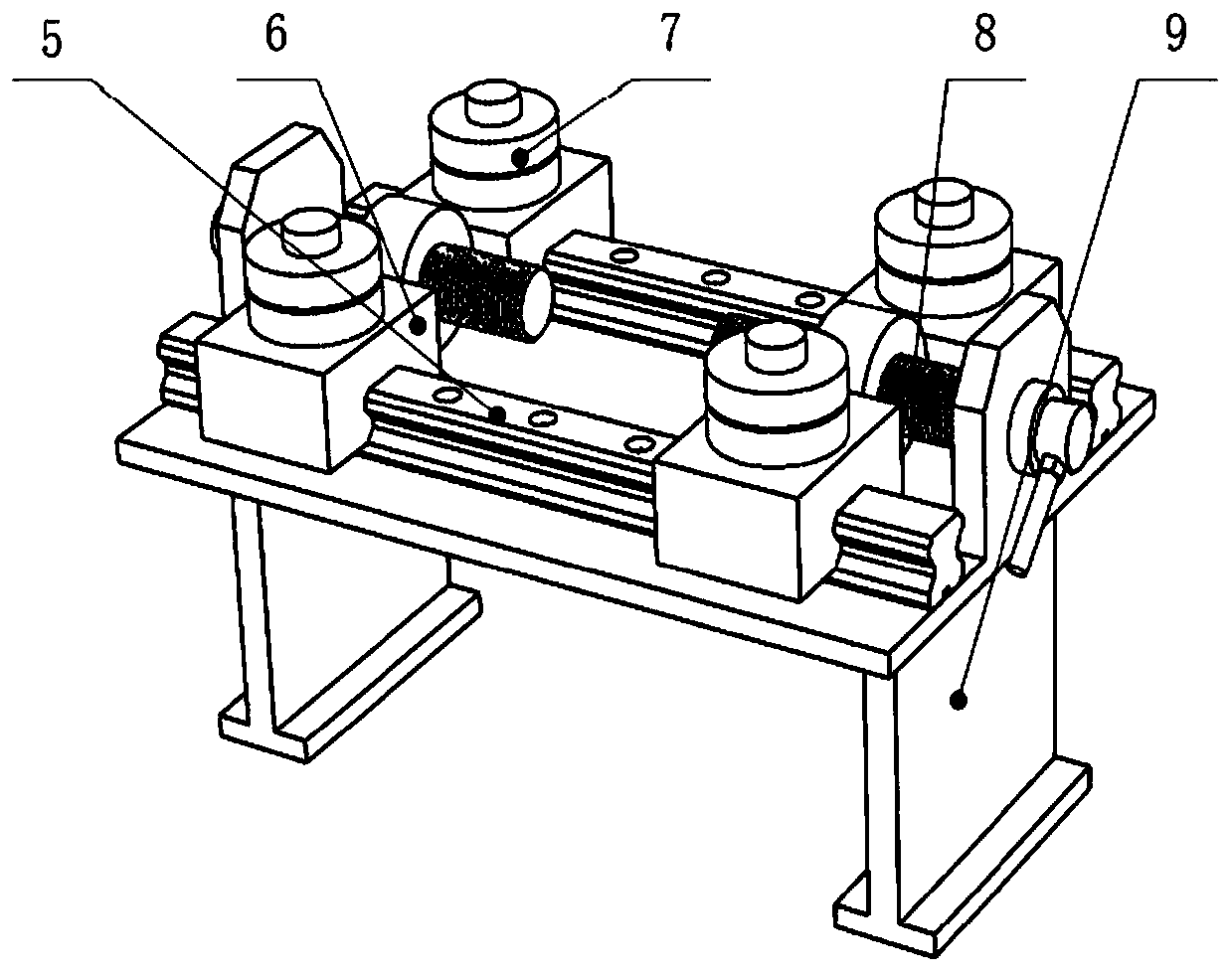

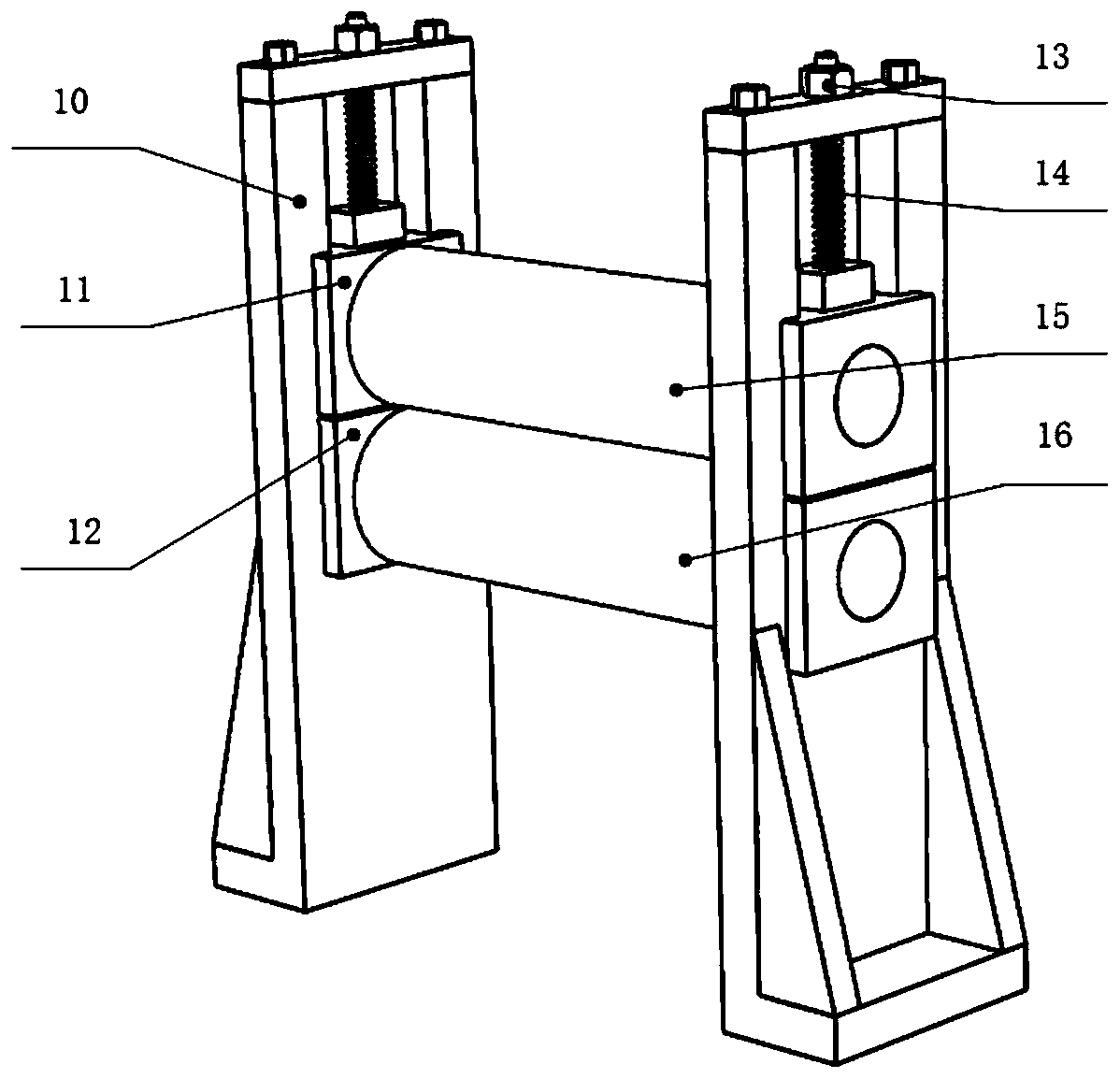

[0014] The invention provides an online follow-up and fixed-distance punching device for sheet metal, which includes a sheet material positioning mechanism 1, a measuring roller mechanism 2, and a follow-up punching mechanism 3, which can realize the positioning, speed measurement and distance measurement of different types of sheets 4 online And follow-up fixed-distance punching. Its working principle is: under the pinch of the feeding mechanism, the sheet material 4 successively passes between the four guide wheels 7 of the sheet material positioning mechanism 1, the upper measuring roller 15 and the lower measuring roller mechanism 2 of the measuring roller mechanism 2. between the rollers 16 and the upper part of the die 23 of the follow-up punching mechanism 3 . By adjusting the screw nut assembly 8 in the plate positioning mechanism 1 to adapt to the positioning of the plate 4 of different sizes, the upper measuring roller 15 and the measuring roller mechanism 2 The low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com