Road construction method

A technology for road construction and roadbed, applied in the direction of roads, roads, road repair, etc., can solve the problems of mechanical and artificial slack work, high technical requirements of mechanical operators, and achieve the improvement of work efficiency, construction quality, and strong anti-interference ability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] Embodiment 1, a road construction method, specifically, comprises the following steps:

[0037] Step 1: Level the area to be constructed, form a horizontal roadbed, and dig drainage ditches at the same time;

[0038] Step 2, laying a cushion on the roadbed, the cushion adopts a sand cushion, including 48% crushed stone, 30% slag and 22% lime soil, the particle size of the crushed stone is 4-18mm, and the particle size of the slag 2-8mm, cushion thickness 8-12cm;

[0039] Step 3, laying an asphalt layer on the cushion layer, and compacting it while it is hot with a road roller. The amount of asphalt laid is 2kg / ㎡, and the temperature of the asphalt is controlled to be 110-150°C when compacted by a road roller;

[0040] Step 4: Lay a layer of molten emulsified asphalt on the asphalt layer, and lay an asphalt mixture pavement layer on the emulsified asphalt. The amount of emulsified asphalt laid is 3Kg / ㎡, and compacted while it is hot. Fill water-stop materials at the jo...

Embodiment 2

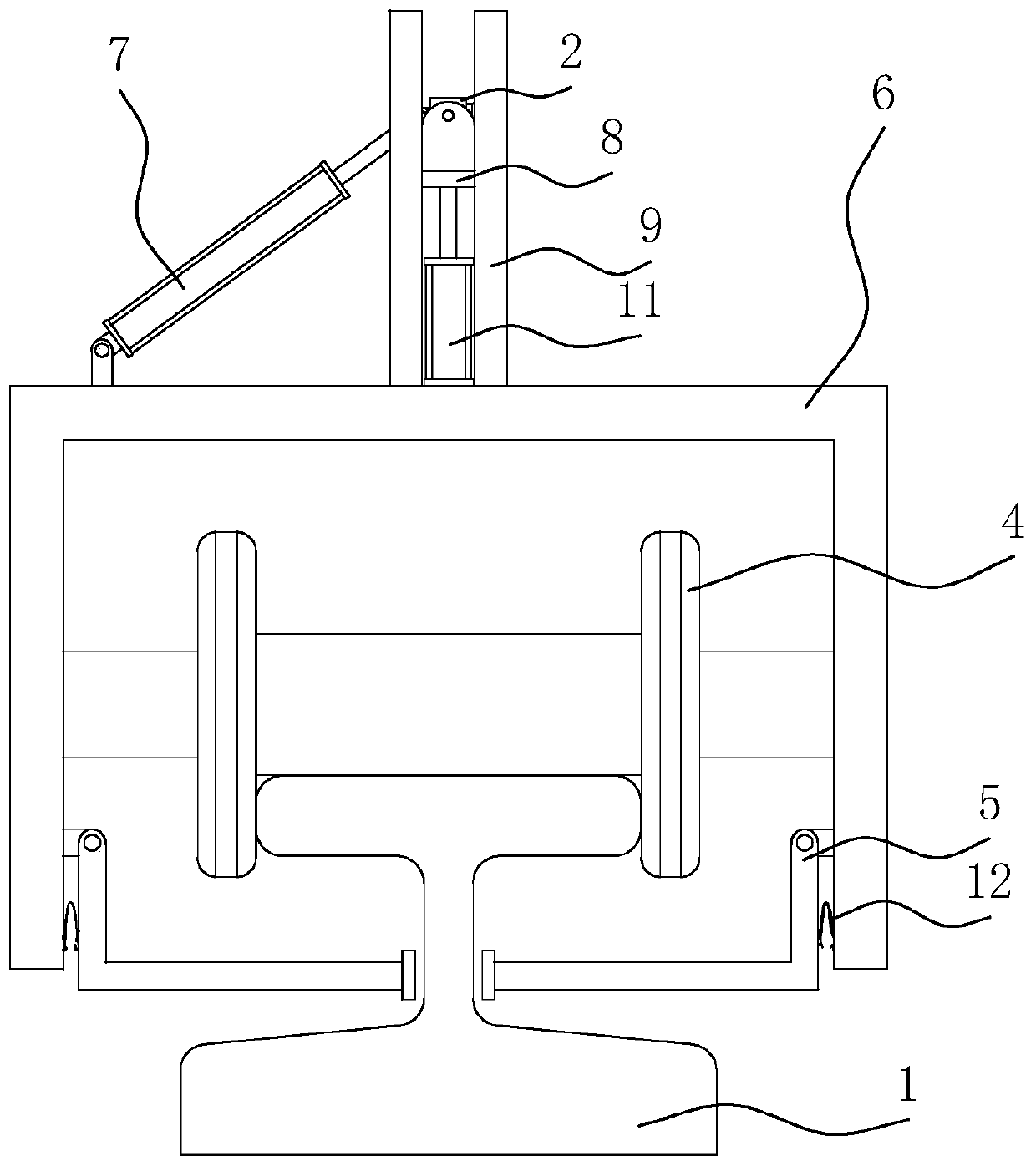

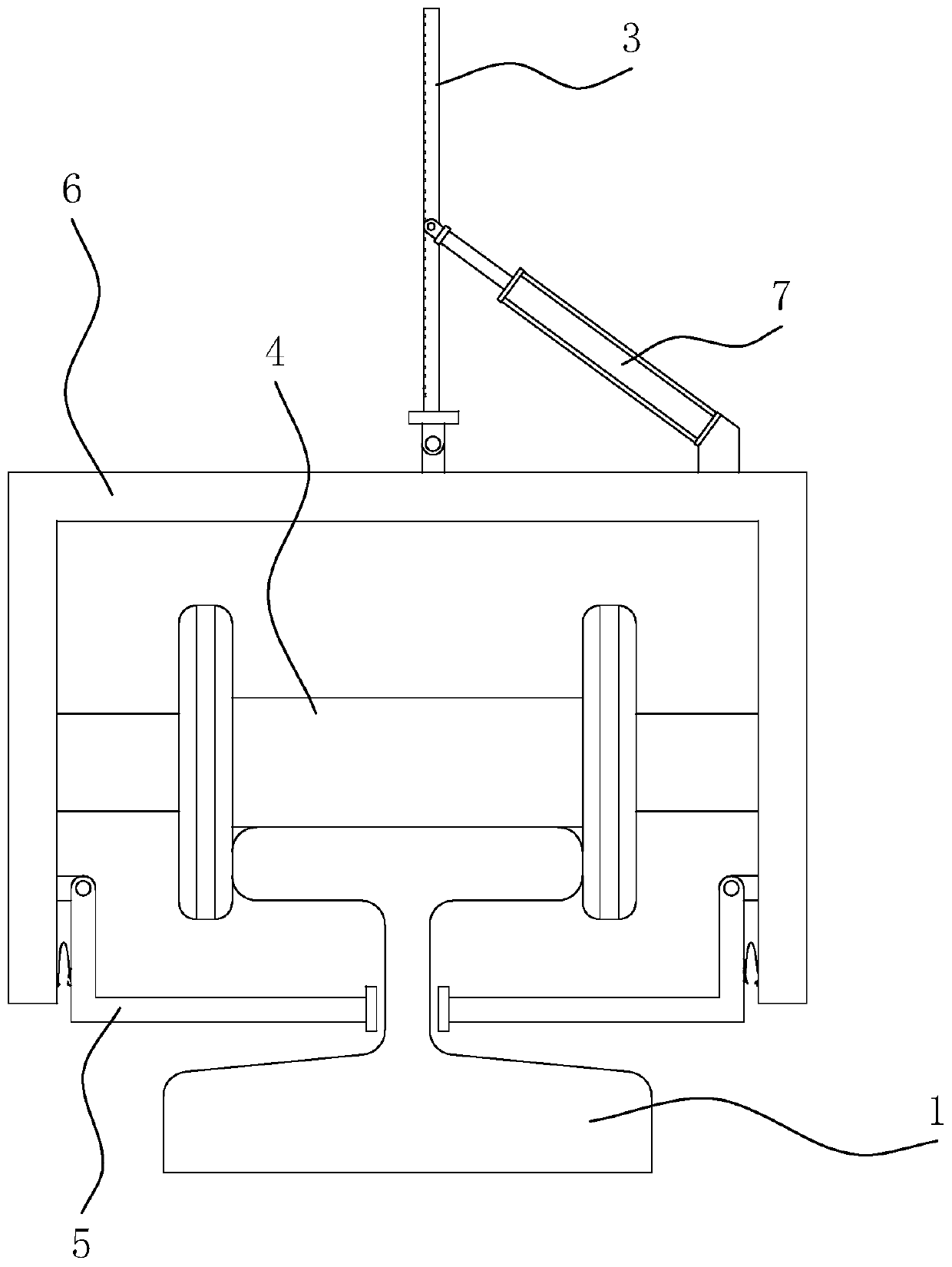

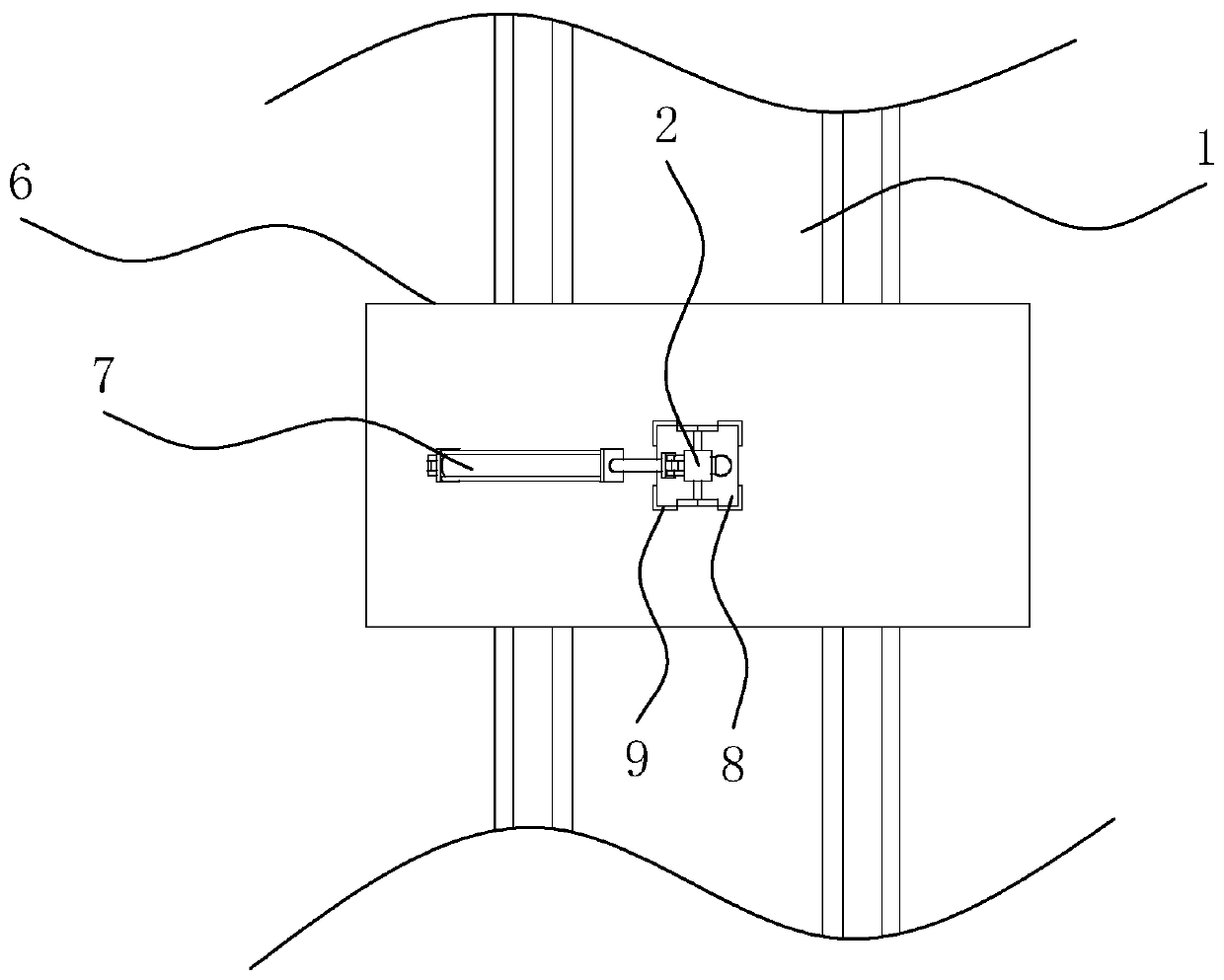

[0052] Embodiment 2, a kind of road construction method, the difference with embodiment 1 is, as figure 1 and 2 As shown, the adjusting member is a jacking cylinder 11 vertically fixed on the top surface of the mounting seat 6, and the top piston rod of the jacking cylinder 11 is fixedly connected to the bottom surface of the adjustment platform 8. Under the action, the height of the adjustment platform 8 can be controlled by controlling the stroke of the jacking cylinder 11 .

[0053] It should be noted that the leveling oil cylinder 7 and the jacking oil cylinder 11 used in the above embodiments can be replaced with other driving devices such as air cylinders and threaded screws according to actual production requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com