Accumulation method for grillwork particle composite bed

A particle compounding and lattice technology, which is applied in the field of realizing the orderly stacked bed of composite particles, can solve the problems that the composite stacked bed cannot be absolutely ordered, the stacked bed is difficult to realize, and the orderly and controllable stacking structure cannot be guaranteed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] Accompanying drawing is the specific embodiment of the present invention.

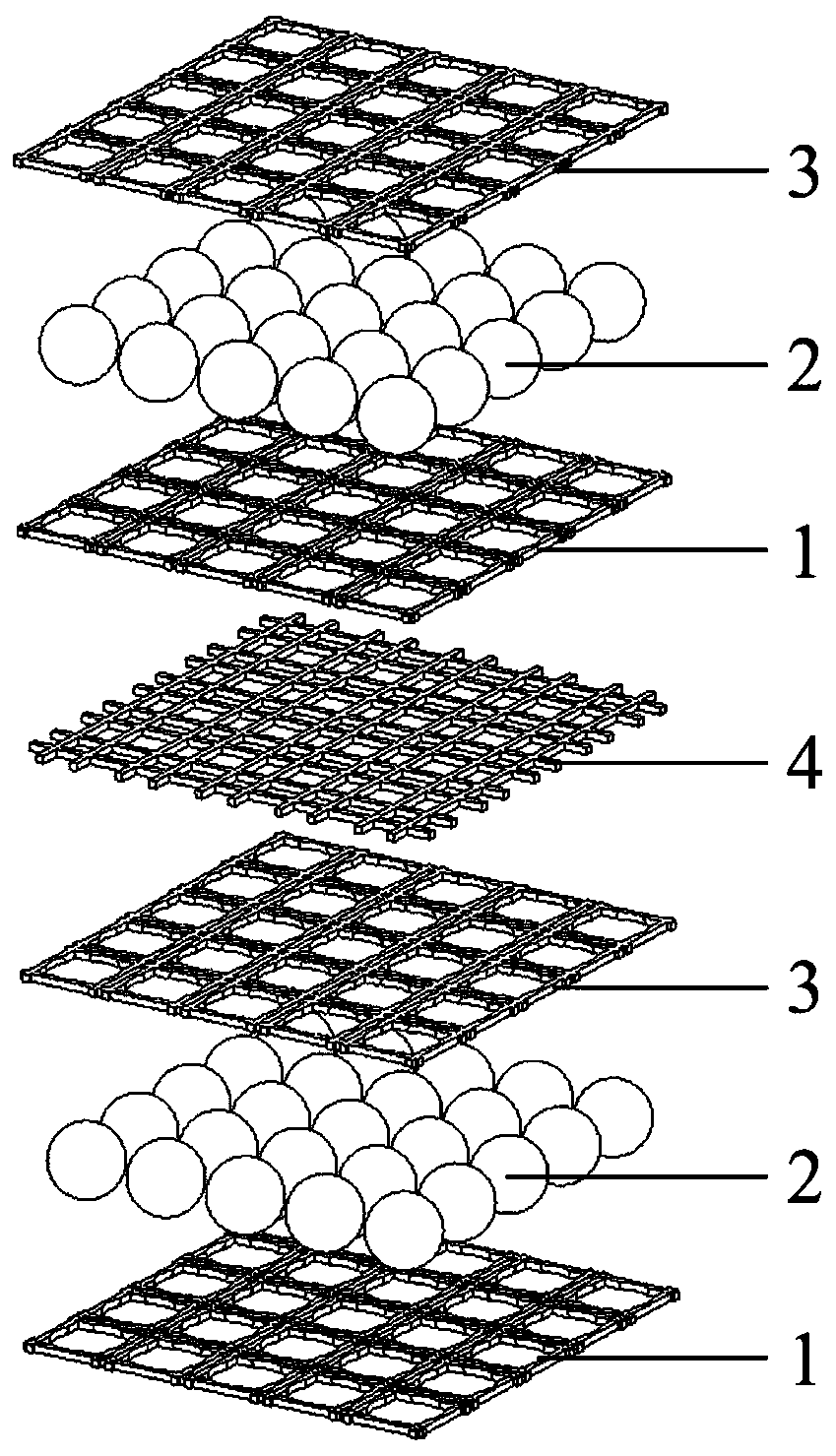

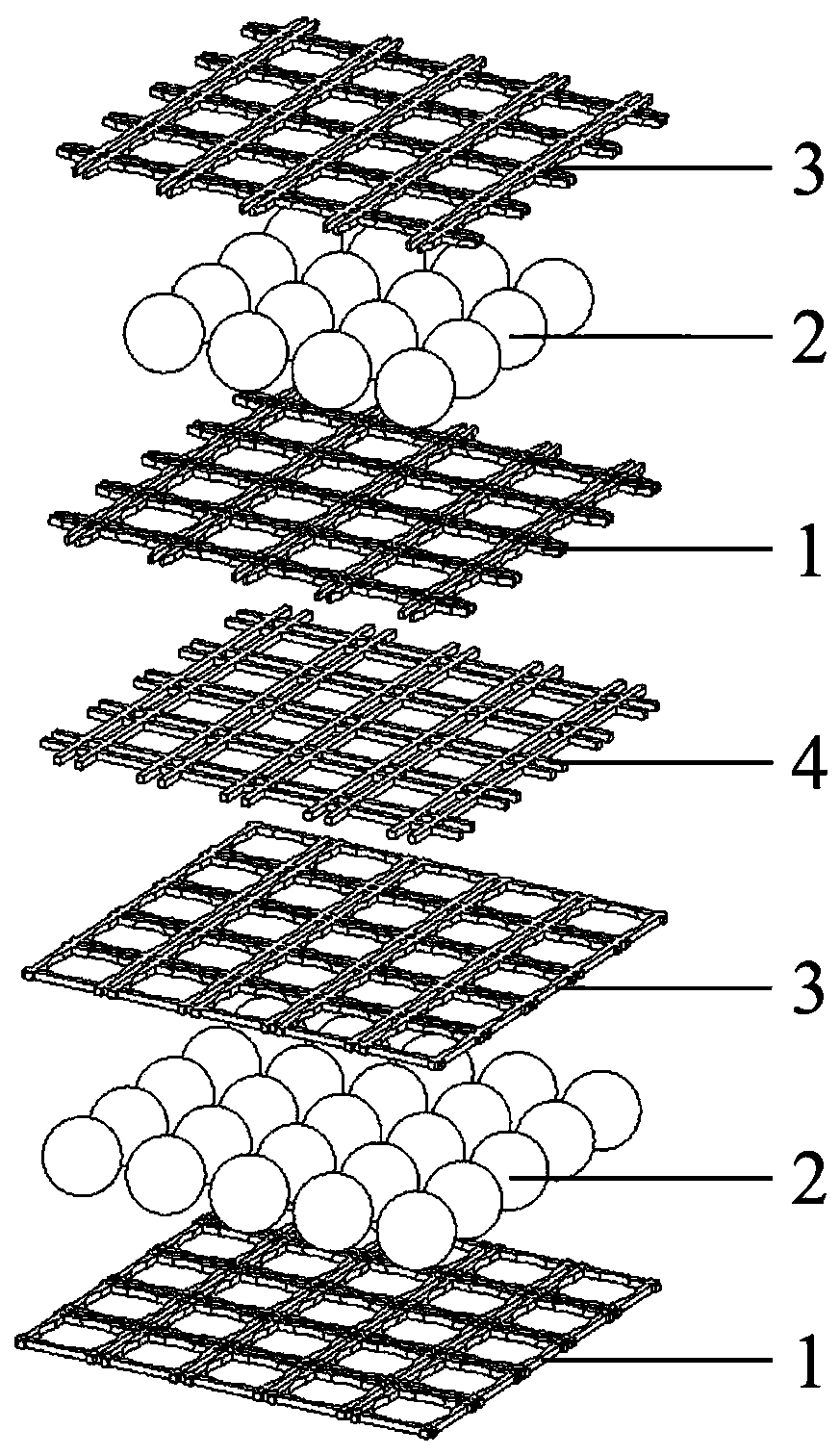

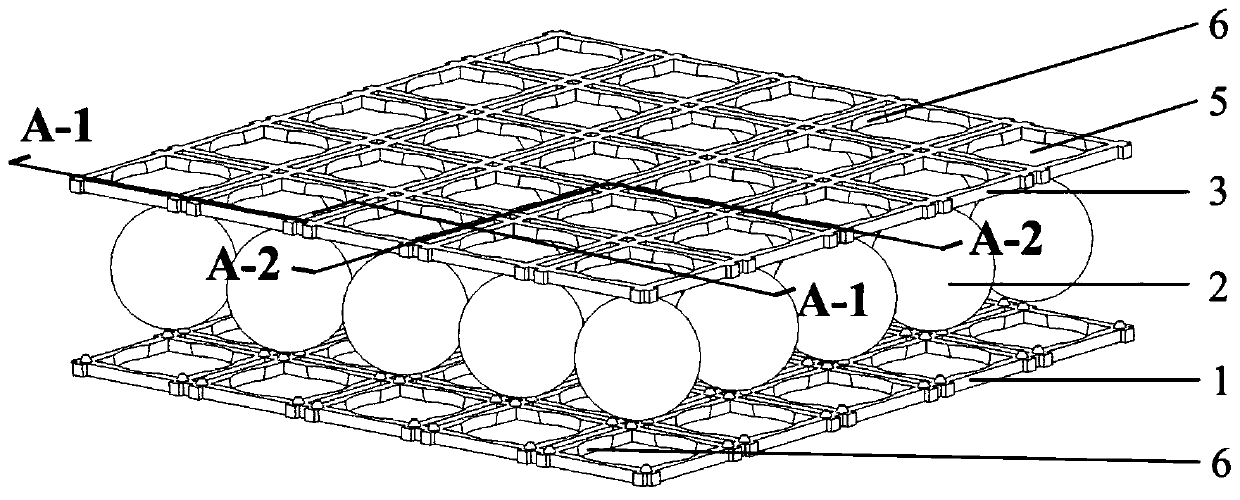

[0026] As shown in Figure 1, the present invention provides a method for realizing an ordered particle packing bed, which can realize different ordered packing modes, not just a single one, Figure 1(a) and Figure 1(b ) gives two typical ordered structures, which are particle parallel packing structure and particle interlacing packing structure. The method for realizing the ordered stacked bed proposed by the present invention is as follows: firstly use the lower spacer grid 1 and the upper spacer grid 3 to block several spherical particles 2 to form a whole spherical layer, and then put it from the top of the container to make it Fall freely to the bottom end under the action of gravity; then put the supporting grid 4 on the top of the container to make it fall freely to the lower layer of particles; then put down the ball layer assembled with the positioning grid from the top of the container, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com