An external wall expansion joint structure and its installation method

A technology for expansion joints and exterior walls, which is applied to building components, building structures, buildings, etc., can solve problems such as poor waterproof performance and easy aging of waterstops, and achieve the effects of reducing humidity, accelerating aging, and improving waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

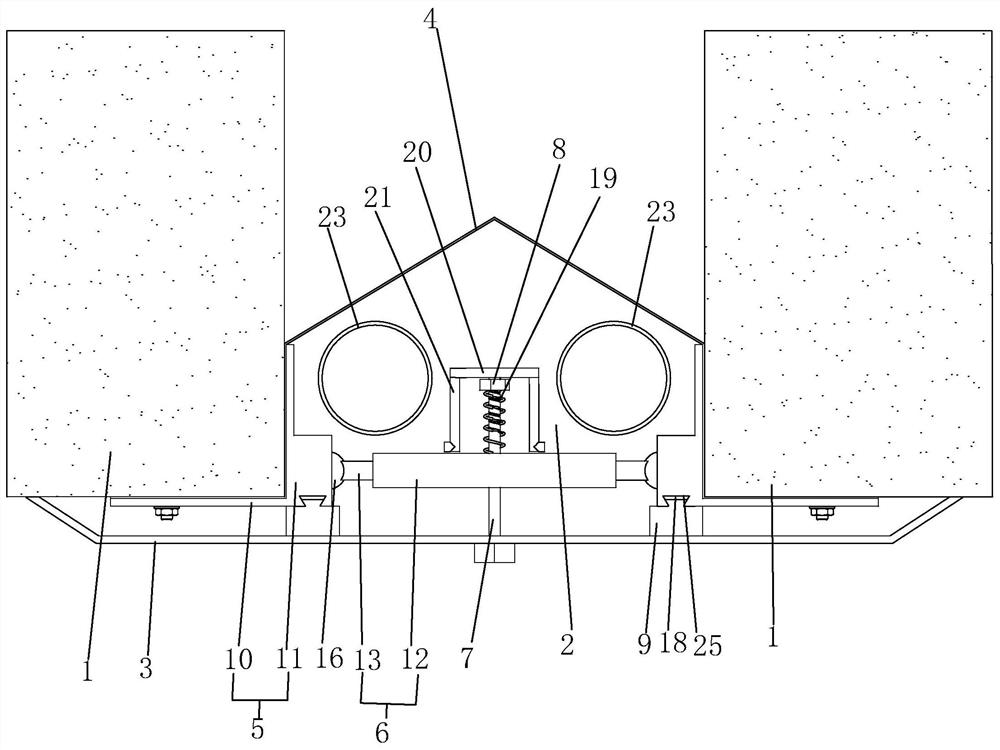

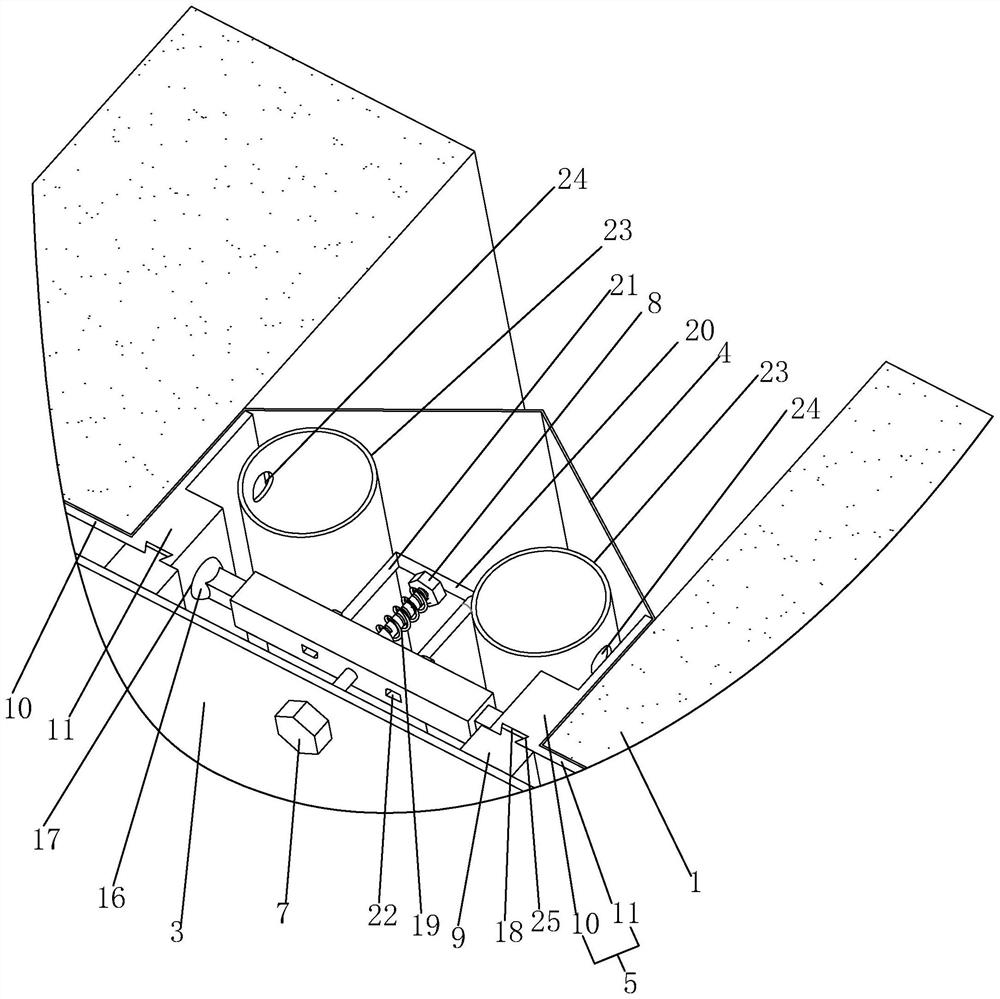

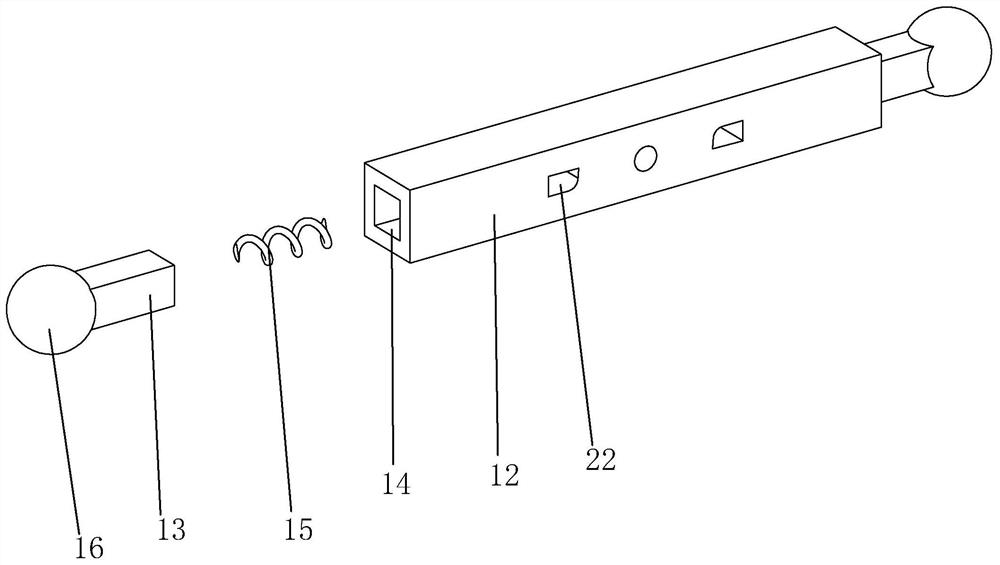

[0040] Embodiment 1: An external wall expansion joint structure, such as figure 1 and figure 2As shown, including the outer wall 1, the expansion joint 2, the cover plate 3 and the water stop belt 4, two bases 5 are arranged on the outer wall 1 on both sides of the expansion joint 2, and the two bases 5 are simultaneously connected by expansion bolts. Press and fix the two sides of the waterstop 4 on the outer wall 1 on both sides of the expansion joint 2 respectively. A number of sliding rods 6 are arranged at intervals along the vertical direction between the two bases 5 , and the cover plate 3 is closed on the expansion joint. 2, and both sides of the cover plate 3 are located at the outer wall 1 on both sides of the expansion joint 2, and the base 5 and the cover plate 3 are made of aluminum alloy. The cover plate 3 and the sliding rod 6 are fixed together by bolts 7 and nuts 8 , and waterproof rubber strips 9 are provided on both sides of the cover plate 3 and between t...

Embodiment 2

[0047] Embodiment 2: A method for installing an external wall expansion joint structure, comprising the following steps:

[0048] A. Clean the outer wall at the expansion joint to form the installation base;

[0049] B. Attach the waterstop to the installation base through the base glue;

[0050] C. Fix the two opposite bases on the outer walls on both sides of the expansion joint through expansion bolts;

[0051] D. Install the slide bar between the two bases, and place the cover plate, install the water-stop adhesive strip on the side wall of the base opposite the cover plate, and then fix the cover plate and the slide bar with bolts and nuts .

[0052] Double waterproofing is carried out through the water-stop strip and the water-stop rubber strip, thereby improving the waterproof performance of the expansion joint structure, and the installation of the expansion joint structure is facilitated through the above steps.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com