Water-permeable spur dike capable of adjusting angle with river bank

A river bank and angle technology, applied in the direction of pier, quay wall, embankment, etc., can solve the problems of large impact force of water flow, easy to be damaged, poor stability, etc., and achieve the effect of slowing down the flow velocity of water flow, ensuring survival rate and reducing impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

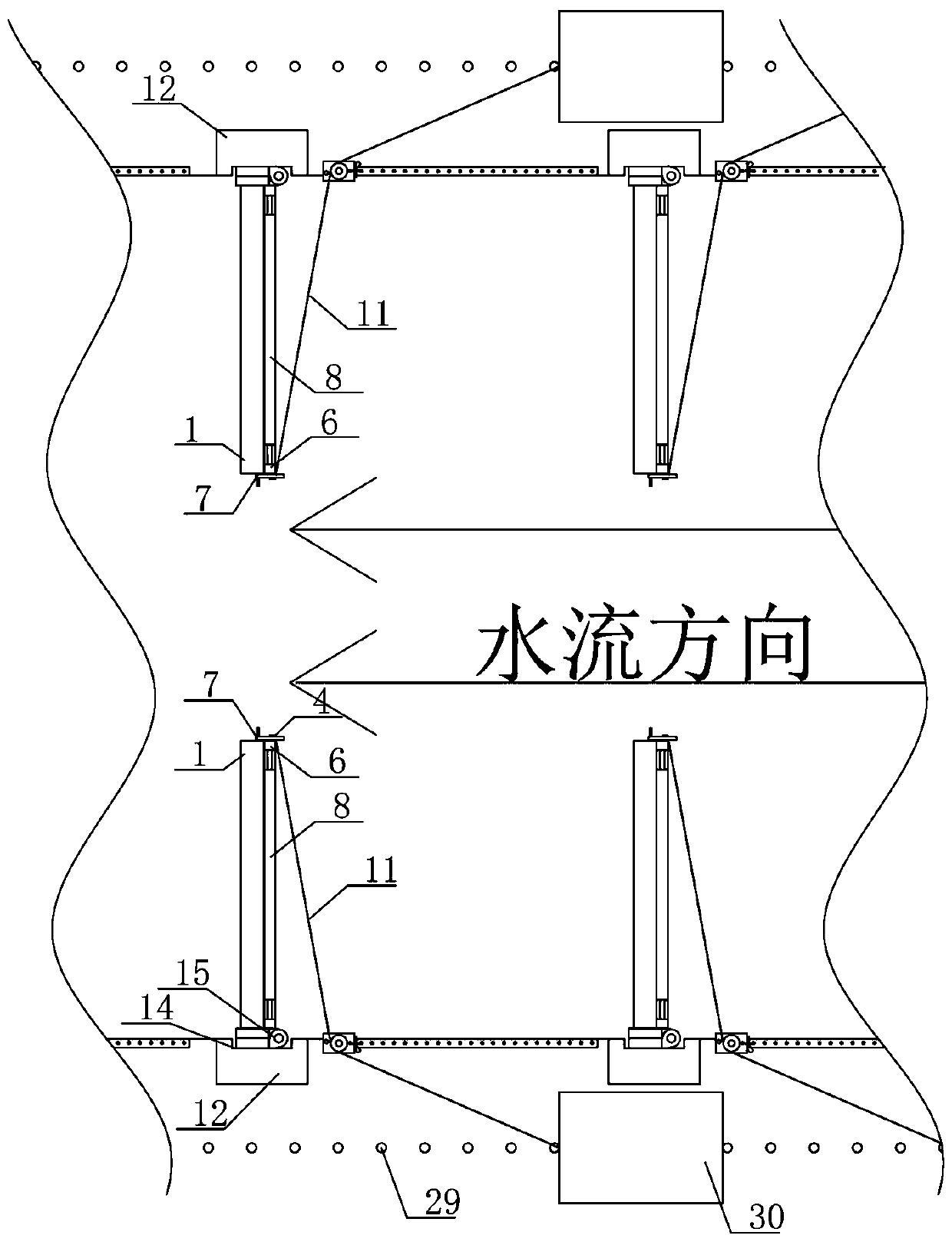

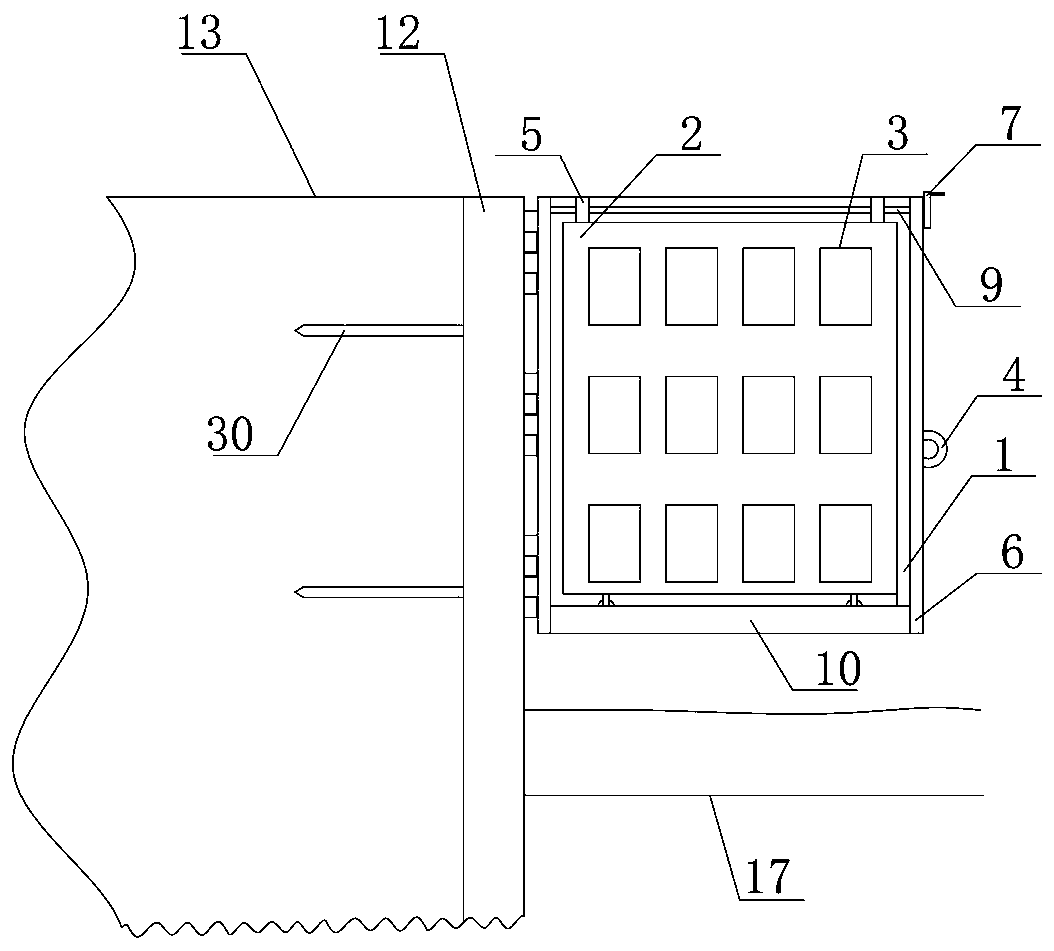

[0028] like figure 1 , figure 2 As shown, the permeable spur group is composed of multiple permeable spur dike intervals. The permeable spur dike includes steel sheet piles 12 vertically arranged on one side of the river. Two fixed horizontal columns 24 are provided, and the fixed horizontal columns 24 are fixed in the embankment. A groove 14 is vertically opened in the middle of the front side of the upper section of the steel sheet pile 12, and a cuboid is vertically arranged in the river channel on the front side of the groove 14. The shape of the dam body has a plurality of rectangular water passage holes on the dam body.

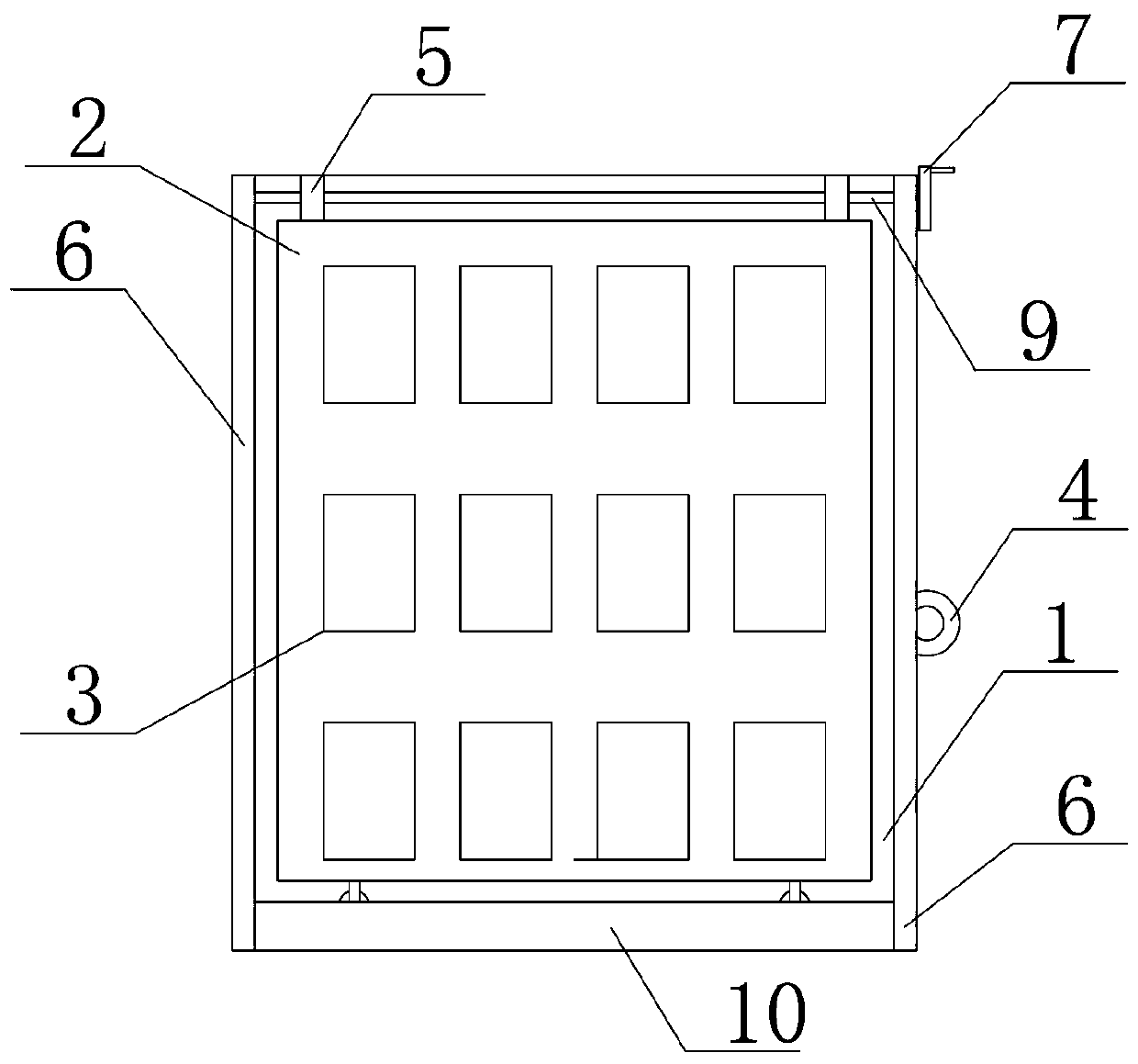

[0029] like image 3 As shown, the dam body includes a main dam body 1 and an auxiliary dam body 2 arranged on the water-facing surface in front of the main dam body. Both the main dam body 1 and the auxiliary dam body 2 have a plurality of rectangular water passage holes evenly corresponding to each other. The left and right ends of the front of th...

Embodiment 2

[0039] The difference between embodiment 2 and embodiment 1 is that the structure of the traction mechanism is different.

[0040] like Figure 8 , Figure 9 As shown, the river bank 13 is provided with a tractor 30, and the moving track of the tractor 30 is parallel to the river bank. Along the moving track line 26 of the tractor 30, a plurality of fixed pile grooves 29 are evenly opened on the river bank 13. The fixed piles installed in the adjacent fixed pile grooves 29 at both ends are used to limit the position of the tractor 30 .

[0041] like Figure 8 As shown, on the edge of the river bank, a fixed track 22 is arranged parallel to the river, and the bottom of the fixed track 22 is uniformly provided with a plurality of safety holes 23 along the direction of the track. The fixed track 22 is provided with a guide platform 16, and the bottom of the guide platform 16 It is fixed in the fixed track 22 and can move back and forth along the fixed track 22. The rear end of...

Embodiment 3

[0047] The difference between embodiment 3 and embodiment 2 lies in the structure of the dam body.

[0048] The water-facing surface of the dam body is covered with a bionic plant grass mat to reduce the impact of fish and other aquatic organisms on the dam body and effectively ensure the survival rate of aquatic organisms.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com