Discharging-exhausting cover, discharging system and cut tobacco drying equipment

A technology of exhaust hood and discharge port, which is applied in the fields of tobacco preparation, application, tobacco, etc., can solve the problems of waste, danger, inability to completely evaporate, etc., and achieve the effect of improving physical quality and eliminating water-stained smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

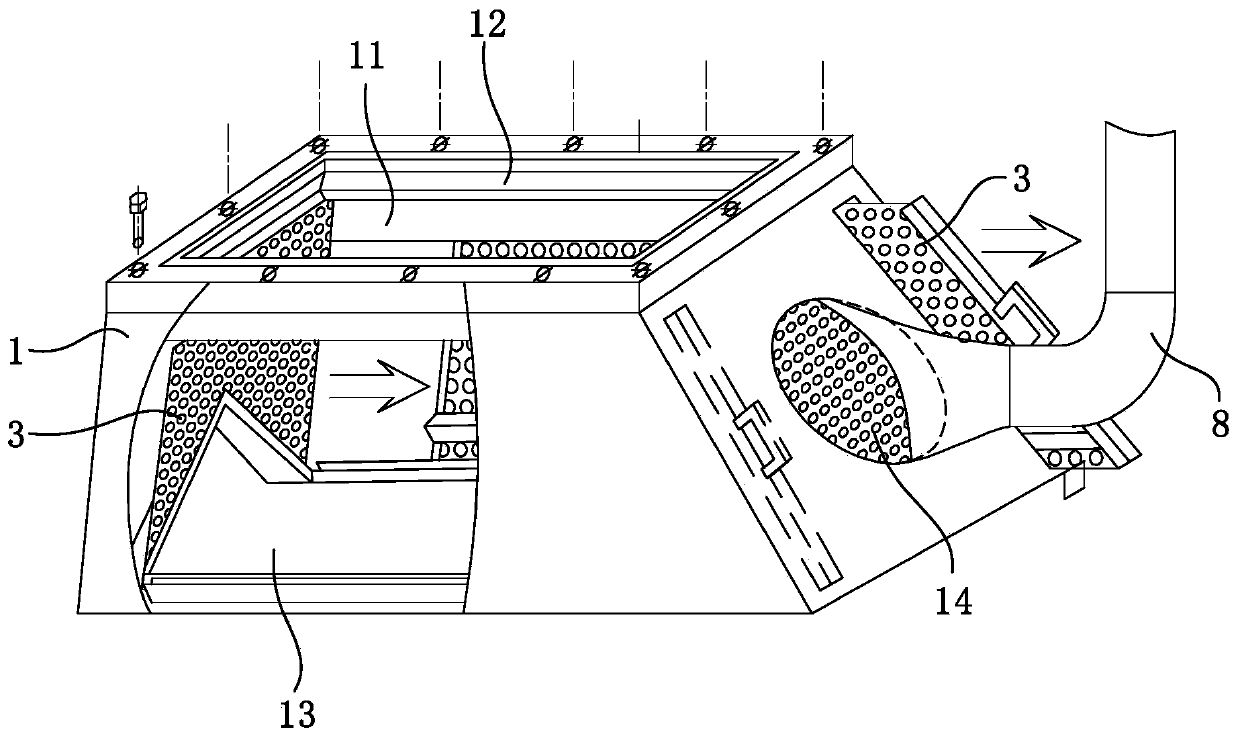

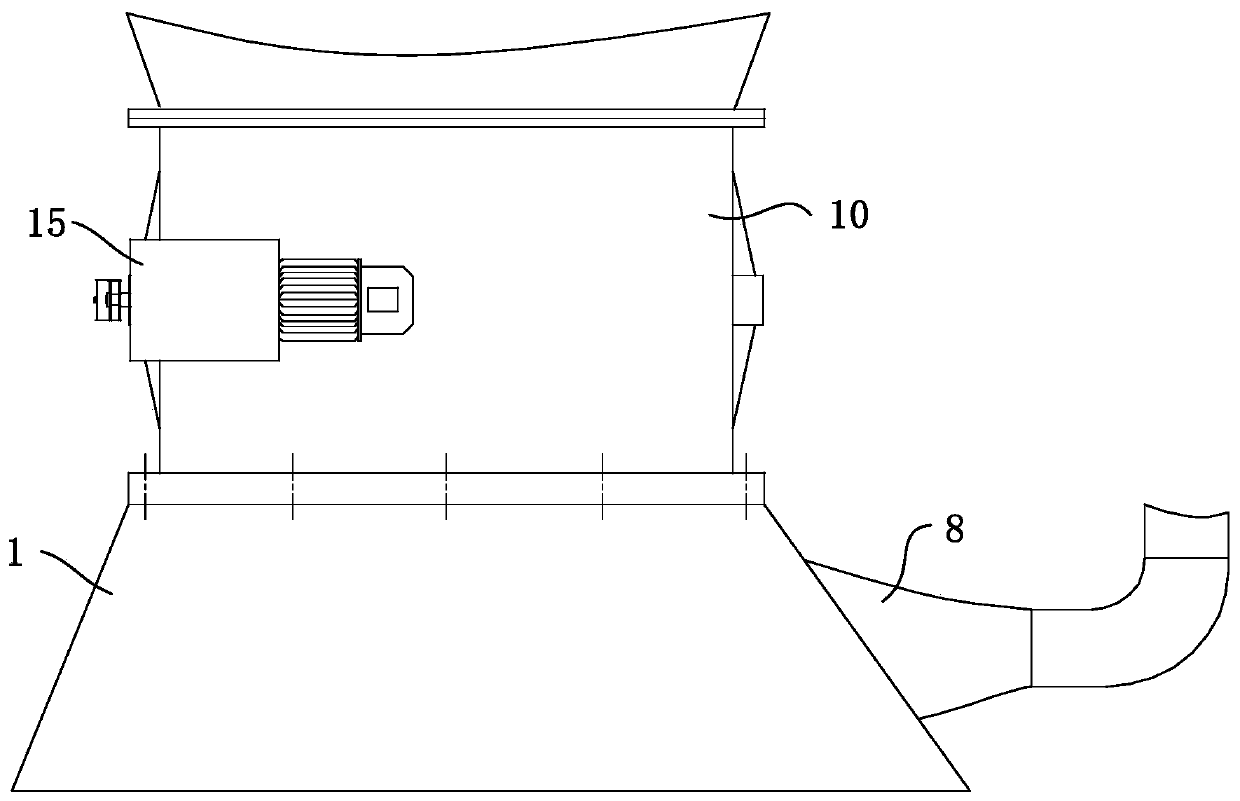

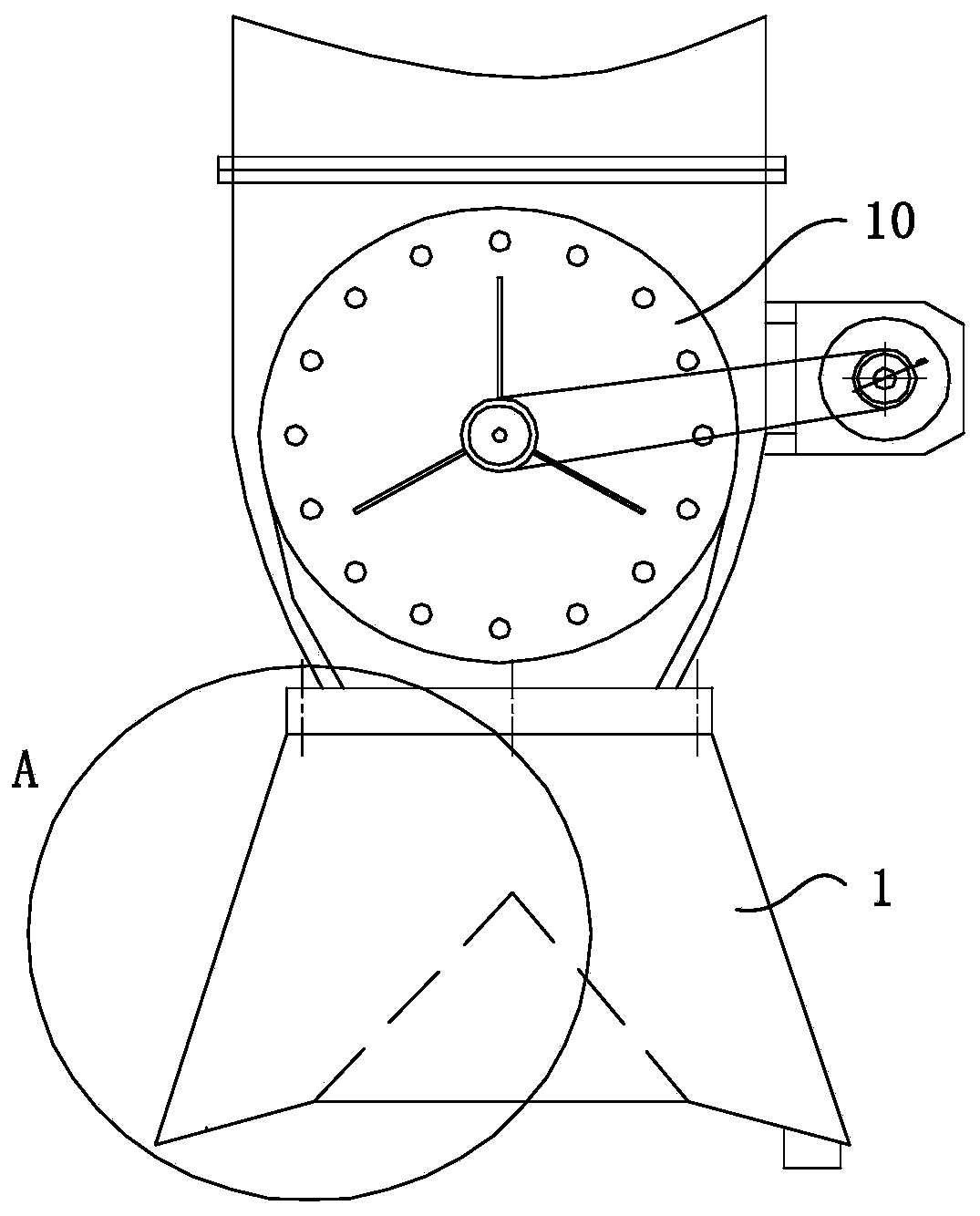

[0046] Combine below Figure 1 to Figure 5 The technical solution provided by the present invention is described in more detail.

[0047] see figure 1 , the embodiment of the present invention provides a discharge exhaust hood, which includes a hood 1 and a first water guiding component 2 . The cover body 1 is provided with an accommodating cavity 11 , a material inlet 12 , a first material outlet 13 and a second material outlet 14 . The material inlet 12 , the first material outlet 13 and the second material outlet 14 are all in communication with the accommodating cavity 11 . The first water guiding component 2 is installed inside the accommodating cavity 11 and is located below the material inlet 12 , and the first water guiding component 2 includes a protrusion protruding toward the inside of the accommodating cavity 11 .

[0048] The material inlet 12 is used to receive the mixture of material and water from the material outlet air lock 10, the first material outlet 13...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com