Vacuum drying oven and working method thereof

A technology of vacuum oven and working method, which is applied in the direction of drying, drying machine, local stirring dryer, etc., which can solve the problems affecting product quality and vacuum degree drop, and achieve the effect of reliability and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

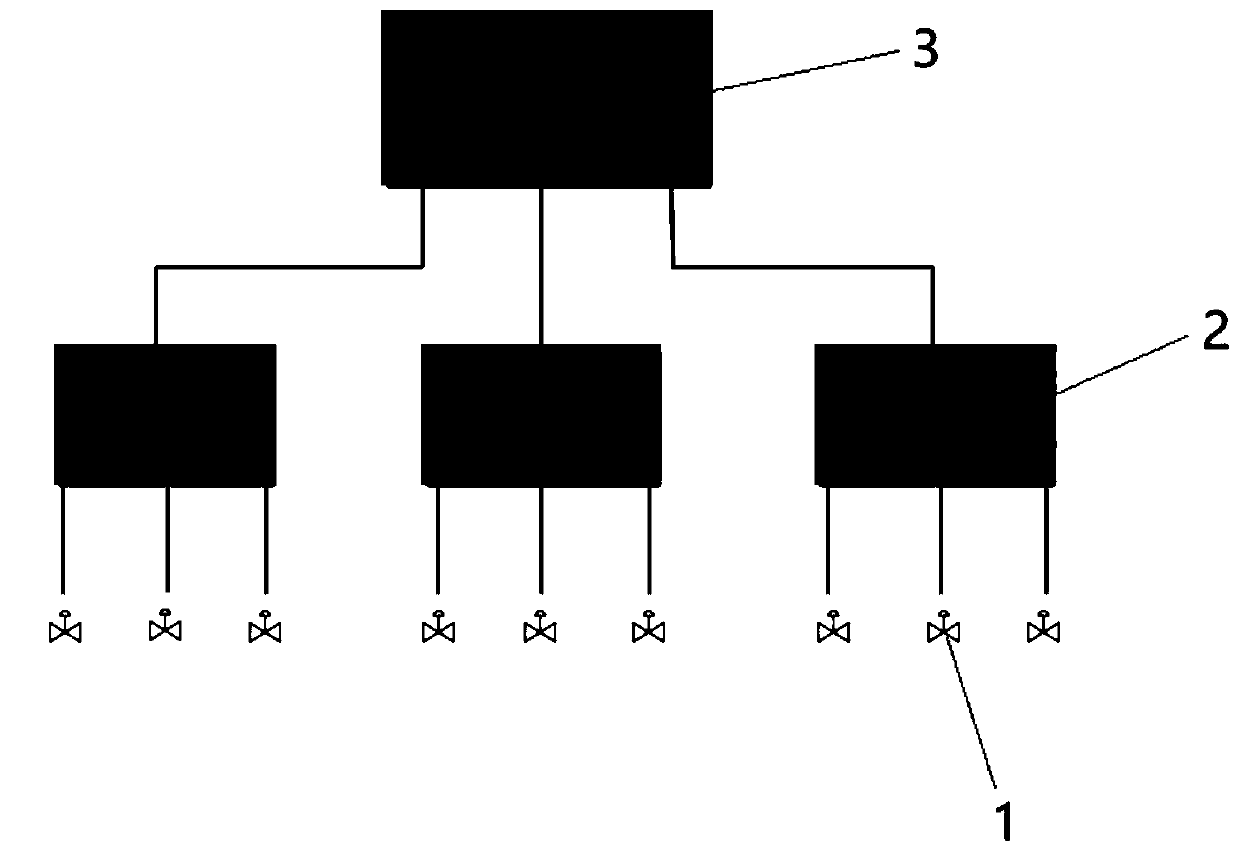

[0017] see figure 1 , one dry vacuum pump 3 connected to three ovens, one oven has three layers, W1, W2, W3, W4, W5, W6, W7, W8, W9 represent each layer of ovens, each of W1-W9 ovens Vacuum valve 1 is controlled by a PLC control system 2. When any vacuum valve 1 in W1-W9 is opened to work, other operations need to be performed after the vacuuming of the oven on this layer is completed;

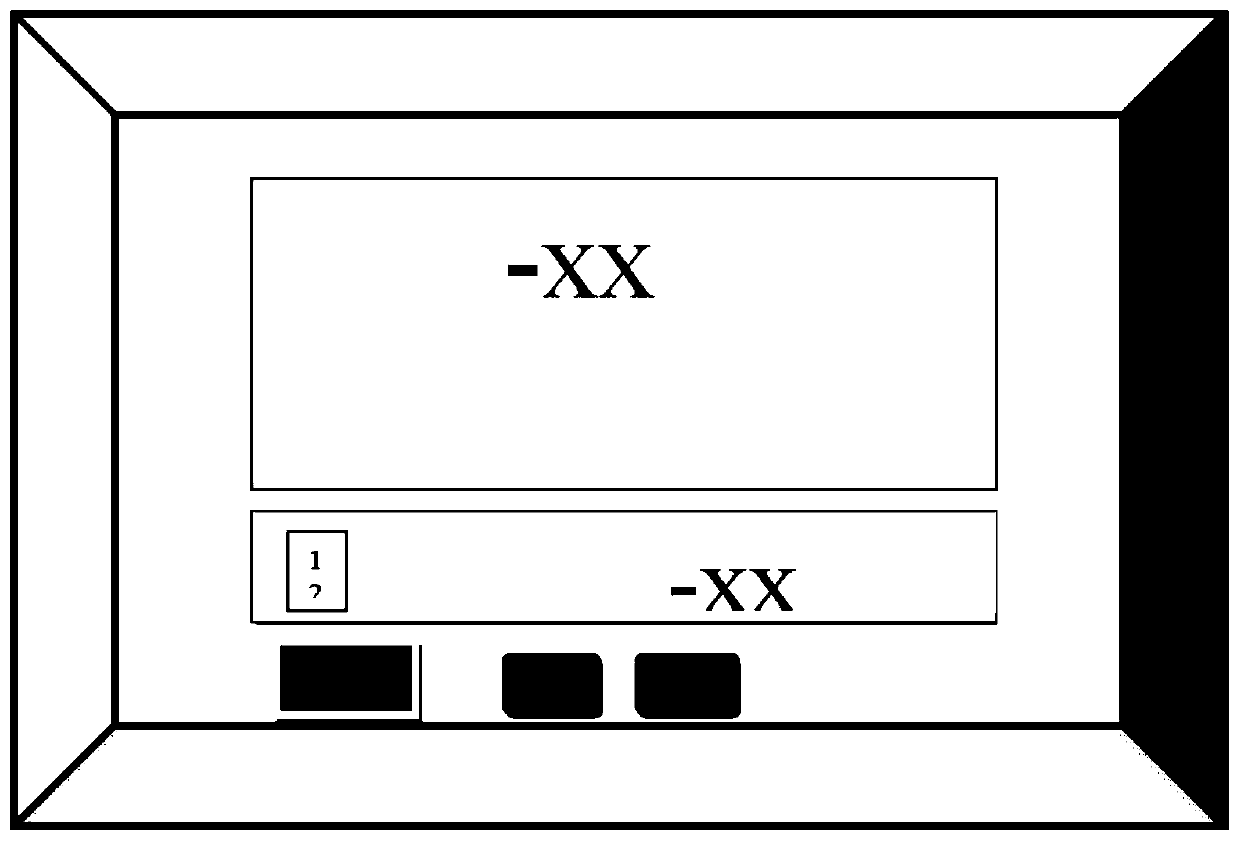

[0018] see figure 2 , to set the vacuum instrument, press the MODE key to display lo-1, press the ↑, ↓ key to set the required vacuum degree, press the MODE key again to display hi-1, press the ↑, ↓ key to set the required minimum vacuum degree , when the value is lower than this value, the valve will be automatically opened and vacuumed to the vacuum value set by lo-1; press the MODE key once again, and lo-2 will be displayed, press the ↑ and ↓ keys to set the vacuum degree that needs to be maintained after the project is completed, and then press the MODE key Once, hi-2 is displayed, pres...

Embodiment 2

[0021] The vacuum gauge L0-1 of each layer of oven W1-W9 is set to -98kPa, Hi-1 is set to -95kPa, L0-2 is set to -96kPa, and Hi-2 is set to -92kPa. Assuming that W1 is pressed to run automatically at this time, W1 will start heating and vacuuming at the same time, and the vacuuming will not stop until -98kPa. If W2 is already running at this time, and the vacuum degree of W2 drops below -95kPa, it needs to be vacuumed. At this time, the PLC sends a command to wait for W2 to vacuumize. If W3-W9 is also in the same situation as W2, then wait for vacuuming according to the order in which the ovens on each layer drop below -95kPa.

Embodiment 3

[0023] The vacuum gauge L0-1 of each layer of oven W1-W9 is set to -98kPa, Hi-1 is set to -95kPa, L0-2 is set to -96kPa, and Hi-2 is set to -92kPa. Assuming that W2 is already running, the vacuum degree has dropped below -95kPa, and it is being vacuumed to make the vacuum degree reach above -95kPa. At this time, press W1 to automatically run, and the PLC will issue a command to W1 to vacuumize and wait until the vacuum degree of W2 reaches above -95kPa. Execute the W1 vacuum command after the display shows that the pumping has stopped.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com