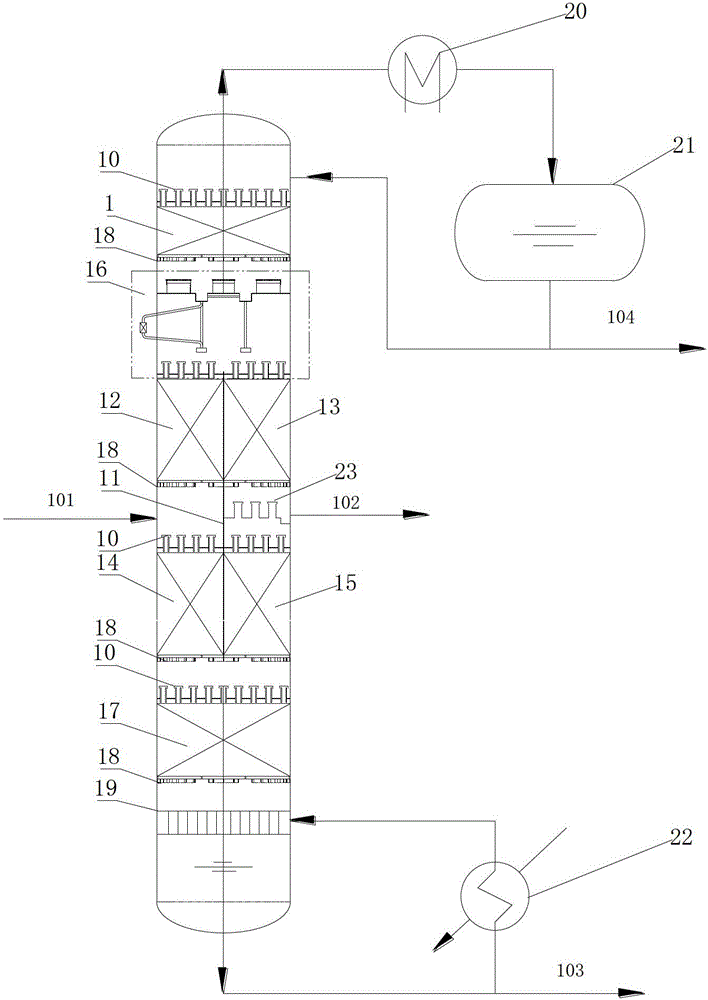

A kind of separator rectification method and device thereof regulated by liquid flow rate

A clapboard rectification and liquid phase flow rate technology, applied in the direction of distillation adjustment/control, fractionation, etc., can solve the problems of multiple equipment and complicated operation, and achieve the effects of ensuring stable operation, reducing floor space, and saving equipment investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] For the refining of 4,000 tons / year of trichlorosilane, the feed composition is as follows: chlorosilane mixture feed composition: 99wt% trichlorosilane, 0.5wt% dichlorodihydrosilane, and 0.5wt% silicon tetrachloride.

[0054] The feed flow rate is 4 tons / hour, the reflux flow / feed amount is 6, the tower top temperature is 62.7°C, the tower top pressure is 300kpa, and the pressure drop across the tower is 10kpa.

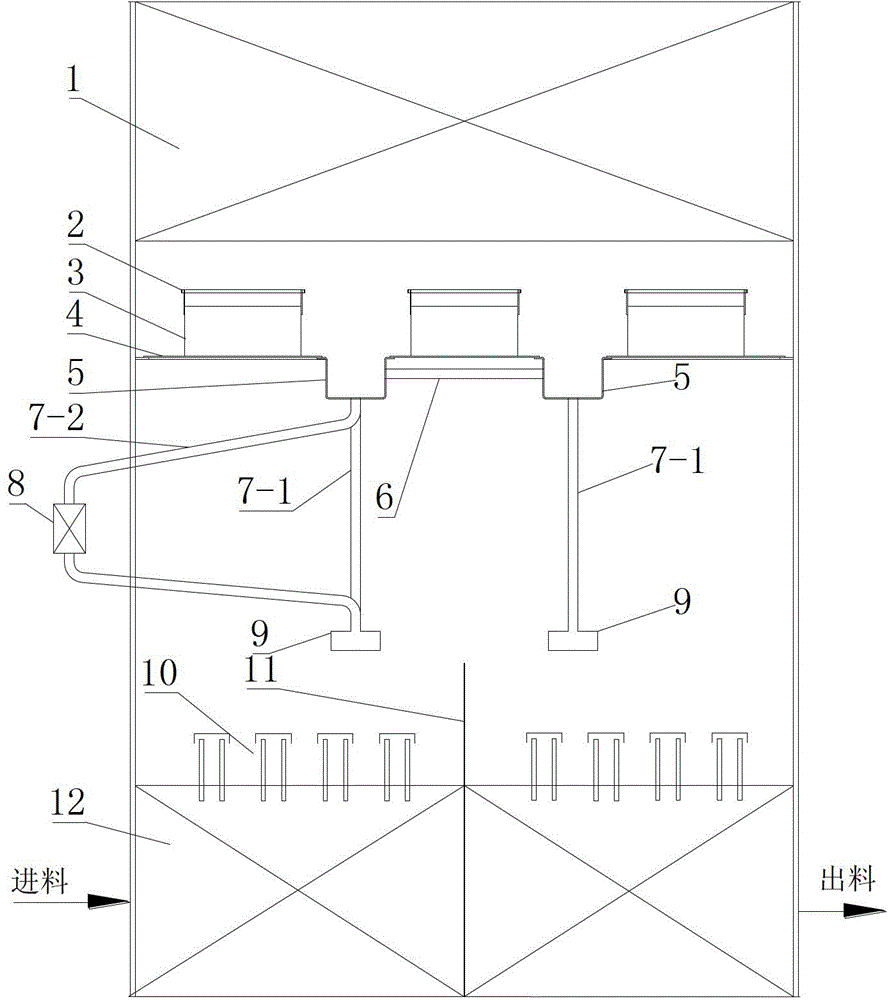

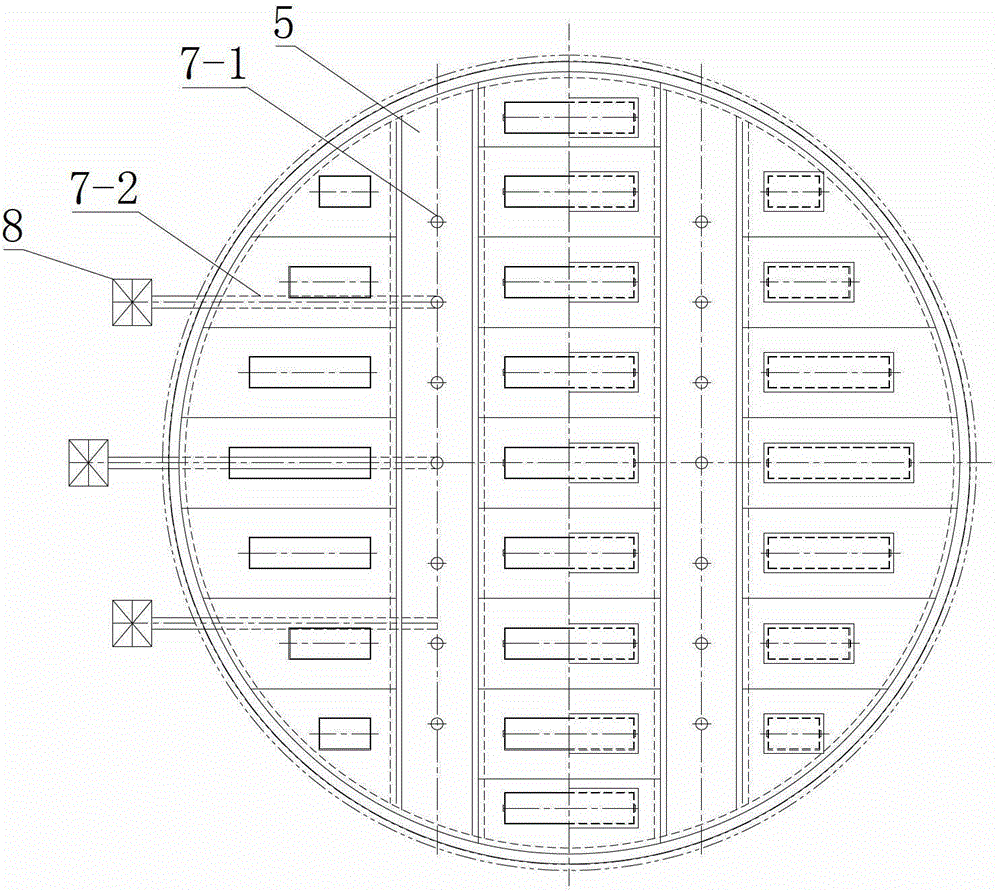

[0055] There are a total of 110 theoretical trays in the partitioned rectification column, of which there are 30 theoretical trays in the public rectification section, 30 theoretical trays in the common stripping section, and 50 theoretical trays in the partition section. At the 55th theoretical plate, the discharge position is located at the 54th theoretical plate. The liquid phase flow ratio on both sides of the partition is 1:1.4, which can be realized by setting the flow controller outside the tower by the method of the above example, and the trichlorosila...

Embodiment 2

[0060] 4000 tons / year of trichlorosilane refining, the feed composition is as follows: chlorosilane mixture feed composition: trichlorosilane 95wt%, dichlorodihydrosilane 2.5wt%, silicon tetrachloride 2.5wt%.

[0061]The feed flow rate is 4 tons / hour, the reflux flow / feed amount is 7, the tower top temperature is 52.7°C, the tower top pressure is 300kpa, and the pressure drop across the tower is 10kpa.

[0062] There are a total of 110 theoretical trays in the partitioned rectification column, of which there are 30 theoretical trays in the public rectification section, 30 theoretical trays in the common stripping section, and 50 theoretical trays in the partition section. At the 55th theoretical plate, the discharge position is located at the 54th theoretical plate. The liquid phase flow ratio on both sides of the partition is 1:1.33, which can be realized by setting the flow controller outside the tower by the method of the above example, and the trichlorosilane can be refine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com