Laser processing device and method

A technology of laser processing and laser beam, which is applied in the direction of additive processing, additive manufacturing, process efficiency improvement, etc., can solve the problems of not having rich and diverse color metal materials to choose from, cracking, etc., and achieve shortened coloring cycle and high strength , The effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0049] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

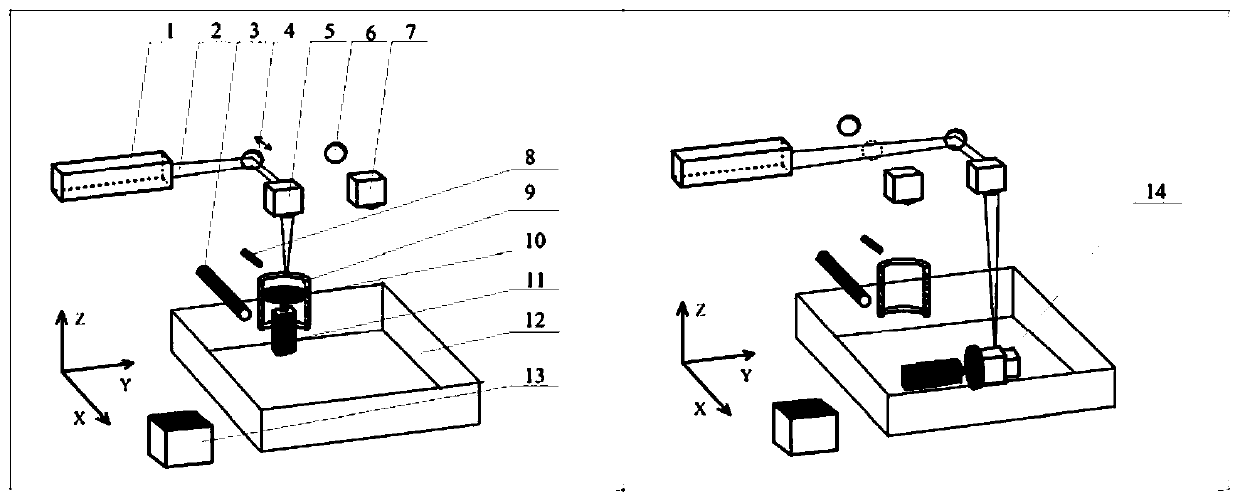

[0050] The invention is a laser processing device and method. The invention is aimed at selective laser sintering of metal materials. The metal powder is sprayed into the powder chamber through the powder nozzle, and the compaction and uniform distribution of the powder in the powder chamber are realized by the reciprocating horizontal rolling of the pressing roller. ;The laser beam is reflected by the movable 45° mirror to the two-dimensional scanning galvanometer, and the laser beam output by the two-dimensional scanning galvanometer scans the section track of the 3D printing model layered and sliced by the main control device to complete the selection of the single layer The permanent laser sintering work accumulates layer by layer until the final complete print is obtained; the main control device controls the scanning of the thr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com