Multi-objective optimization method for design and development of diesel vehicle postprocessor

A multi-objective optimization, post-processor technology, applied in electrical digital data processing, special data processing applications, chemical process analysis/design, etc., can solve problems such as performance degradation, avoid repetitive experiments, save experimental resources and manpower The cost of material and financial resources and the effect of improving the reliability of development and design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

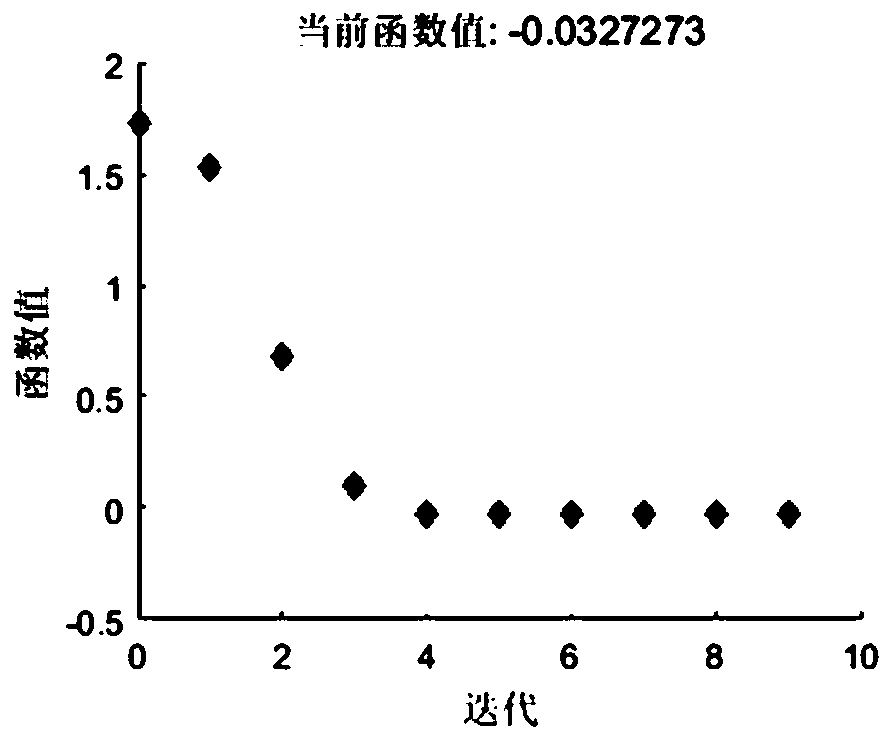

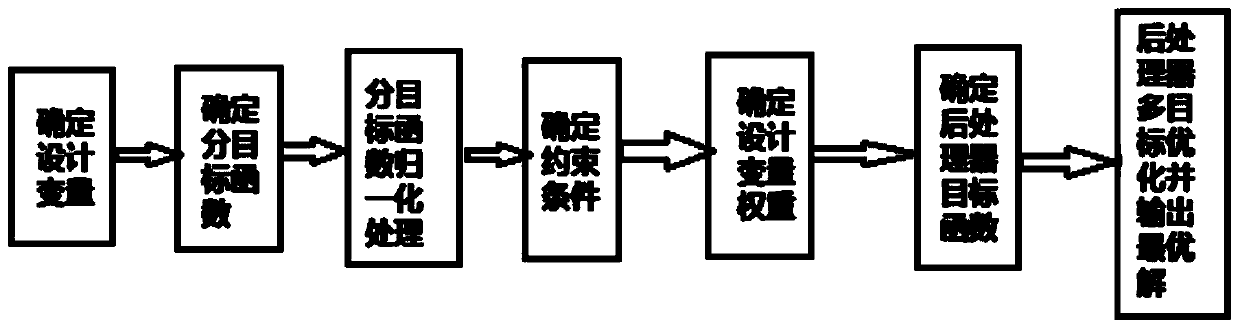

[0047] The basic idea of the multi-objective optimization method for the design and development of the diesel vehicle post-processor of the present invention is to decompose the post-processor design and development multi-objective optimization problem into various sub-objective functions according to the design sub-objectives.

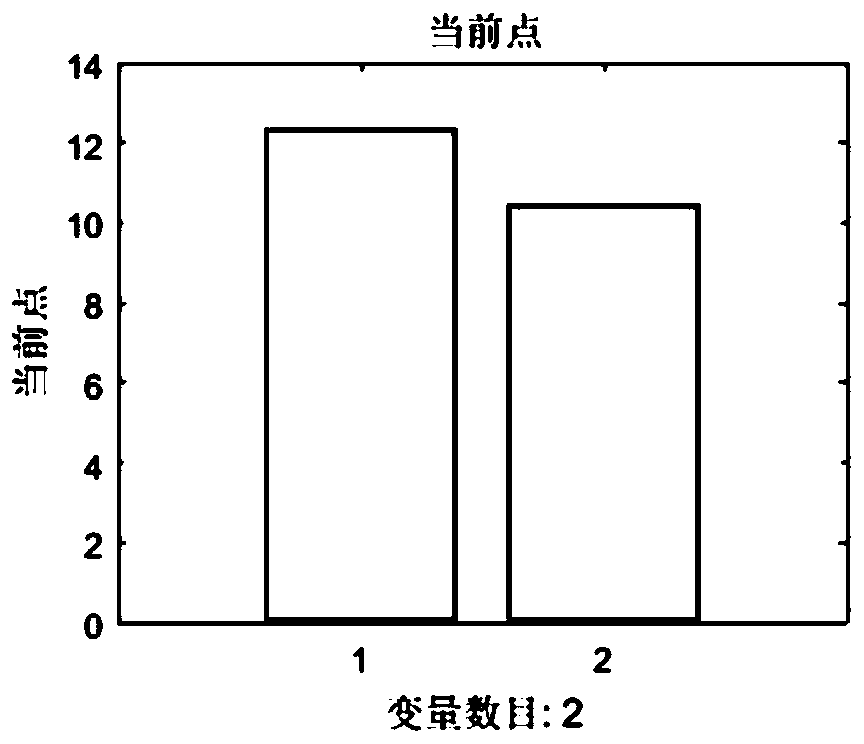

[0048] The main key factors affecting the design of after-processor for diesel vehicles are: NOx (nitrogen oxide) conversion efficiency of after-processor, PM (particulate matter) filtration efficiency, pressure loss of after-processor, initial installation cost and operating cost of after-processor, post-installation The fuel consumption of the engine after the processor is increased, the original emission level of the engine, the average exhaust temperature of the engine WHTC (World Harmonized Transient Cycle) cycle, etc. These influencing factors are the design variables of the sub-objective function. The design variables can be added or deleted a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com