Testing and calculation method for determining material scale distance effect curve

A technology of effect curve and calculation method, which is applied in the direction of calculation, analysis of materials, and testing of material strength by applying stable tension/pressure to achieve high precision and improve efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

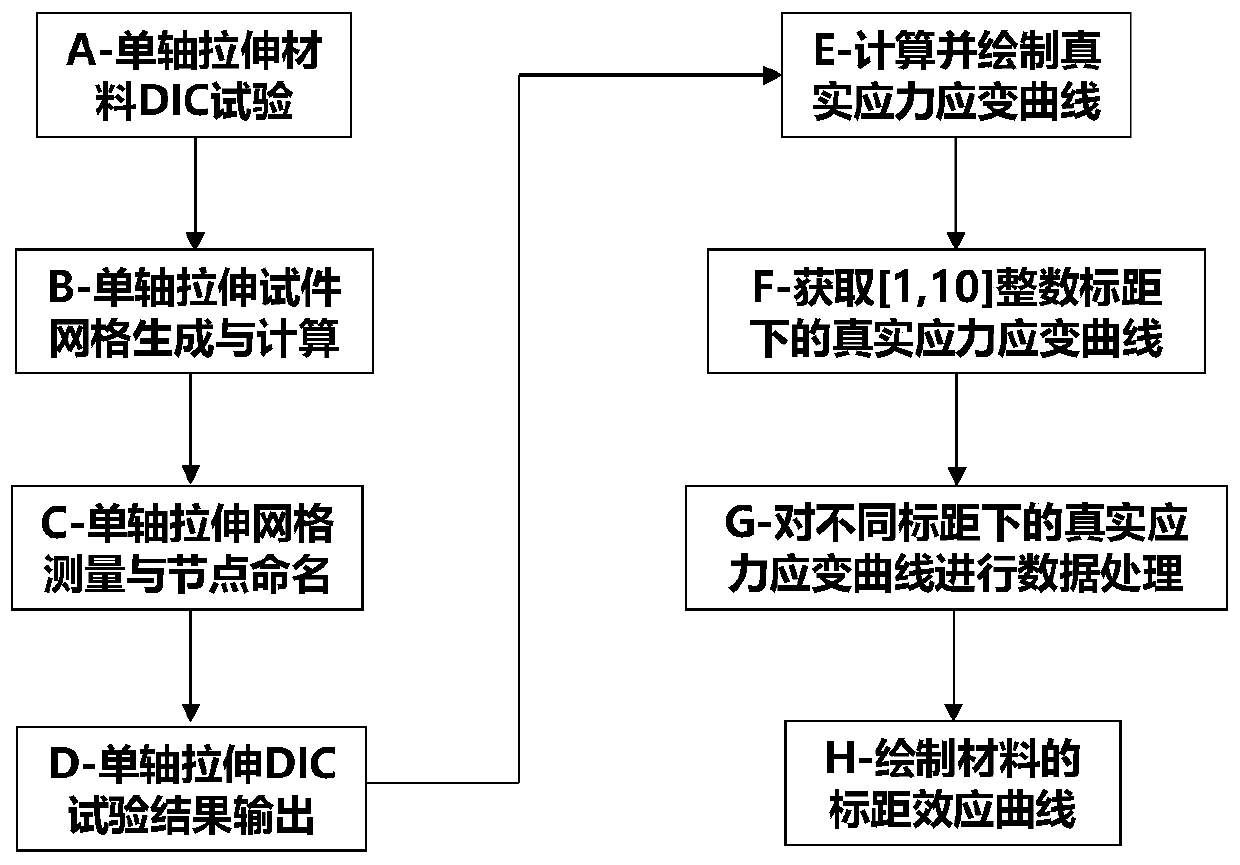

[0090] In this embodiment, the material DP780 is used as an example to output the results under the integer gauge length from 1.0mm to 10mm. The model of the tensile testing machine used is Zwick / Roell Z050, the DIC test system is the ARAMIS system of GOM Company in Germany, and the data processing software For EXCEL, specify the test and calculation method of measuring material gauge length effect curve of the present invention, as figure 1 As shown, it includes the following steps:

[0091] Step 1, uniaxial tensile material DIC test, including the following steps:

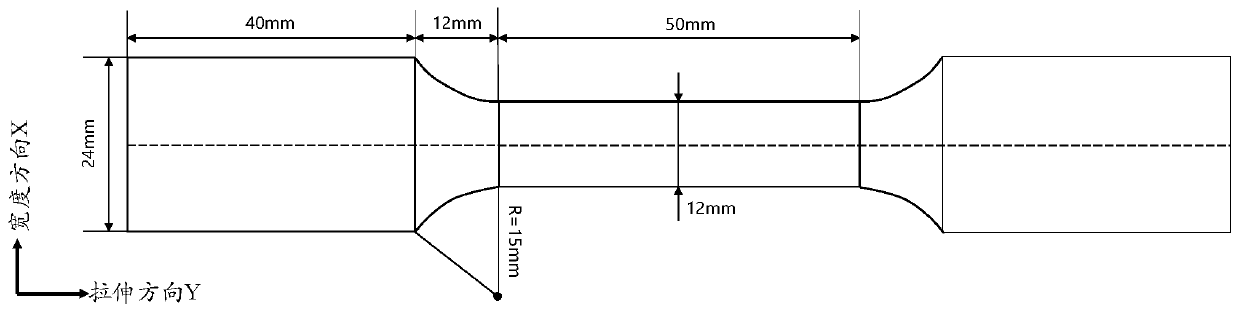

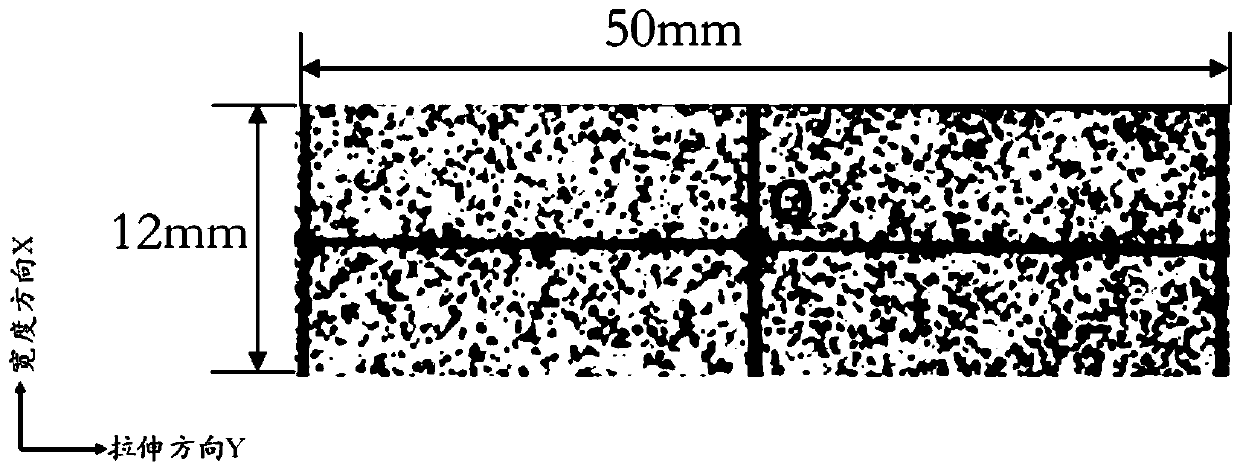

[0092] The first step is to make the size of the tensile specimen for the uniaxial tensile DIC test of the material DP780, such as figure 2 As shown, the gauge length is 50mm, the width is 12mm, the thickness is 1.4mm, and the initial cross-sectional area is 16.8mm 2 , spray matte paint on the surface of one side of the tensile test piece, and the 50mm gauge length section of the tensile test piece after spray...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com