Multifunctional protective guardrail for construction site

A technology for protective railings and construction sites, which is applied to buildings, building types, fences, etc., can solve the problems of complicated disassembly and assembly of protective railings, waste of materials, wind resistance, etc., to meet the requirements of safe and civilized construction, improve typhoon resistance, and connect well-structured effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

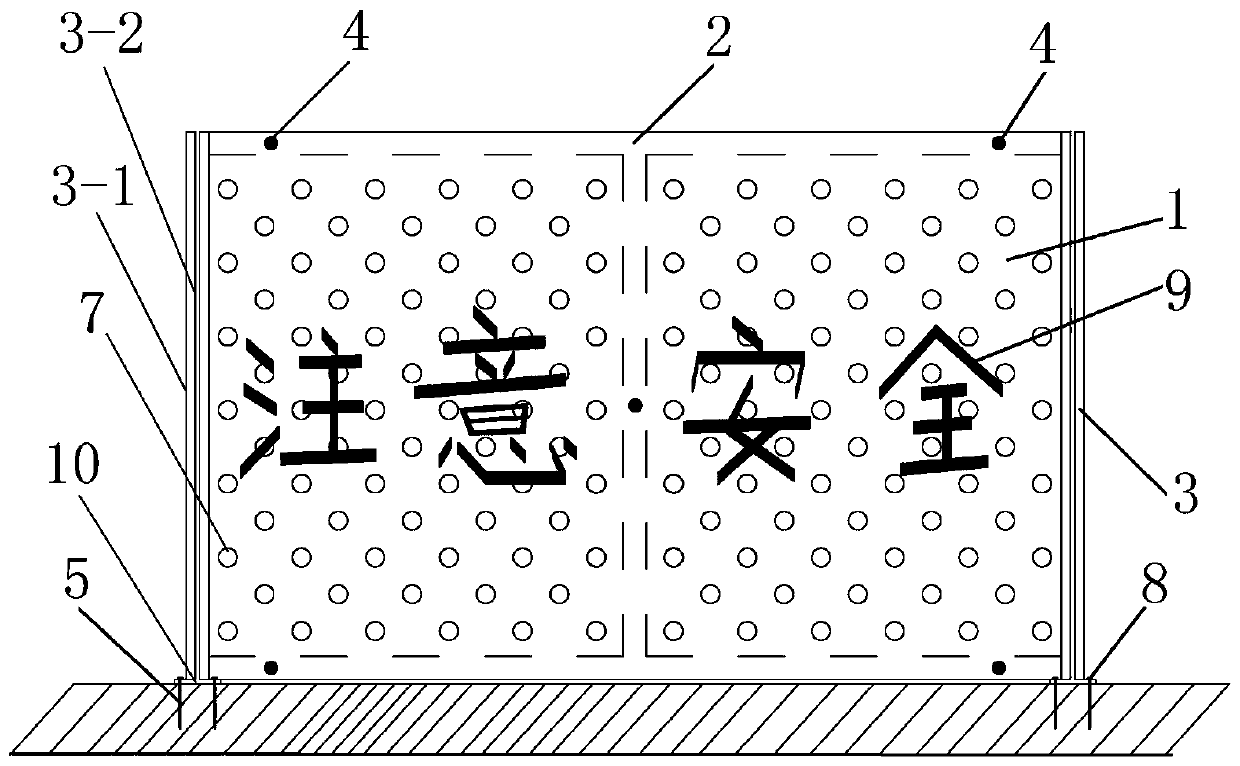

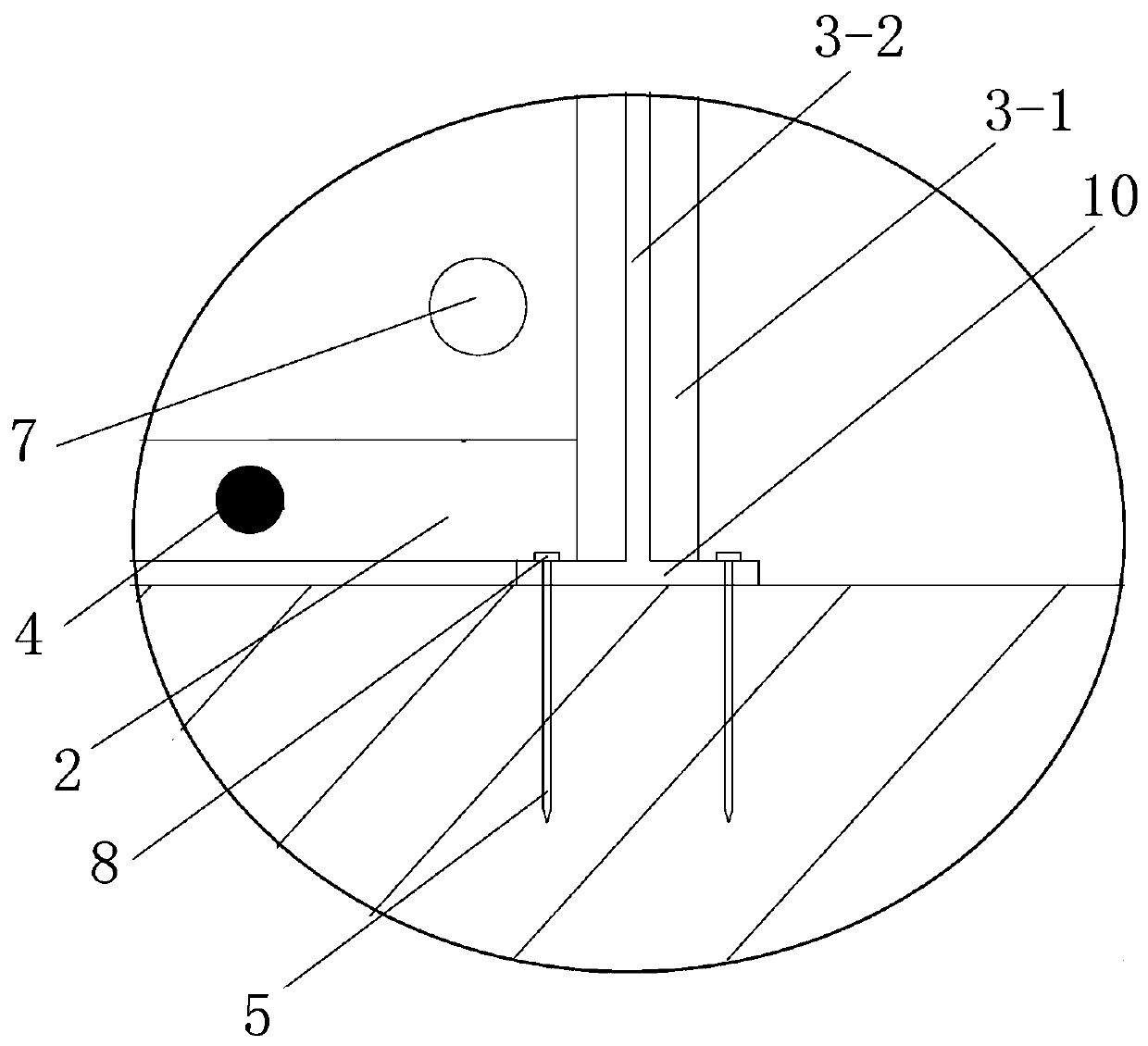

[0021] Embodiment 1, a kind of construction site multifunctional protective railing, such as figure 1 As shown, it includes three supporting rods 3 arranged at intervals, and the supporting rods 3 are fixedly arranged in the concrete through expansion bolts 5 . Such as image 3 As shown, the lower end of the support rod 3 is welded on the fixed steel plate 10, and the fixed steel plate 10 is fixed above the concrete through the expansion bolt 5 and the nut 8 for fastening. , can fully guarantee the reliability and stability of the connection between the support rod 3 and the building.

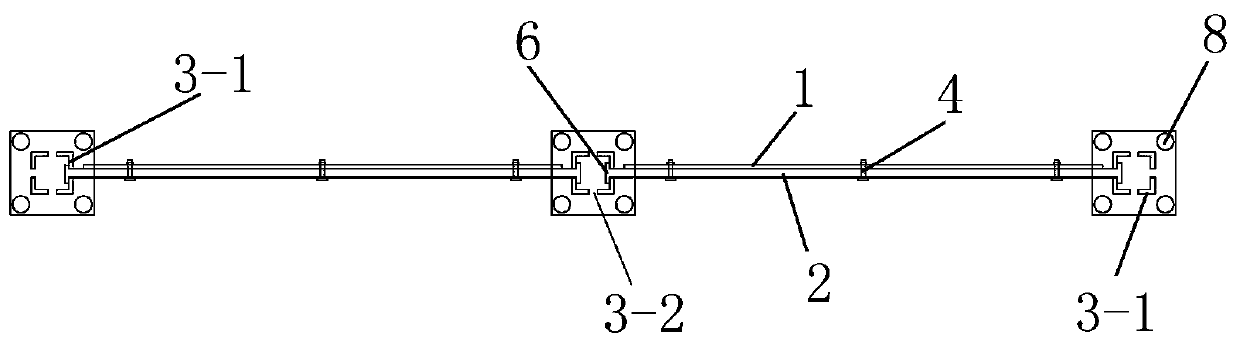

[0022] Such as figure 2 As shown, each support rod 3 includes four angle steels 3-1 arranged in parallel, and the four angle steels 3-1 encircle a support rod 3 with a rectangular cross section, and the four angle steels 3-1 are arranged at intervals to form four front, rear, left, and right sides. A vertical installation slot 3-2, the end of the stabilizing rod 2 is clamped in the installa...

Embodiment 2

[0025] Embodiment 2, a multi-functional protective railing on a construction site, the air holes 7 are provided with several, and the several air holes 7 are arranged in a plum blossom shape on the publicity protection board 1, which can not only ensure the wind resistance, but also have a beautiful appearance and It is convenient for hole making processing.

[0026] Other structures of this embodiment are the same as those of Embodiment 1.

Embodiment 3

[0027] Embodiment 3 is a multifunctional protective railing on a construction site. The propaganda protection plate 1 is detachably connected to the stabilizing rod 2 through bolts 4, and the propaganda protection plate 1 is fixed by bolts 4 for easy disassembly and turnover.

[0028] Other structures of this embodiment are the same as Embodiment 1 or 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com