Automatic cleaning instrument for filter screen

An automatic cleaning and filter technology, applied in the direction of filter regeneration, filter separation, chemical instruments and methods, etc., can solve the problem that the cleaning quality of the air conditioner filter will not have a stable cleaning effect guarantee, the physical strength and mental state of the cleaning workers are limited, Increased subway operating costs and other issues to achieve the effects of reducing noise or a small amount of leakage, low cost, and reduced volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

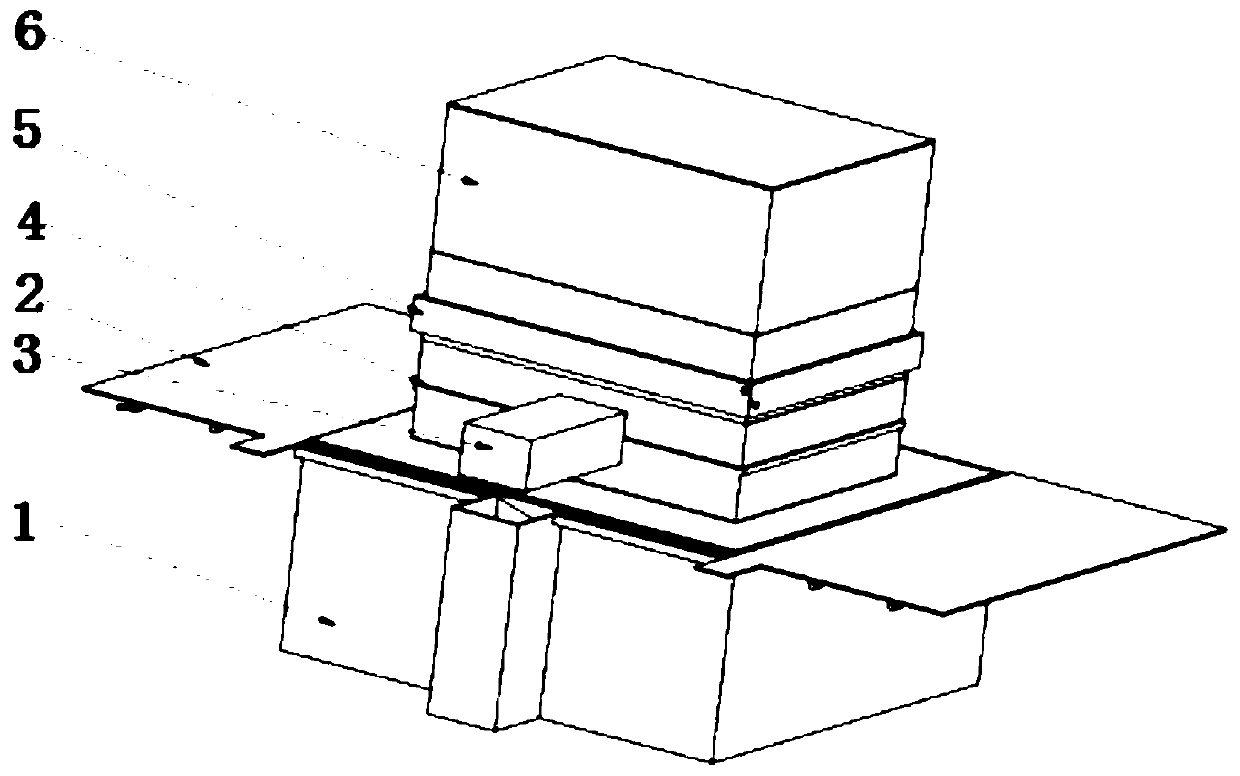

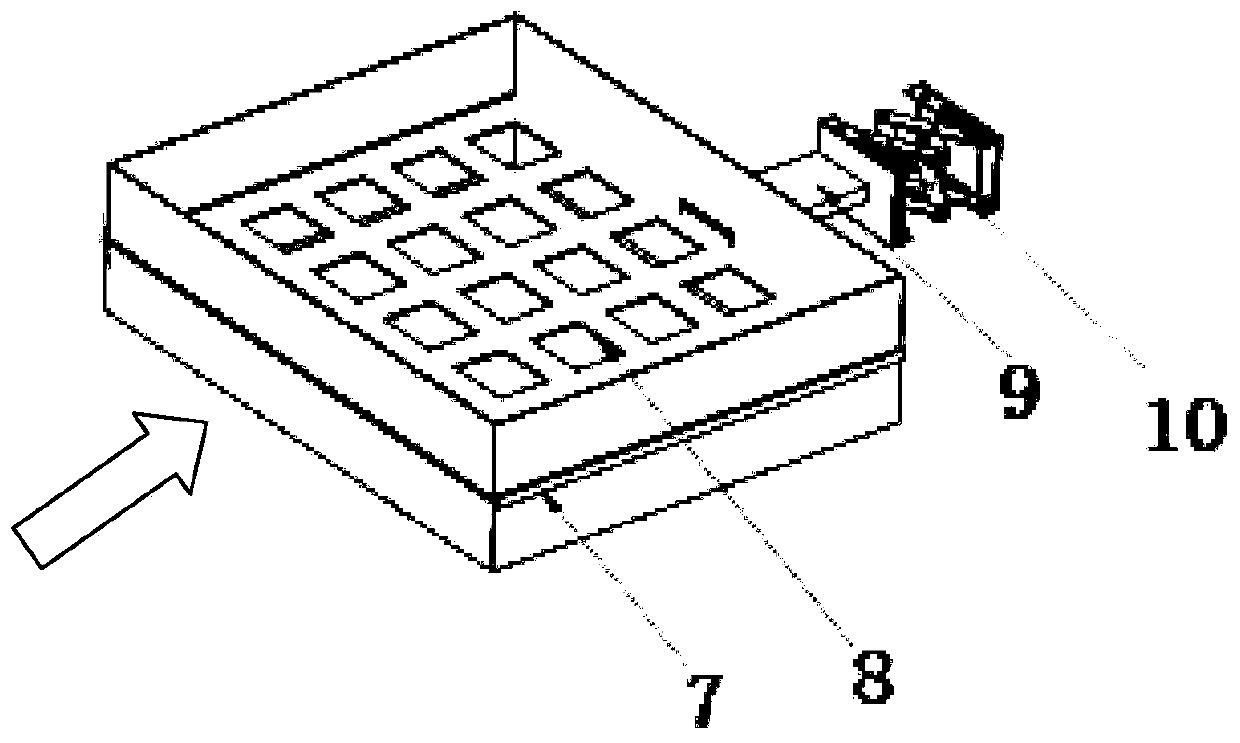

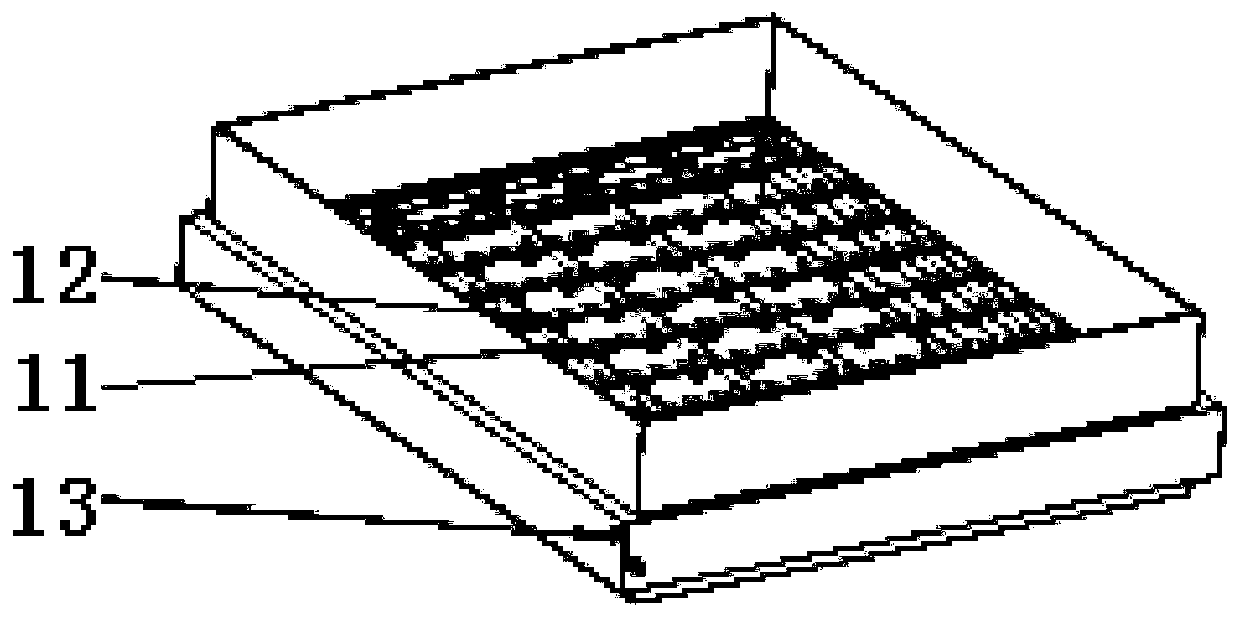

[0037] This embodiment provides a filter screen automatic cleaning instrument, such as figure 1 As shown, it includes a controller, a box body 1 and a cleaning assembly placed inside the box body 1 during cleaning. The cleaning assembly includes a lifting recovery layer, a workpiece placement layer 4, The cleaning layer 5 and the drying layer 6, when working, the recovery layer is lifted to place the cleaning components inside the box body 1, the filter screen 8 is inserted into the workpiece placement layer 4, and the cleaning layer 5 cleans the filter screen 8. After cleaning, the drying layer 6 Remove the residual water in the filter screen 8, lift the recovery layer to collect waste liquid and make the workpiece placement layer 4, cleaning layer 5 and drying layer 6 protrude from the box body 1; the box body 1 is equipped with a sliding cover plate 2, and the controller controls the sliding cover plate 2 It is closed when it is working, and it is opened after the work is c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com