Multifunctional pressure reducing valve in front of meter

A technology of multi-function meter and pressure reducing valve, applied in the direction of functional valve type, lifting valve, valve details, etc., can solve the problems of low applicability, insufficient safety, low practical value, etc., achieve cut-off function safety, and wide application range , the effect of improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

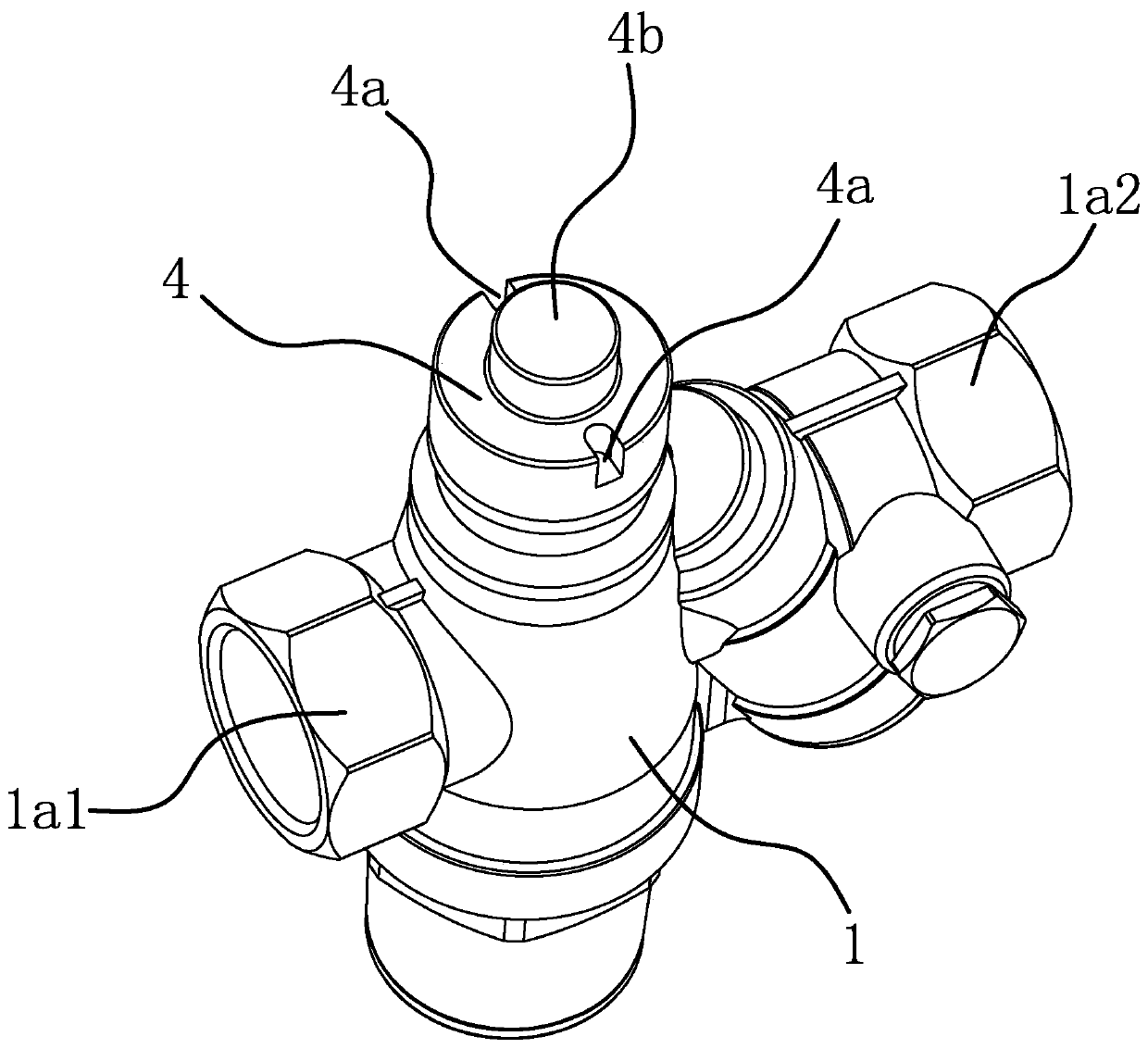

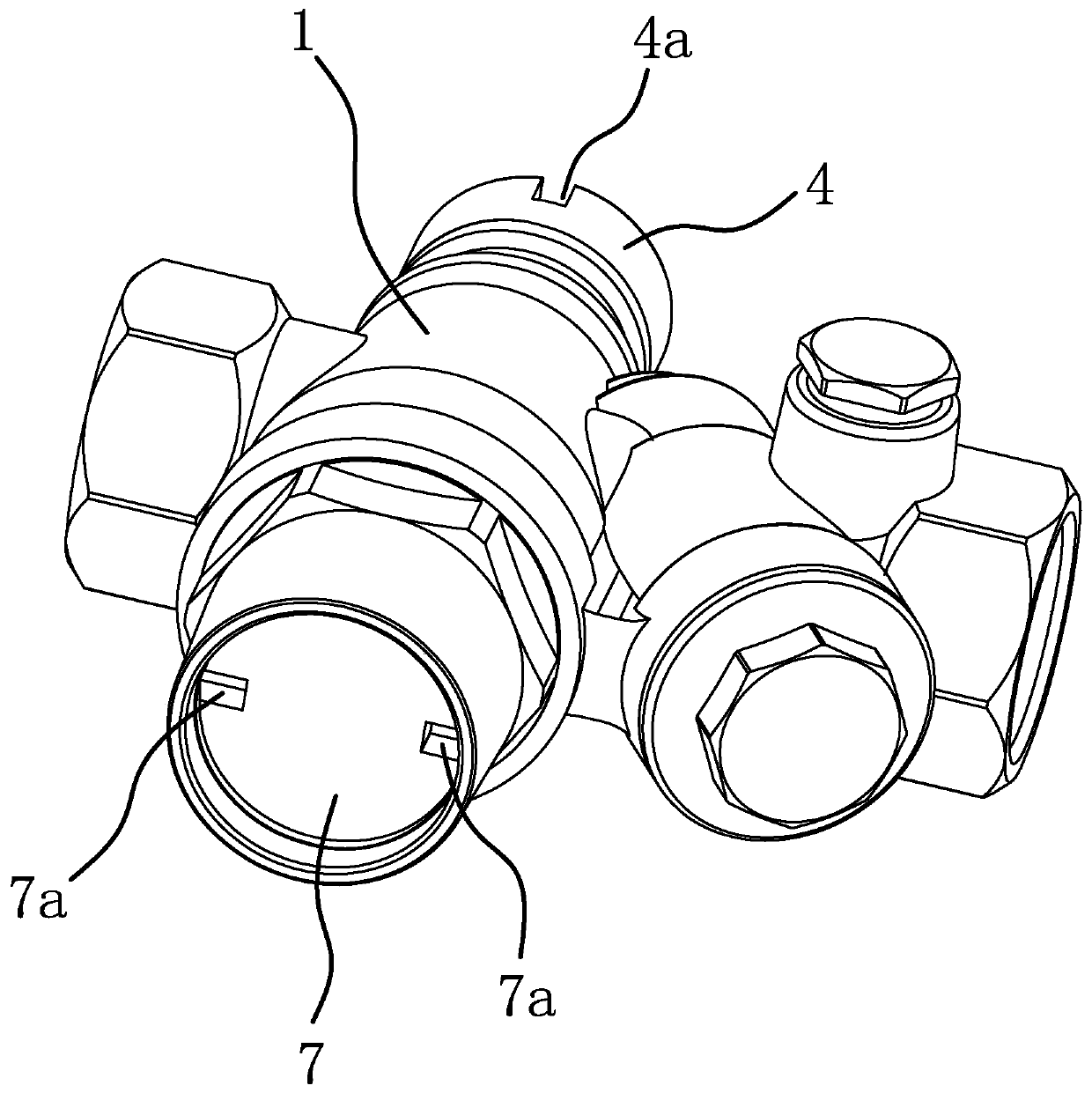

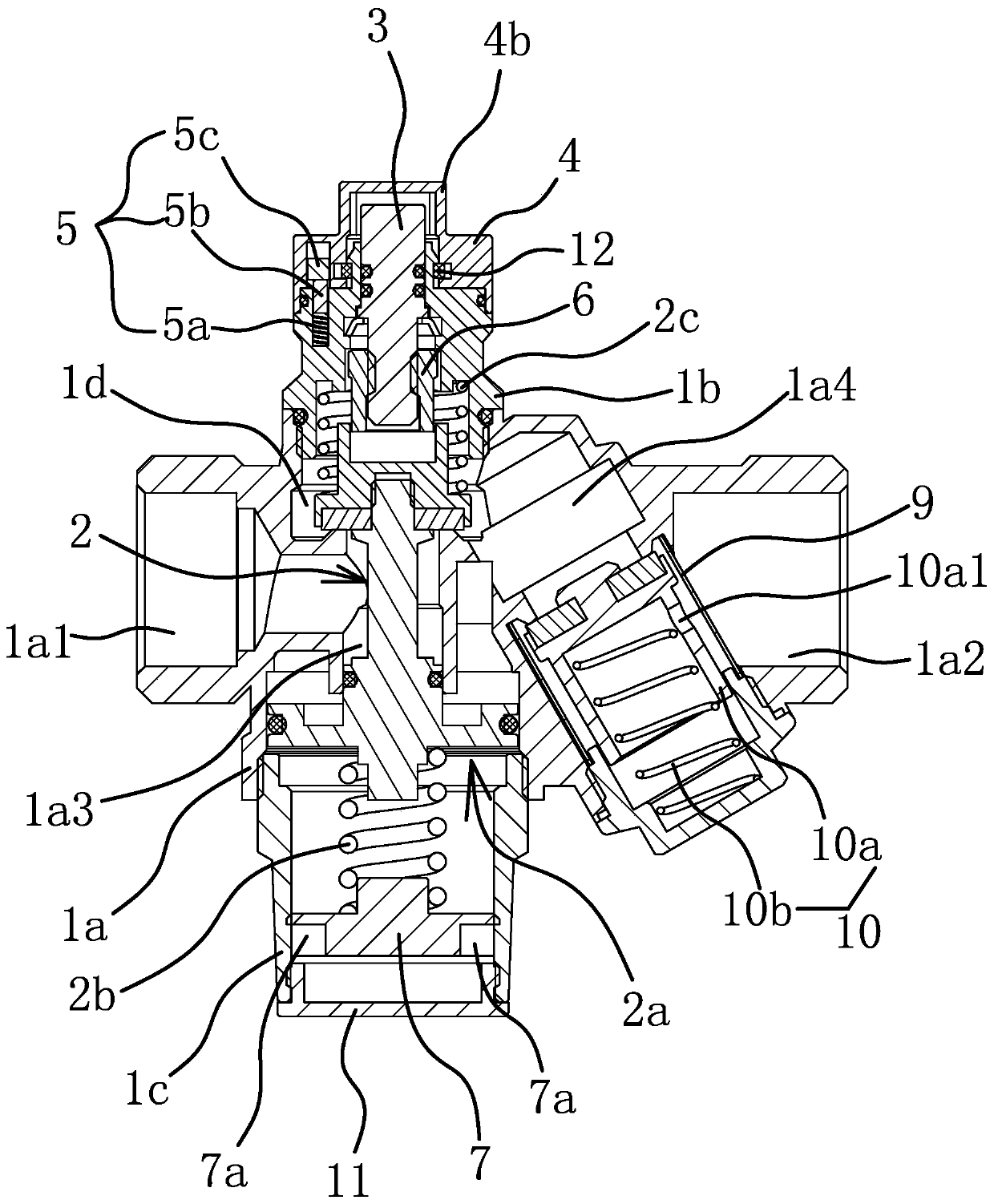

[0039] Such as Figure 1-3 As shown, the pressure reducing valve in front of the multi-function meter includes a valve body 1 whose left and right ends are the water inlet 1a1 and the water outlet 1a2 respectively. The valve body 1 is provided with a water passage 1d, and the water passage 1d is connected with the water outlet 1a2 A water inlet channel 1a3 is arranged vertically in the water passage 1d, the water inlet end 1a1 communicates with the water inlet channel 1a3, and an elastic decompression assembly 2 capable of moving up and down is arranged in the water inlet channel 1a3.

[0040] Such as image 3 and Figure 4 As shown, the elastic decompression assembly 2 includes a decompression core 2a, a decompression spring 2b and a buffer spring 2c. The decompression core 2a includes a core rod 2a1 passing through the water inlet channel 1a3, and a The baffle plate 2a2 and the water retaining head 2a3 fixed on the upper end of the core rod 2a1, the upper end of the core r...

Embodiment 2

[0051] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that: Figure 7 and Figure 8 As shown, in this embodiment, the end of the water outlet 1a2 is provided with a flaring section 1a21, and the flaring section 1a21 is provided with a control rod and a ball core 13 that can adjust the water flow of the water outlet 1a2. 13 connected, the other end of the control rod stretches out of the flaring section 1a21 and is connected with a handle 14.

[0052]The outlet of the water outlet 1a2 is set as a flaring section 1a21, and a control rod and a ball core 13 are arranged in the flaring section 1a21, so that the user can adjust the flow of the water, that is, the front pressure reducing valve of the multi-function meter is also integrated. Flow adjustment function.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com