Radish dicing machine

A technology of dicing machine and radish, applied in metal processing and other directions, can solve the problems of affecting work, slow dicing speed, low work efficiency, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

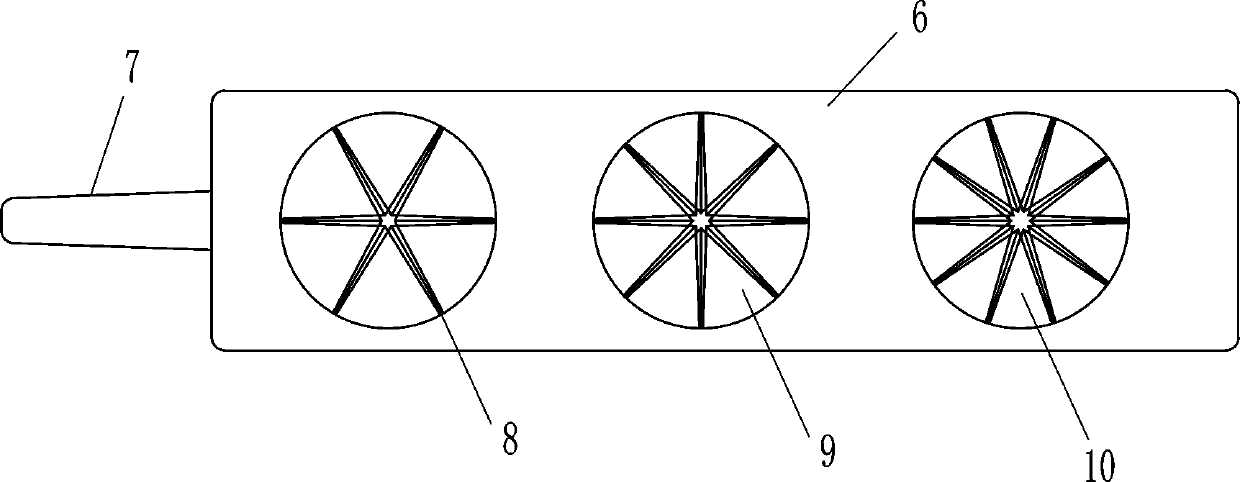

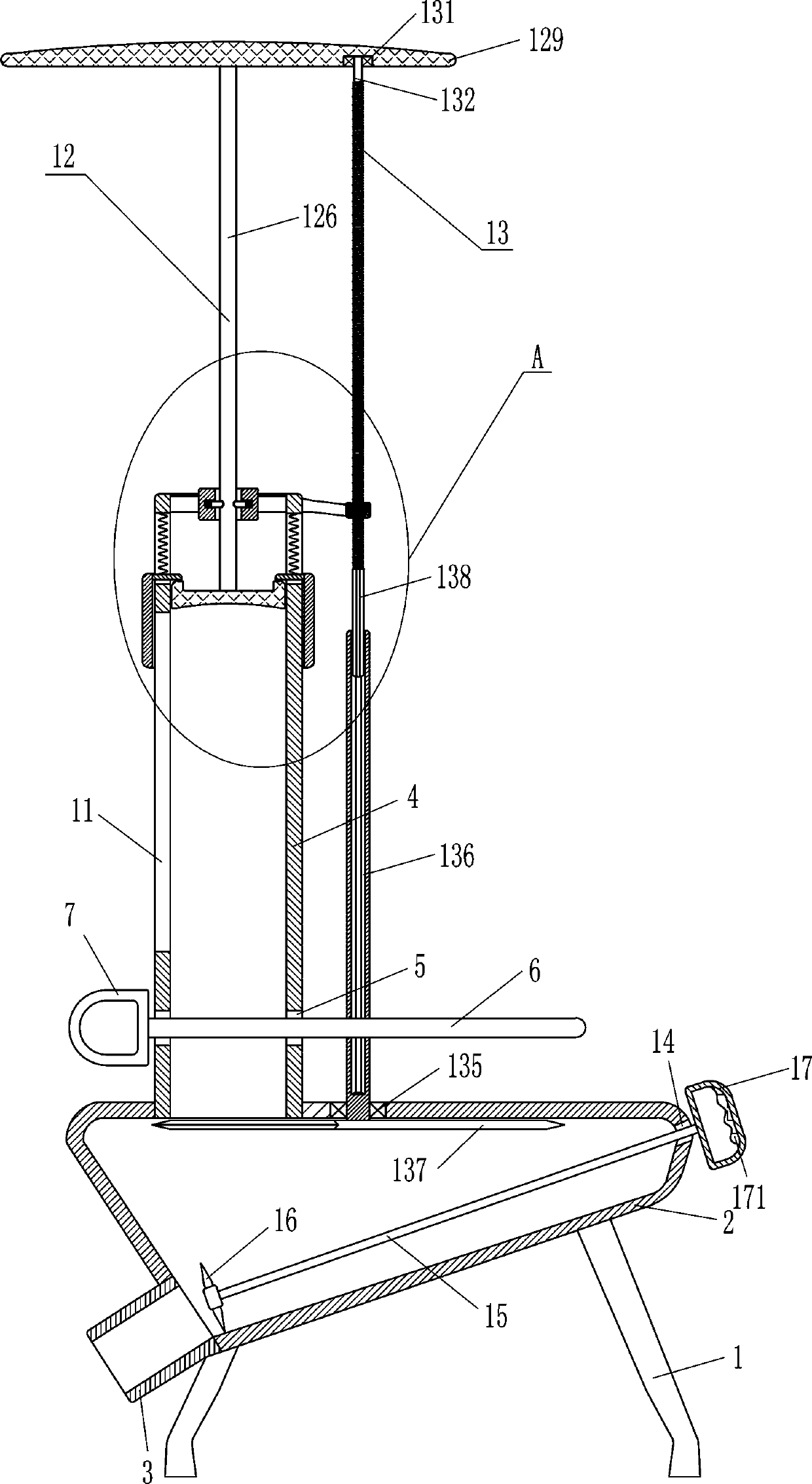

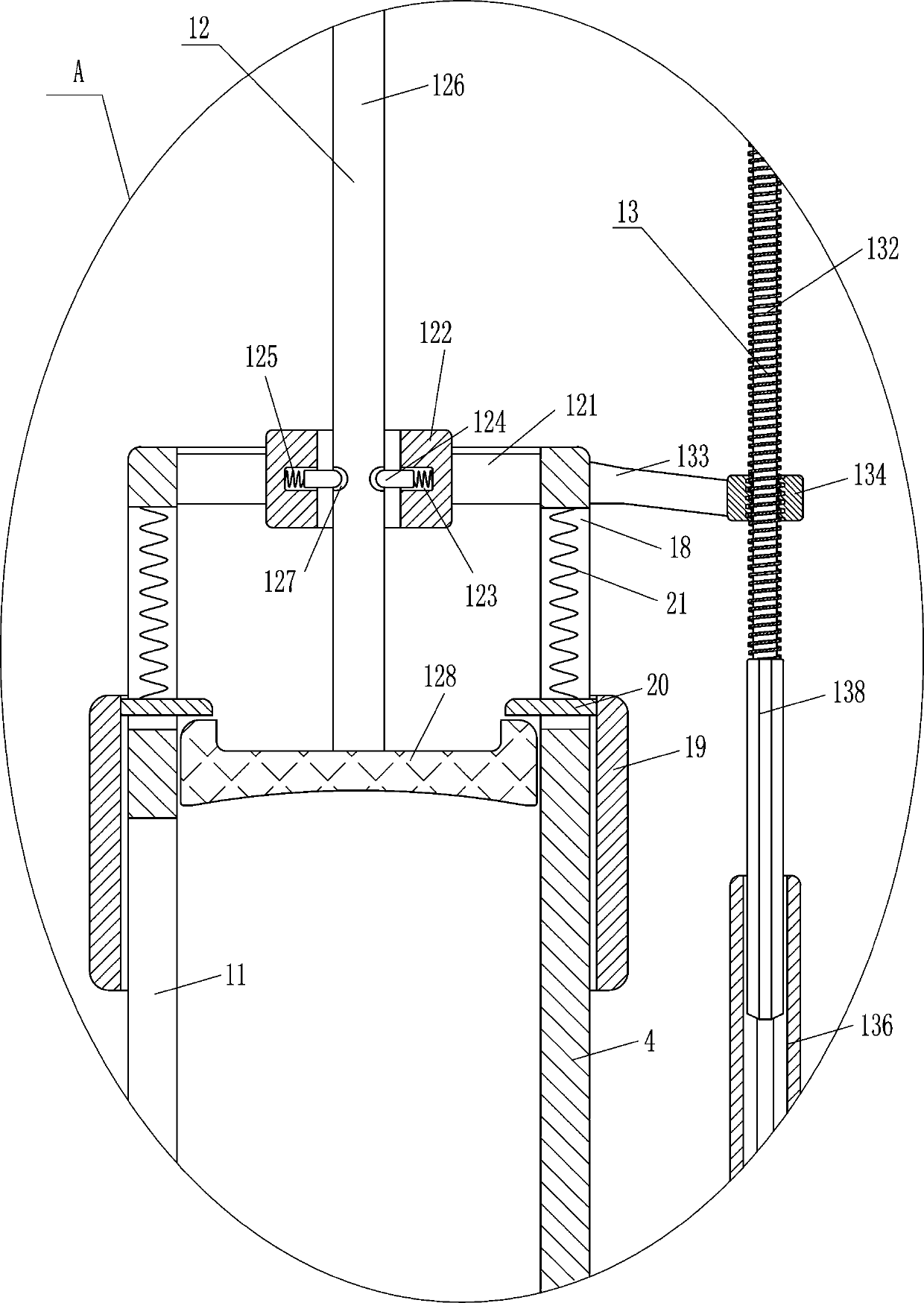

[0016] A radish dicer such as Figure 1-3 As shown, it includes a leg 1, a blanking frame 2, a discharge pipe 3, a round pipe 4, a movable plate 6, a first handle 7, a first blade 8, a second blade 9, a third blade 10 and a driving device 12 , the left and right sides of the outer bottom of the blanking frame 2 are provided with outriggers 1, the blanking frame 2 is connected with the outriggers 1 by means of bolts, the lower part of the left side of the blanking frame 2 is provided with a discharge pipe 3, and the discharge pipe 3 It communicates with the blanking frame 2, the left side of the top of the blanking frame 2 is provided with a circular tube 4, the circular tube 4 communicates with the blanking frame 2, the first opening 5 is opened on the left and right sides of the lower part of the circular tube 4, and the left and right sides A movable plate 6 is arranged between the first openings 5, and the left end of the movable plate 6 is connected with a first handle 7. ...

Embodiment 2

[0018] A radish dicer such as Figure 1-3 As shown, it includes a leg 1, a blanking frame 2, a discharge pipe 3, a round pipe 4, a movable plate 6, a first handle 7, a first blade 8, a second blade 9, a third blade 10 and a driving device 12 , the left and right sides of the outer bottom of the blanking frame 2 are provided with outriggers 1, the lower part of the left side of the blanking frame 2 is provided with a discharge pipe 3, the discharge pipe 3 communicates with the inside of the blanking frame 2, and the left side of the top of the blanking frame 2 A round pipe 4 is provided, and the round pipe 4 communicates with the blanking frame 2. First openings 5 are arranged on the left and right sides of the bottom of the round pipe 4. A movable plate 6 is arranged between the first openings 5 on the left and right sides. The movable plate 6 The left end is connected with a first handle 7, and the movable plate 6 is provided with a first blade 8, a second blade 9 and a t...

Embodiment 3

[0021] A radish dicer such as Figure 1-3 As shown, it includes a leg 1, a blanking frame 2, a discharge pipe 3, a round pipe 4, a movable plate 6, a first handle 7, a first blade 8, a second blade 9, a third blade 10 and a driving device 12 , the left and right sides of the outer bottom of the blanking frame 2 are provided with outriggers 1, the lower part of the left side of the blanking frame 2 is provided with a discharge pipe 3, the discharge pipe 3 communicates with the inside of the blanking frame 2, and the left side of the top of the blanking frame 2 A round pipe 4 is provided, and the round pipe 4 communicates with the blanking frame 2. First openings 5 are arranged on the left and right sides of the bottom of the round pipe 4. A movable plate 6 is arranged between the first openings 5 on the left and right sides. The movable plate 6 The left end is connected with a first handle 7, and the movable plate 6 is provided with a first blade 8, a second blade 9 and a t...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap