A small fully automatic multi-stage fast telescopic rod device

A telescopic rod, fully automatic technology, used in measuring devices, instruments, measuring instrument components, etc., can solve problems such as the impact of measurement accuracy, and achieve the effects of convenient operation, short recovery time, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments, where the schematic embodiments and descriptions of the present invention are used to explain the present invention, but not to limit the present invention.

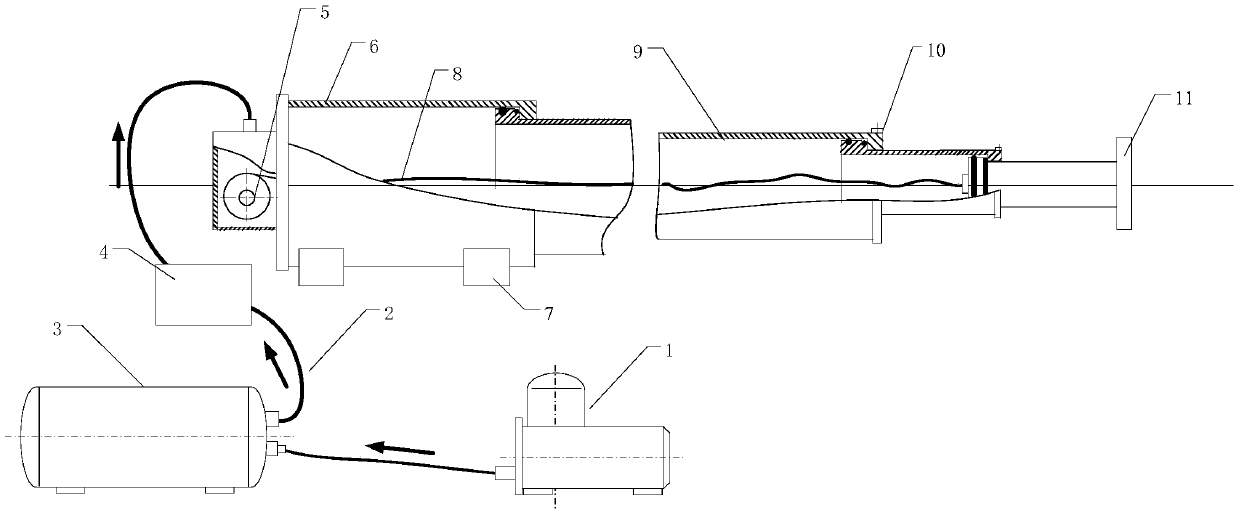

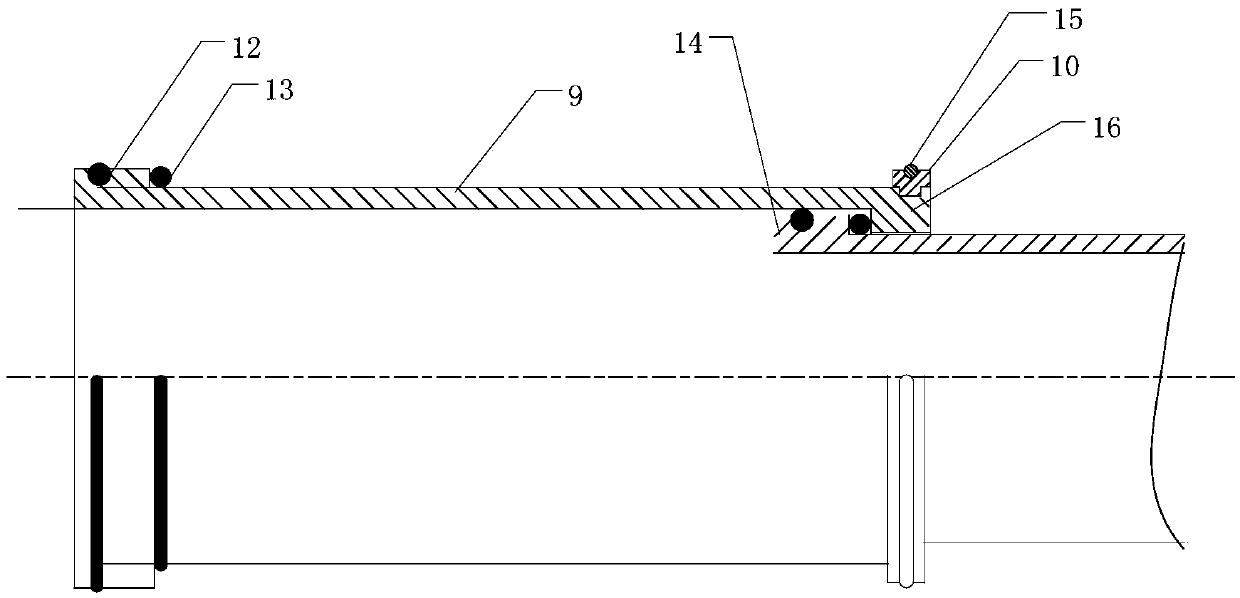

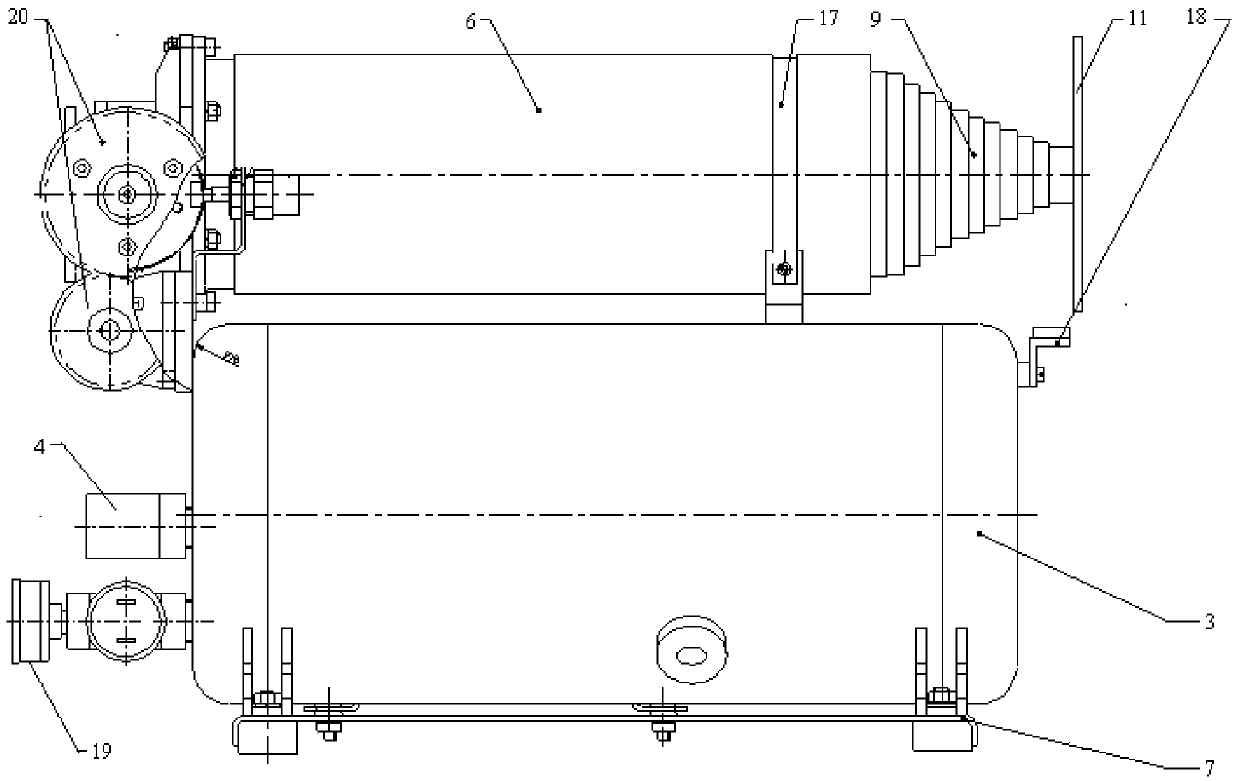

[0029] Such as figure 1 As shown, the small fully automatic multi-stage telescopic rod device of the present invention includes a telescopic rod tube. The telescopic rod tube includes a fixed tube 6 and a movable tube 9 that runs through its inner cavity and can stretch along it. The telescopic rod tube is connected with a controller 4 , the controller 4 connects the air storage tank 3 to the DC air pump 1 through the air pipeline 2; the inner cavity of the movable cylinder 9 is covered with a load platform 11 that can be stretched along it; 5. The traction roller 5 is provided with a traction wire rope 8 connected to the load platform 11 .

[0030] Under the control of the controller 4,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com