A method for preparing 3-bromo-4-methanesulfonylpyridine

A technology of methanesulfonylpyridine and dibromopyridine, which is applied in the field of preparation of 3-bromo-4-methanesulfonylpyridine, can solve the problem of low yield of 3-bromo-4-methanesulfonylpyridine, cumbersome operation, not simple, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

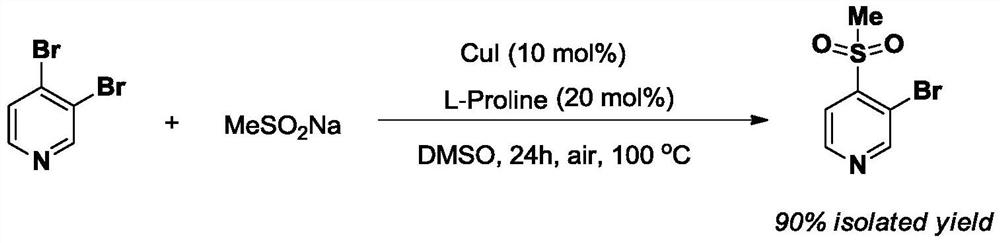

[0013] Dimethyl sulfoxide (4.0 mL), 3,4-dibromopyridine (5 mmol, 1.185 g), sodium methanesulfinate (6 mmol, 0.613 g), and iodide iodide were successively added to a 50 mL pressure-resistant tube. (0.5 mmol, 0.095 g), L-proline (1.0 mmol, 0.115 g), the inverse temperature was controlled at 100 degrees Celsius, and the reaction was vigorously stirred for 24 hours. After the reaction was completed, it was cooled to room temperature, and the reaction solution was concentrated and separated by column chromatography in sequence to obtain the target product 3-bromo-4-methanesulfonylpyridine (1.06 g, 90%).

[0014] The equation involved in the reaction is as follows:

[0015]

[0016] The NMR data and mass spectrometry data of the target product 3-bromo-4-methanesulfonylpyridine are as follows:

[0017] 1 H NMR (300MHz, CDCl 3 )δ8.90(s, 1H), 8.75(d, J=5.0Hz, 1H), 7.95(d, J=4.8Hz, 1H), 3.23(s, 3H).

[0018] 13 C NMR (75MHz, CDCl 3 )δ154.59,149.92,147.00,123.58,117.65,42.03.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com