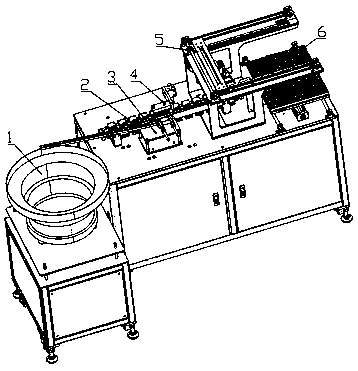

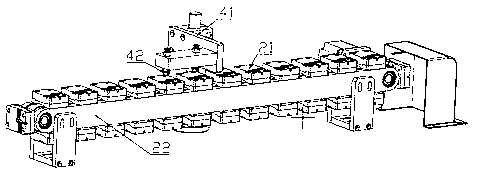

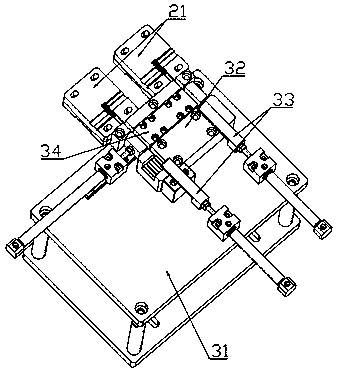

A graphite rod torsion spring automatic assembly machine

A graphite rod and assembly machine technology, which is applied in the field of automation, can solve the problems of broken graphite rods, waste of resources and defective products, low efficiency of manual assembly, etc., and achieves the effect of improving the qualification rate, saving labor, and realizing automatic handling and transfer.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] It should be noted that the above-mentioned technical features continue to be combined with each other to form various embodiments not listed above, which are all regarded as the scope of the description of the present invention; and, for those of ordinary skill in the art, improvements can be made according to the above description Or transformation, and all these improvements and transformations should belong to the protection scope of the appended claims of the present invention.

[0023] In order to facilitate the understanding of the present invention, the present invention will be described in more detail below in conjunction with the accompanying drawings and specific embodiments. Preferred embodiments of the invention are shown in the accompanying drawings. However, the present invention can be implemented in many different forms and is not limited to the embodiments described in this specification. On the contrary, these embodiments are provided to make the un...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com