Preparation method of bionic high-strength high-flexibility nano composite fiber

A nano-composite fiber, high-strength and high-toughness technology, applied in the direction of wet spinning, inorganic raw material artificial filament, etc., can solve the problems of small size of nano-materials and difficult direct application, etc., and achieve low cost, stable assembly process and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

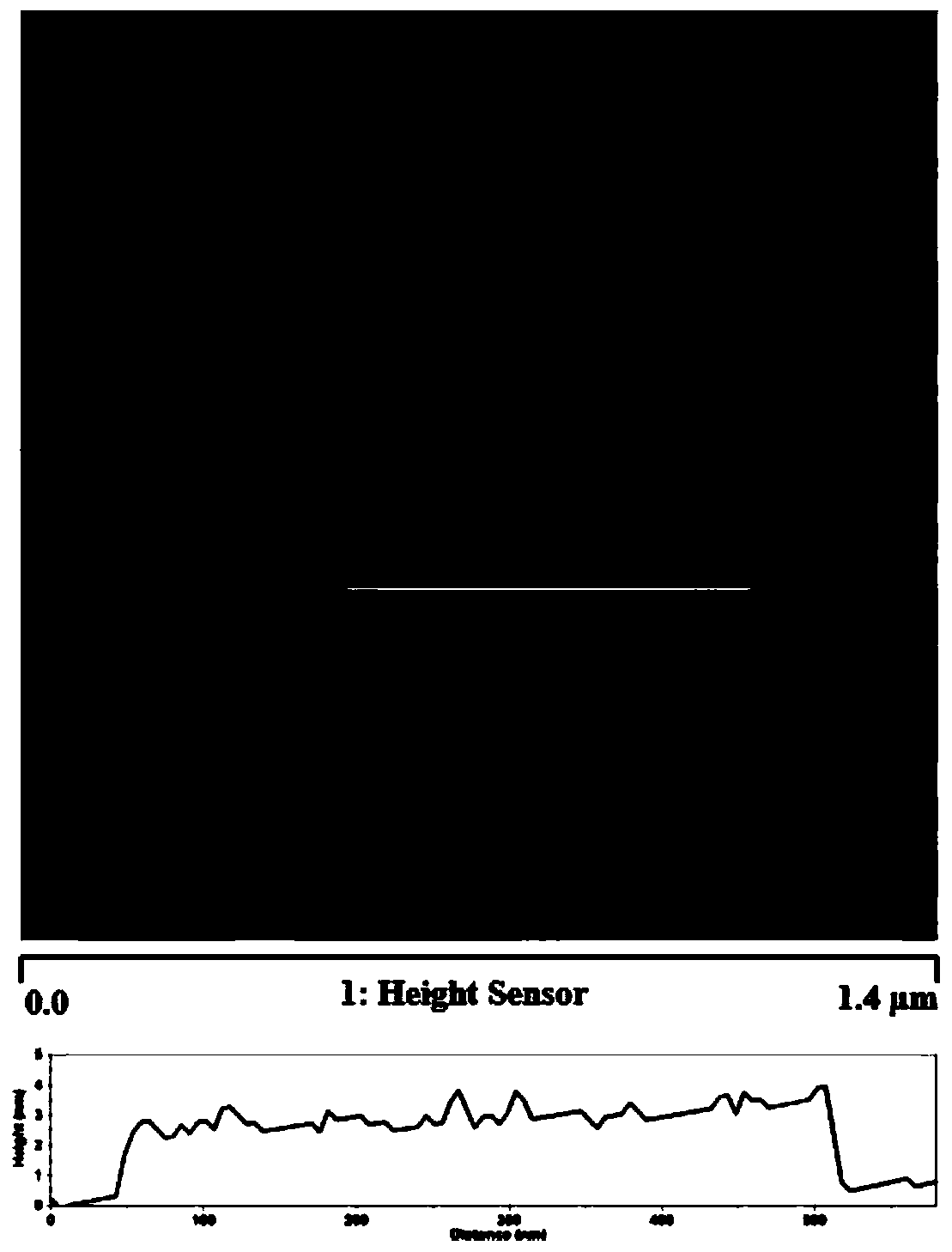

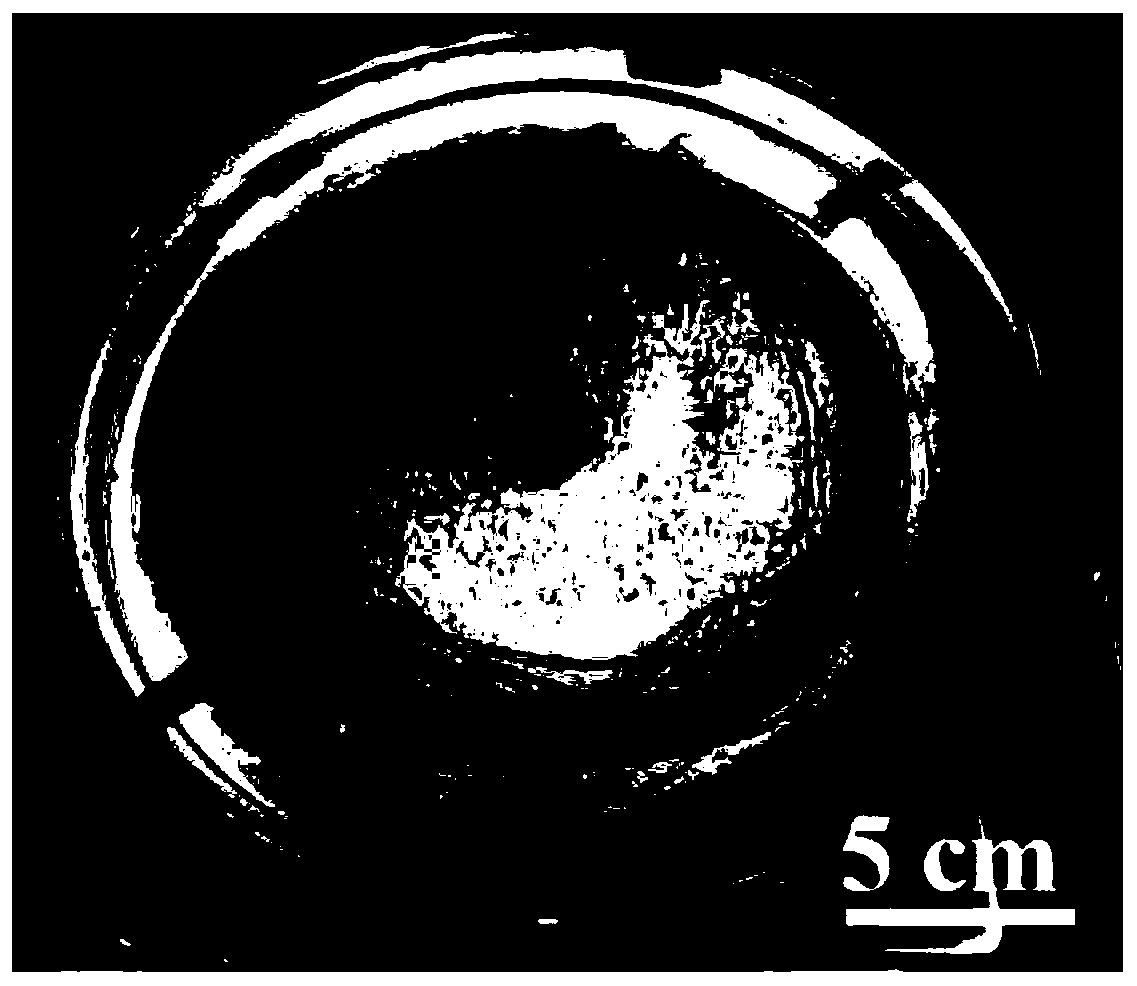

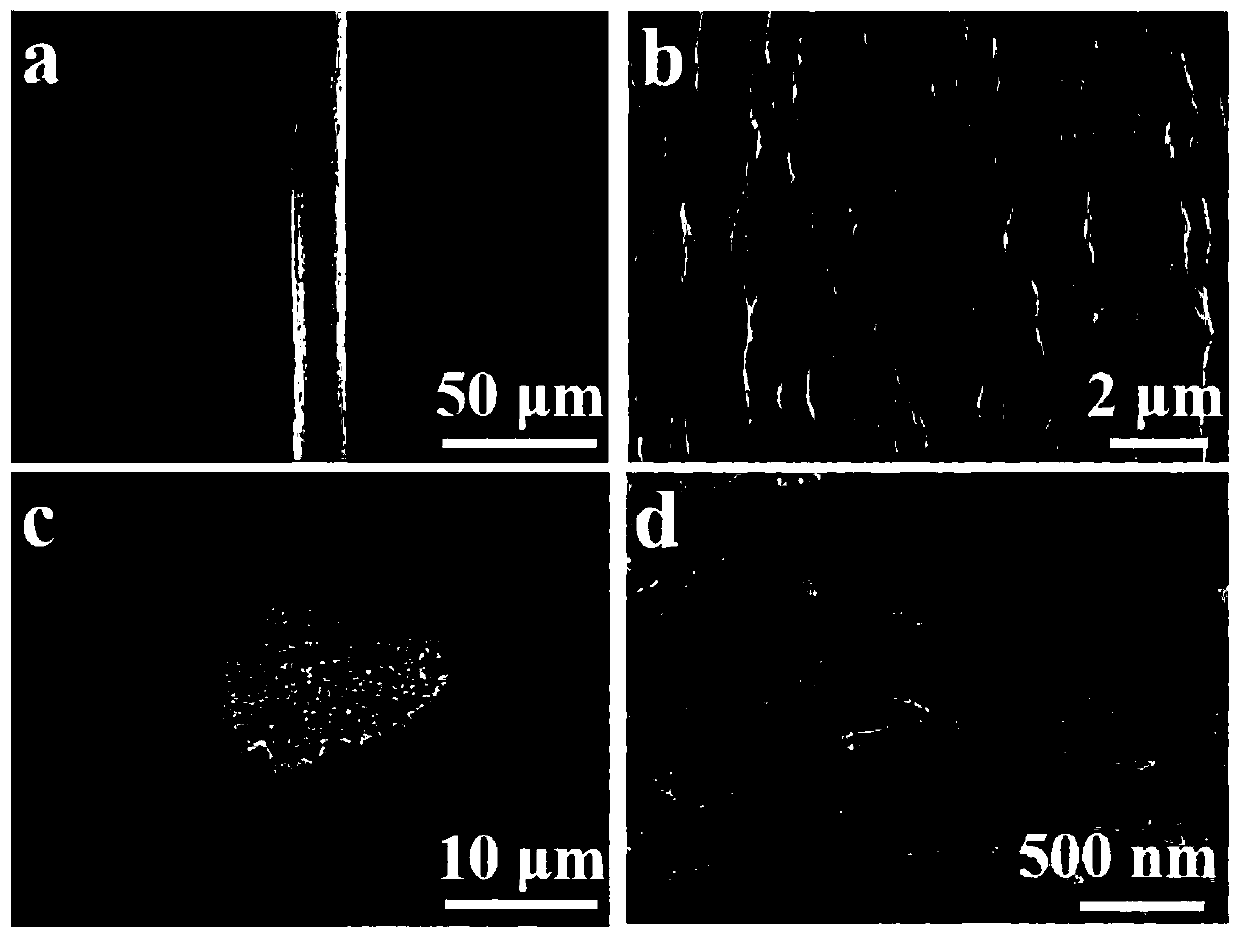

[0034] Preparation method of bionic high-strength and high-toughness graphene oxide-zirconia nanocomposite fibers

[0035] In the first step, prepare 50 mL of buffer solution with a pH value of 7.5 at room temperature, and stir for 10-30 minutes to obtain a uniformly mixed solution;

[0036] In the second step, take the homogeneously mixed solution obtained in the first step, add 5 mg of graphene oxide, stir at room temperature, and ultrasonically disperse evenly to obtain a brown-yellow graphene oxide solution with a mass concentration of 0.1 g / L;

[0037] In the third step, 14 mg of zirconium oxychloride octahydrate was added to the graphene oxide solution obtained in the second step, and the temperature was controlled at 25° C. and stirred for 30 minutes to obtain a uniformly mixed solution;

[0038] In the fourth step, heat the homogeneously mixed solution obtained in the third step to 60°C and continue to stir for 3 hours, then cool down to room temperature naturally, ult...

Embodiment 2

[0044] Preparation method of biomimetic high-toughness graphene oxide-zirconia nanocomposite fibers

[0045] The first step is to prepare 50mL buffer solution with a pH value of 7.5 at room temperature, and after stirring for 10-30min, a uniformly mixed solution can be obtained;

[0046] In the second step, take the homogeneously mixed solution obtained in the first step, add 5 mg of graphene oxide, stir at room temperature, and ultrasonically disperse evenly to obtain a brown-yellow graphene oxide solution with a mass concentration of 0.1 g / L;

[0047] In the third step, 8 mg of zirconium oxychloride octahydrate was added to the graphene oxide solution obtained in the second step, and the temperature was controlled at 25° C. and stirred for 30 minutes to obtain a uniformly mixed solution;

[0048] In the fourth step, heat the homogeneously mixed solution obtained in the third step to 40° C., and continue to stir for 2 hours, then cool down to room temperature naturally, ultraso...

Embodiment 3

[0054] Preparation method of biomimetic graphene oxide nanocomposite fiber

[0055] The first step is to take a certain amount of graphene oxide, add it to water, and prepare a graphene oxide spinning solution with a concentration of 5g / L, and disperse it evenly by ultrasonication for 2 hours;

[0056] The second step is to prepare an ethanol-water coagulation bath containing 5wt% calcium chloride, 0.5wt% polyvinyl alcohol and 0.005wt% glutaraldehyde, wherein the volume ratio of ethanol to water is 1:3, and it is obtained after stirring and ultrasonic Mix uniform coagulation bath solution;

[0057] The third step is to inject the uniformly dispersed spinning solution obtained in the first step into the syringe, inject it into the coagulation bath obtained in the second step at a rate of 0.13mL / min, and let it stand for 0.5h to obtain the gel fiber;

[0058] In the fourth step, the gel fiber obtained in the third step is washed and dried naturally, and then heat-treated at a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com