Structural error determination method and device

A determination method and error technology, applied in the field of structural error determination method and device, can solve the problems of difficult structural error, difficult structural error detection of internal parts, affecting the heat dissipation performance of equipment, etc., so as to improve efficiency and quality control, and determine high efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

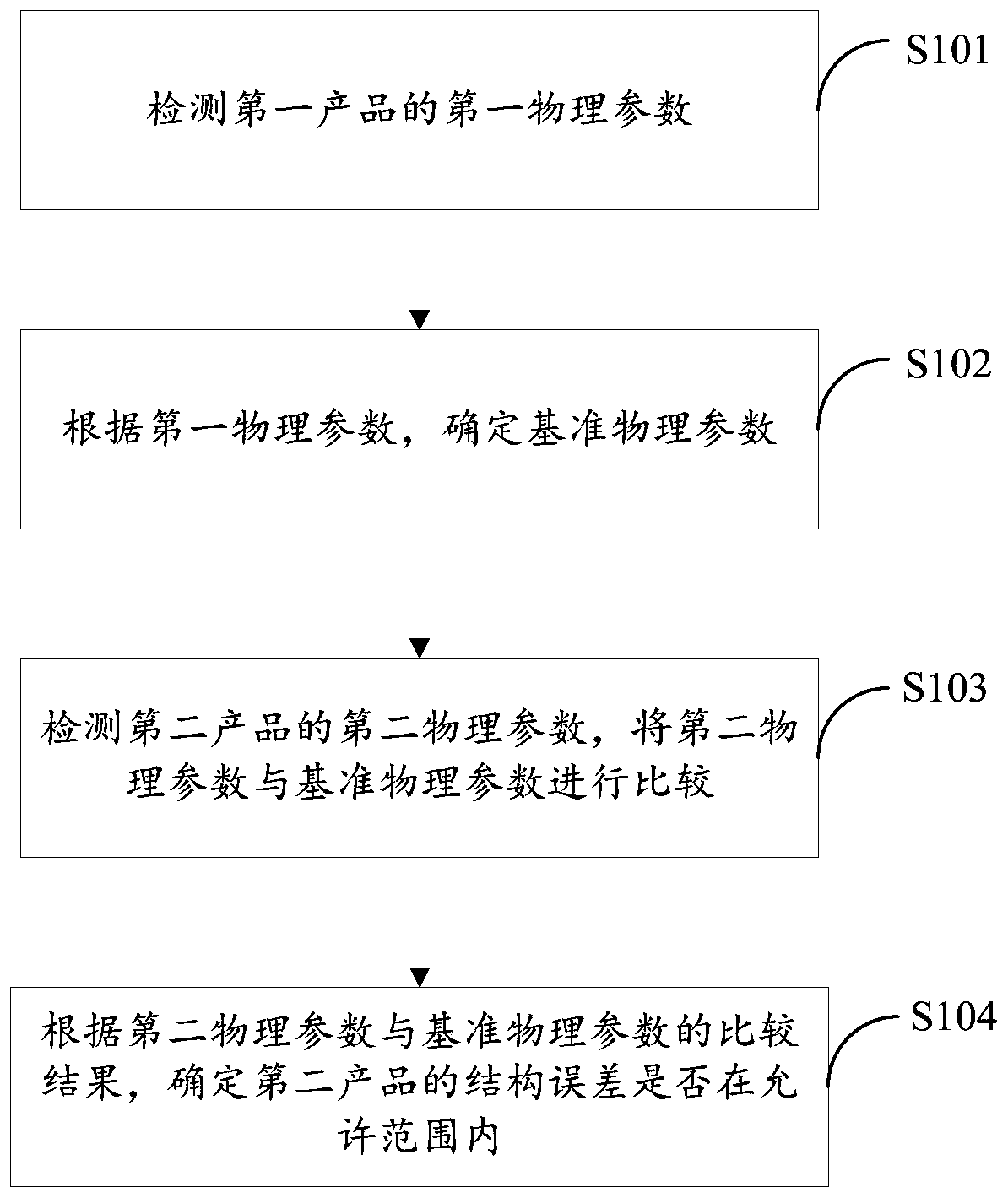

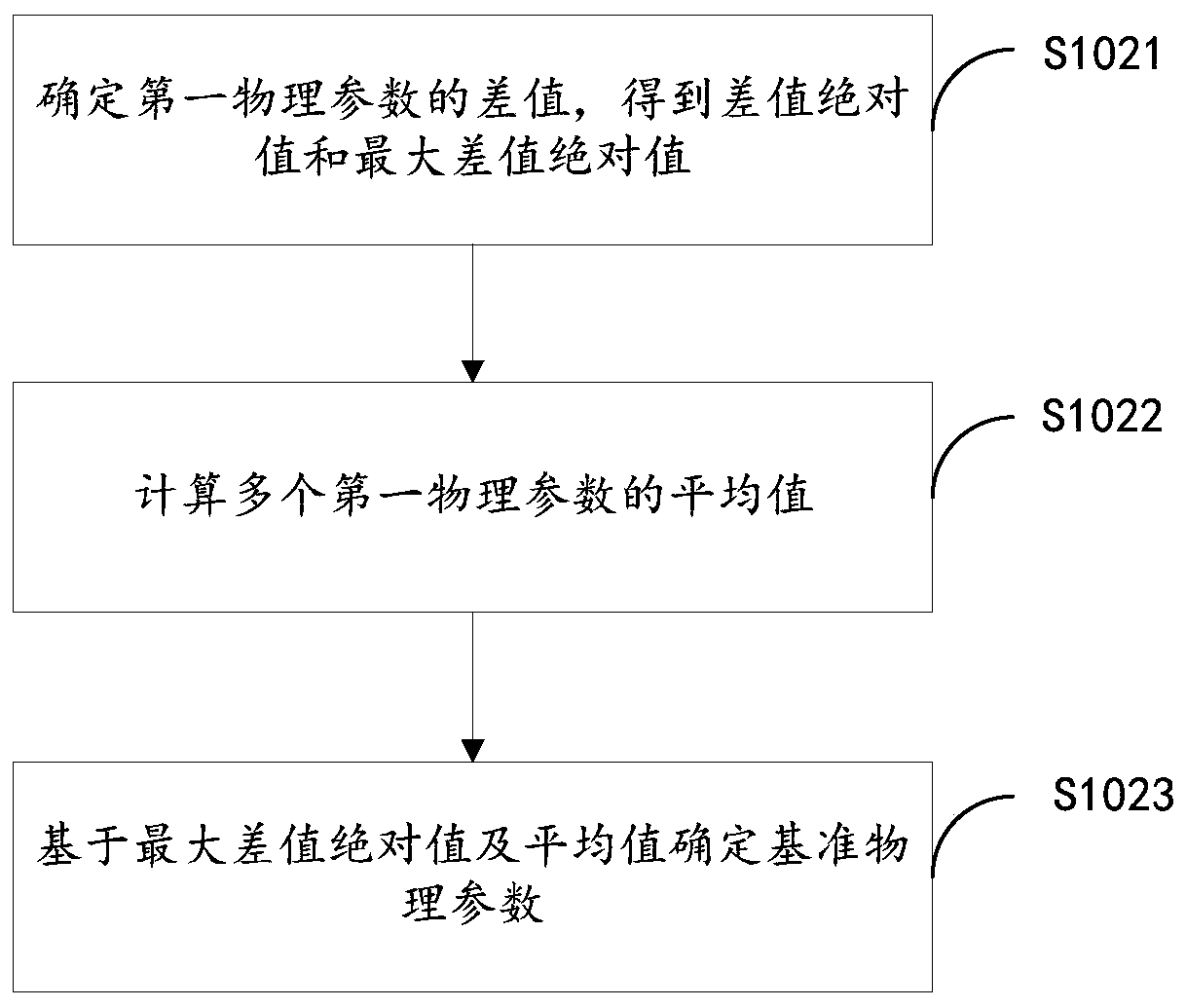

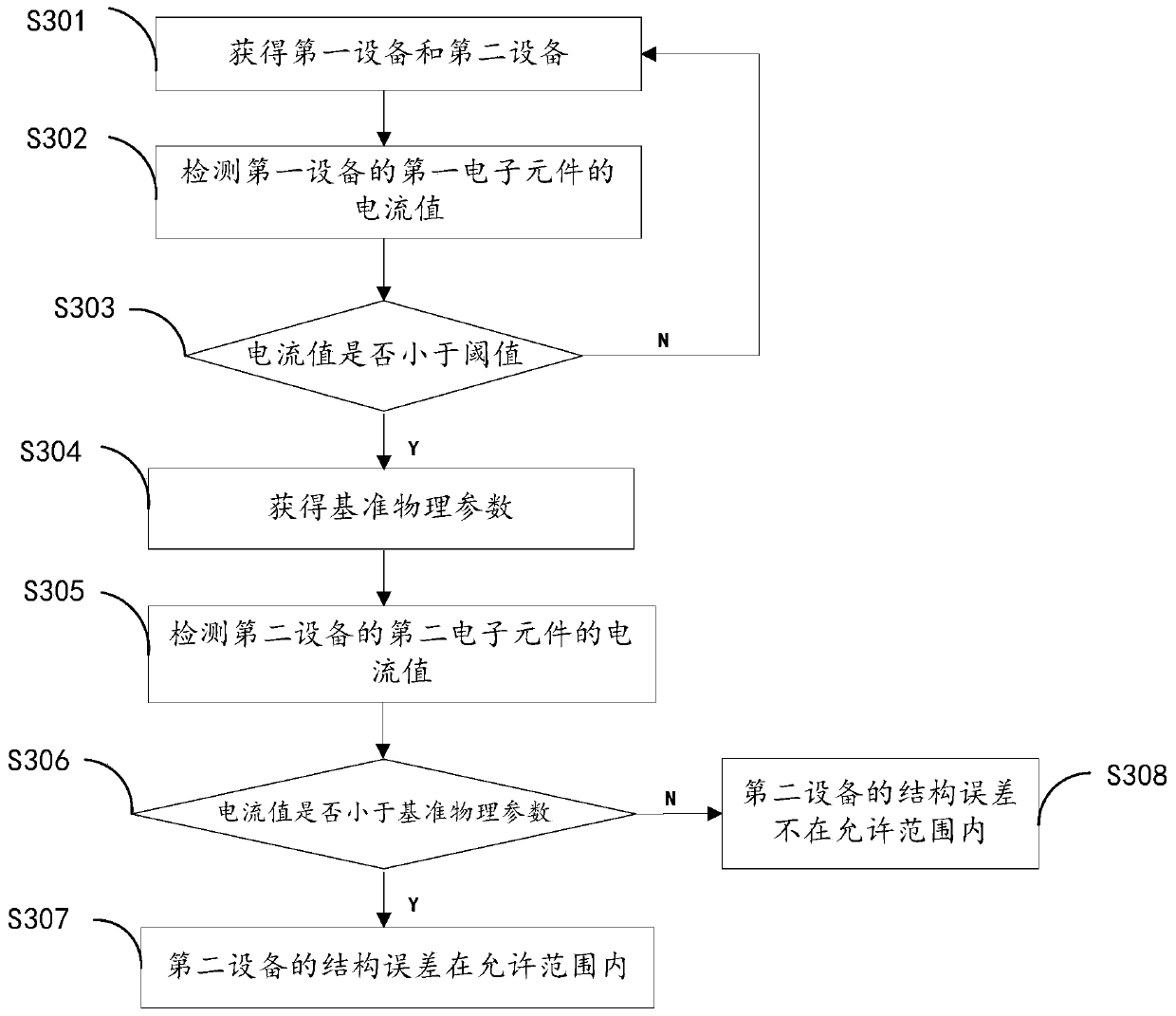

[0012] Hereinafter, exemplary embodiments according to the present application will be described in detail with reference to the accompanying drawings. Apparently, the described embodiments are only some of the embodiments of the present application, rather than all the embodiments of the present application. It should be understood that the present application is not limited by the exemplary embodiments described here.

[0013] Application overview

[0014] At present, the control of equipment error in machining and assembly mainly lies in setting the tolerance of each part and assembly tolerance first during design. For the detection and determination of errors, direct measurement methods are generally used, such as measuring the diameter of the shaft. Some dimensions cannot be measured directly, so indirect measurement methods are required, such as measuring angle, taper, hole center distance, etc., and then other errors can be obtained through calculation. When the shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com