Quick connector

A fast and fast connection technology, applied in the direction of elbows, pipes/pipe joints/fittings, branch pipelines, etc., can solve the problems of material waste, long installation time, complex structural design of elbow joints and tee joints, etc., to achieve The effect of simple structure operation and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

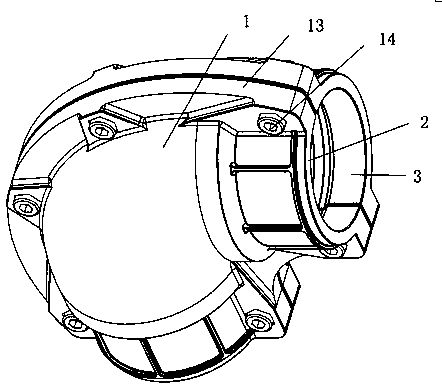

[0032] like Figure 1-4 As shown, a quick connector provided in this embodiment includes a casing 1 with an assembly channel and a sealing ring 2, the casing 1 includes more than two connection ports 3, the sealing ring 2 includes a sealing cylinder 4 and There are 3 sealed outlets 5 with the same number as the connection ports, and each sealed outlet 5 is located in the connection port 3. The shell 1 also includes an upper half shell 6 and a lower half shell 7 that can be assembled and disassembled. Half shell 6 and lower half shell 7 are all provided with a semicircular groove 8, and the breach on the semicircular groove 8 on the upper half shell 6 and the lower half shell 7 is combined mutually and constitutes for Install the position-limiting pipeline 9 of the sealing cylinder 4, be provided with the first semicircular notch 10 that is identical with the number of connection ports 3 and the distribution position of the connection port 3 tops on the upper half housing 6, an...

Embodiment 2

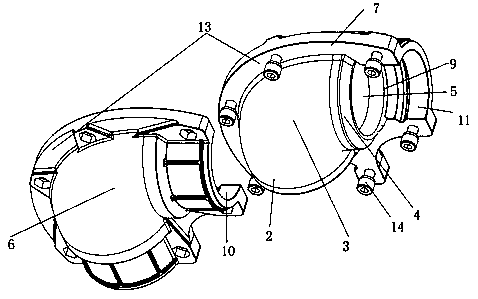

[0035] like Figure 5As shown, the general structure of a quick connector provided in this embodiment is the same as that of Embodiment 1, the difference is that, as a preference, in order to facilitate the three-channel connection, the outer shell 1 and the sealing cylinder 4 are in the form of a three-way pipe , that is, the outer shell and the inner sealing cylinder 4 are set in the form of a tee. When installing, first use a special convex tube machine to protrude a ring of flanges on both sides of the upper half of the shell 6 and the lower half of the shell 7 at the corresponding positions. Extend the convex edge 13, and then insert the connecting pipe body part that needs to be installed on the three sides into the sealing ring 2, and then place the semicircular grooves 8 on both sides of the upper half shell 6 and the lower half shell 7 in the sealing ring 2 The two sides are spliced together to form the limit pipe 9 of the seal ring 2. At the same time, the two side...

Embodiment 3

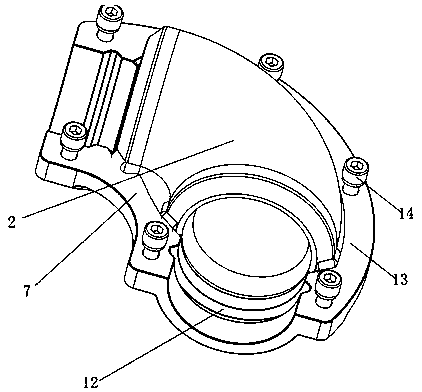

[0037] like Figure 6-8 As shown, the general structure of a quick connector provided in this embodiment is the same as that in Embodiment 1, the difference is that, as a preference, in order to improve the position-limiting effect, a position-limiting protruding ring 15 is provided on the outer wall of the sealing outlet 5, and the The sealing outlet 5 cooperates with the position-limiting convex ring 15 to form a hook structure 21, and the structural structures 21 on both sides cooperate with the half-side inclined steps 22 provided on the corresponding side of the semicircular groove 8, and the upper half of the housing 6 and the lower half After the two sides of the housing 7 are aligned, the two half-side inclined steps 22 on the same side cooperate with each other to form a limiting step surface 23 for clamping the hook structure 21 .

[0038] By setting the limit protruding ring 15 and the setting of the hook structure 21, and using the limit step surface 23, after the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com