Multi-arm multi-drill drilling-loading-anchoring all-in-one machine with telescopic structure

A telescopic structure and integrated machine technology, applied in the installation of bolts, mechanically driven excavators/dredgers, earth drilling and mining, etc., can solve the inconvenient disassembly, downhole, underground transportation and assembly, drilling boom and excavation work The range of arm operation is not large, and the full-section operation cannot be realized, so as to achieve the effect of wide coverage, good working stability and small retraction size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

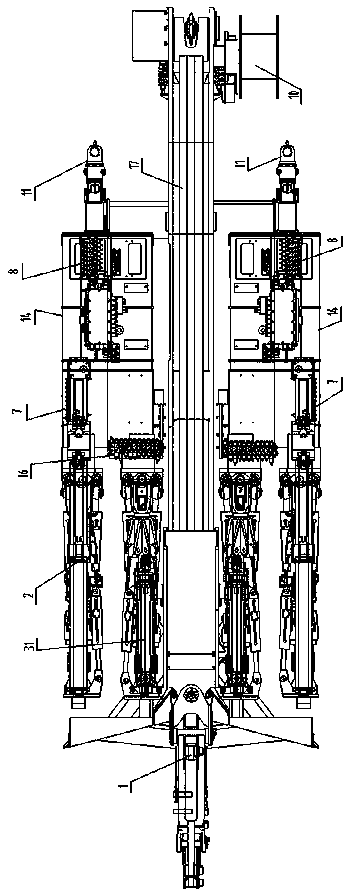

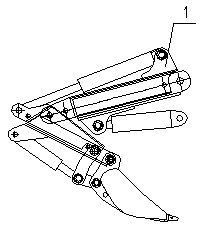

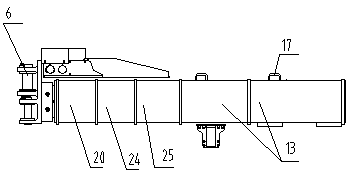

[0025] In the figure, a multi-arm, multi-drill, drill-installation and anchor integrated machine with a telescopic structure includes a vehicle frame 12, a conveying tank body 9, an excavating arm 1, a crawler walking mechanism 15, an electrical system and a hydraulic system, and the excavating arm There are front bolter 33 and rear bolter 11 respectively at the front and rear of one or both sides, and a drill arm mechanism is arranged at the lower end of the front bolter (by the working arm of excavation), and the conveying tank is located on the vehicle frame. In the middle position of the rear end, the lower (front) end of the conveying trough is a movable trough 22. The drill arm mechanism includes a drill arm head, and the drill arm head is arranged on the carriage propulsion beam 2, and the carriage propulsion beam is located at the excavation On both sides of the working arm, telescopic platforms are respectively arranged on the vehicle frame below the two sides of the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com