Material for fireproof sealing of cable entry

A cable entry, fire-proof and flame-retardant technology, which is applied in the direction of fire-proof paint, conductive paint, coating, etc., can solve the problems of damaged components in the box, lack of density, flow collapse, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

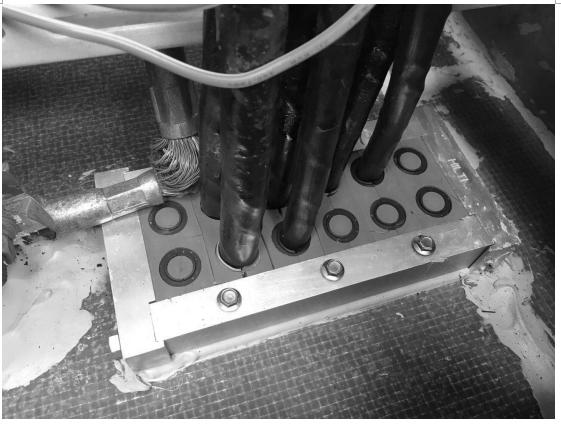

Image

Examples

Embodiment 1

[0017] A material suitable for fire-proof and flame-retardant sealing of cable inlets in substations. The raw materials include: by weight, 100 parts of ethylene-vinyl acetate copolymer (EVA), 20 parts of maleic anhydride grafted polypropylene, tung oil 30 parts, 10 parts of graphene nanofiber, 6 parts of azodicarbonamide (AC), 14 parts of antimony trioxide, 6 parts of dibenzoyl peroxide, 9 parts of stearic acid, 8 parts of octyl epoxy soybean oleate share.

[0018] The specific preparation method is as follows: adding graphene nanofibers into concentrated sulfuric acid and stirring at 60°C for 1 to 3 hours to obtain acidified graphene nanofibers; grafting EVA, maleic anhydride to polypropylene, tung oil, and acidifying Graphene nanofibers, epoxy octyl soybean oleate, and stearic acid were added to an internal mixer and banburyed at 100°C for 10 minutes. After mixing evenly, azodicarbonamide, antimony trioxide and diperoxide were added. Benzoyl, after banburying for 5 minutes...

Embodiment 2

[0020] A material suitable for fire-proof and flame-retardant plugging of cable inlets in substations. The raw materials include: 110 parts by weight of ethylene-vinyl acetate copolymer (EVA), 40 parts of maleic anhydride grafted polypropylene, tung oil 40 parts, 15 parts of graphene nanofiber, 6 parts of azodicarbonamide (AC), 13 parts of antimony trioxide, 5 parts of dibenzoyl peroxide, 10 parts of stearic acid, 10 parts of epoxy octyl soybean oleate share.

[0021] The specific preparation method is as follows: adding graphene nanofibers into concentrated sulfuric acid and stirring at 60°C for 1 to 3 hours to obtain acidified graphene nanofibers; grafting EVA, maleic anhydride to polypropylene, tung oil, and acidifying Graphene nanofibers, epoxy octyl soybean oleate, and stearic acid were added to an internal mixer and banburyed at 100°C for 10 minutes. After mixing evenly, azodicarbonamide, antimony trioxide and diperoxide were added. Benzoyl, after banburying for 5 minut...

Embodiment 3

[0023] A material suitable for fire-proof and flame-retardant plugging of cable inlets in substations. The raw materials include: by weight, 120 parts of ethylene-vinyl acetate copolymer (EVA), 50 parts of maleic anhydride grafted polypropylene, tung oil 50 parts, 15 parts of graphene nanofiber, 10 parts of azodicarbonamide (AC), 20 parts of antimony trioxide, 9 parts of dibenzoyl peroxide, 10 parts of stearic acid, 10 parts of epoxy octyl soybean oil share.

[0024] The specific preparation method is as follows: adding graphene nanofibers into concentrated sulfuric acid and stirring at 60°C for 1 to 3 hours to obtain acidified graphene nanofibers; grafting EVA, maleic anhydride to polypropylene, tung oil, and acidifying Graphene nanofibers, epoxy octyl soybean oleate, and stearic acid were added to an internal mixer and banburyed at 150°C for 10 minutes. After mixing evenly, azodicarbonamide, antimony trioxide and diperoxide were added. Benzoyl, after banburying for 5 minute...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com