LCD glass inserting frame machine

A rack-inserting and glass technology, which is applied to conveyor objects, furnaces, lighting and heating equipment, etc., can solve the problems of low insertion efficiency, damage to LCD glass, and high labor costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

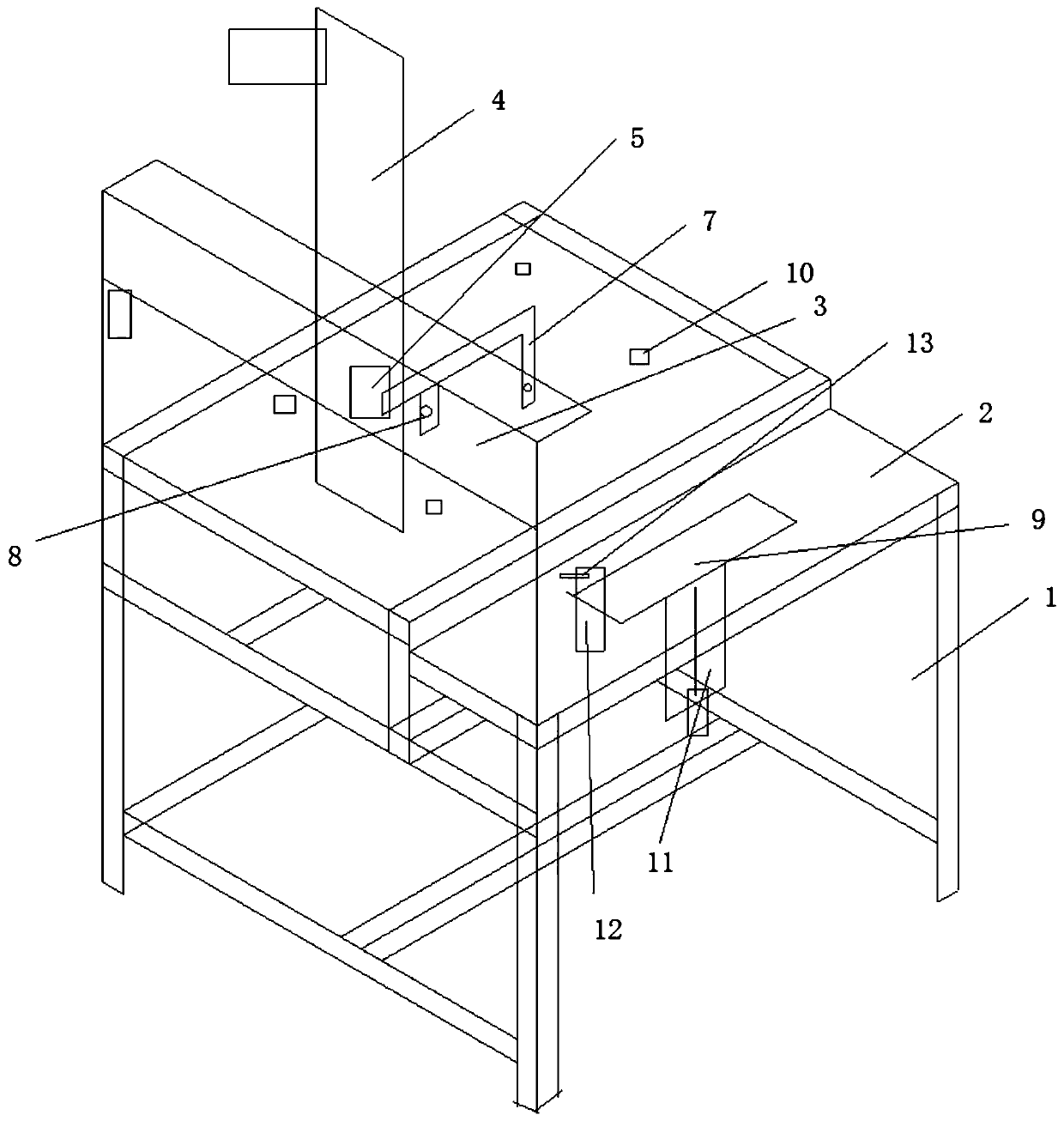

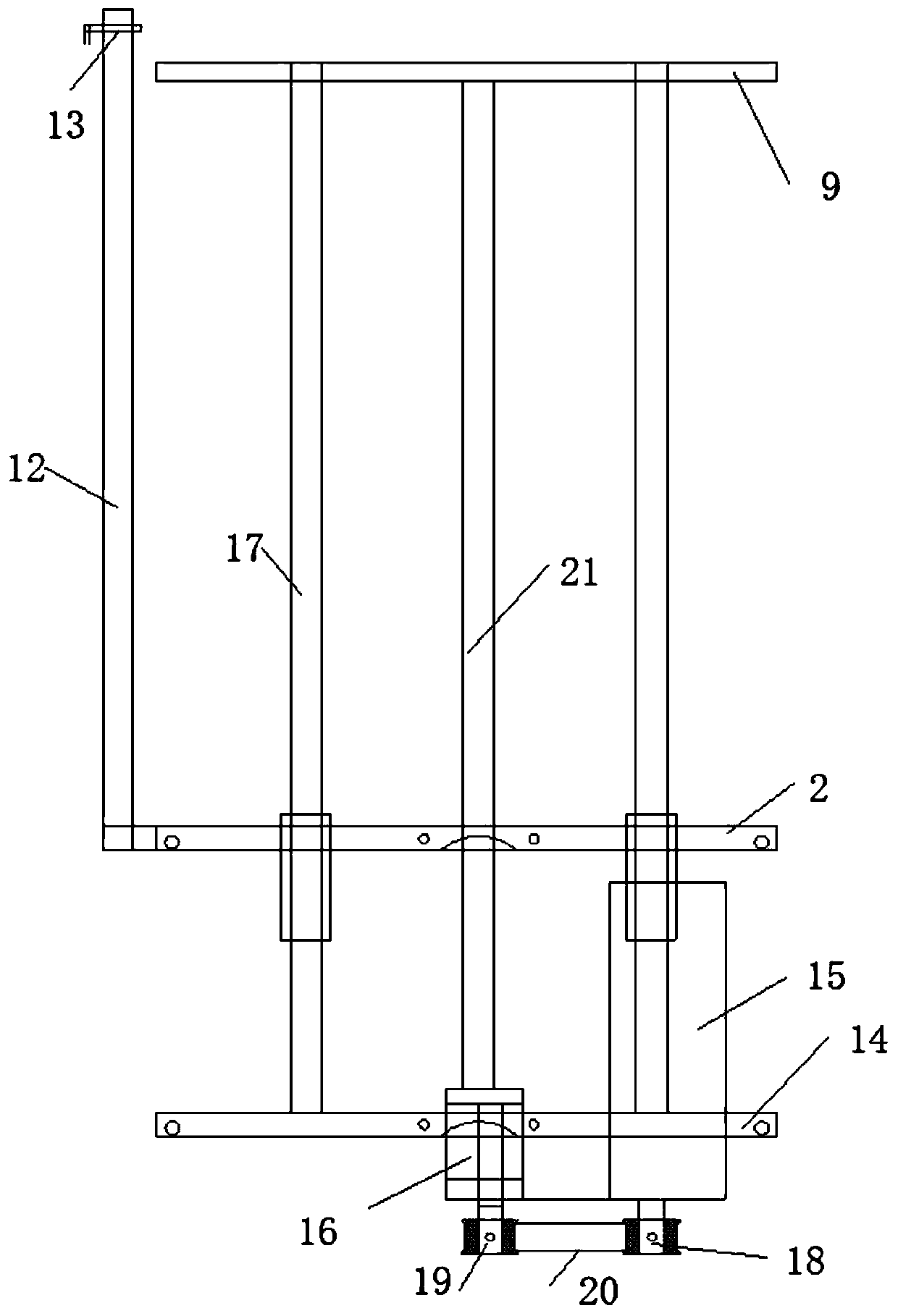

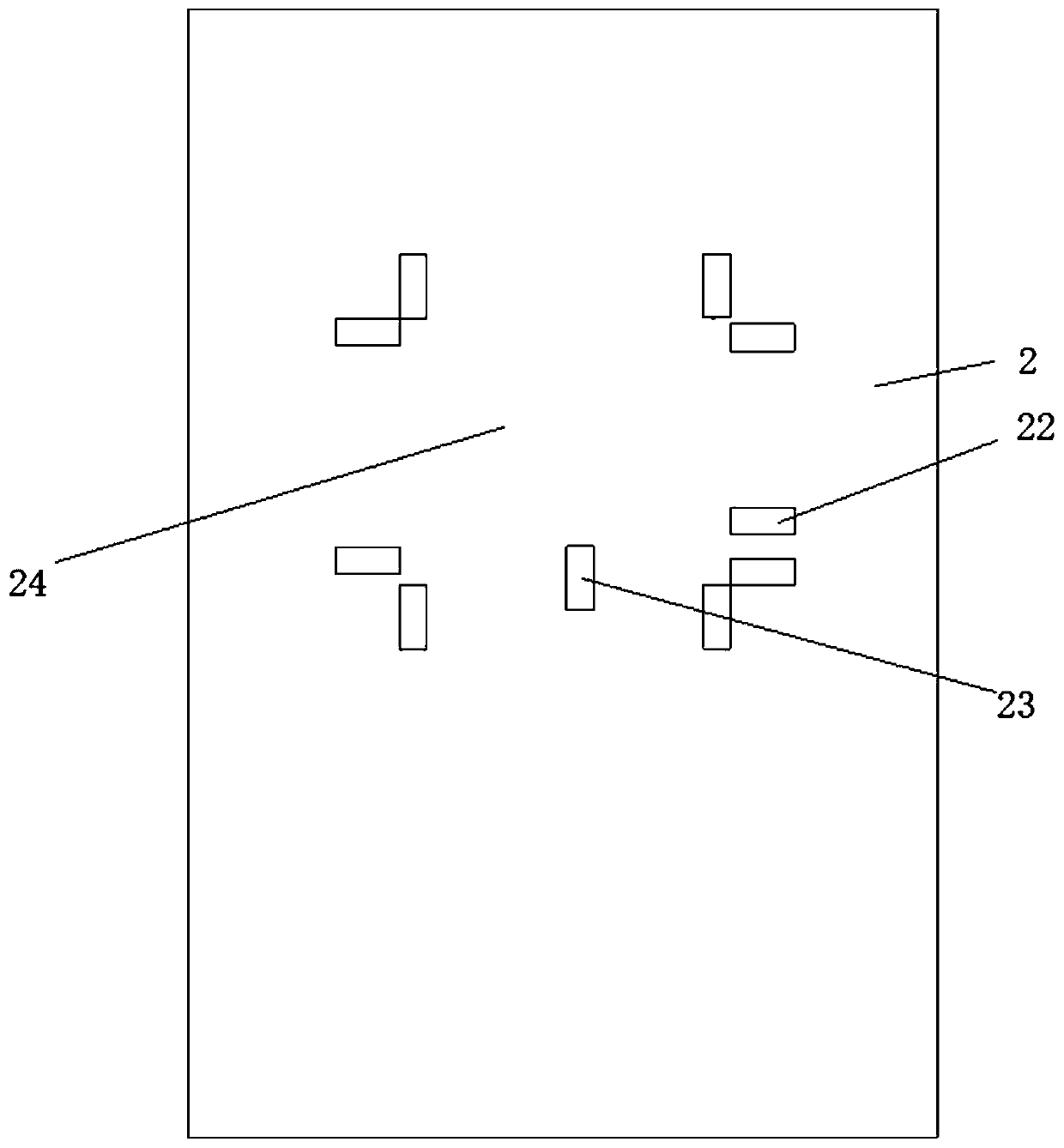

[0020] Examples such as Figure 1 to Figure 6 The shown LCD glass racking machine includes a bracket 1, a workbench 2 arranged on the bracket 1, a horizontal guide rail mechanism 3 is arranged on the top of the workbench 2, and a horizontal guide rail mechanism 3 is mounted on which can slide horizontally along it. The longitudinal guide rail mechanism 4 is provided with a fixed block 5 that can slide up and down along it, the fixed block 5 is provided with a turning cylinder 6, and the turning cylinder 6 is provided with a fixed frame 7 that can be turned over with it; the turning cylinder 6 is used to drive the fixed frame 7 to realize the turning over of the horizontal state and the vertical state; the fixed frame 7 is set horizontally when it is in normal state, and a group of suction cups 8 are arranged on its back side, and the suction cups 8 are connected to the air pipe; when the fixed frame 7 is turned over, the LCD glass is inserted into the When the LCD basket is 25...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com