Particle traps and parameter optimization methods for DC gas-insulated transmission lines

A transmission line and gas insulation technology, applied in the field of particle traps and parameter optimization of DC gas insulated transmission lines, can solve problems such as reducing the insulation performance of equipment, and achieve the effects of inhibiting activity, avoiding a large number of repetitive experiments, and inhibiting particle charging.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be further described below in conjunction with the accompanying drawings.

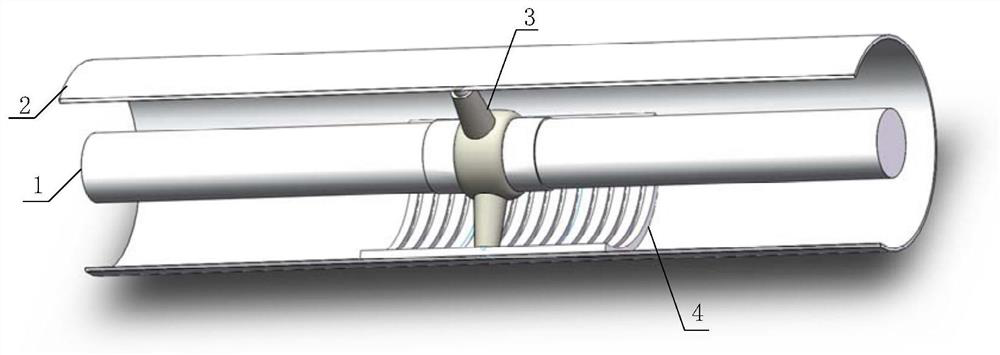

[0035] Such as figure 1 As shown, it is a schematic diagram of the pipeline structure installed with a metal particle trap for DC GIL of the present invention. The particle trap 4 is arranged near the insulator 3 of the DC GIL cavity. The cavity includes an aluminum alloy conductor 1 with a radius of 60 mm, an aluminum alloy shell 2 with an inner diameter of 180 mm, and a post insulator 3. The overall structure can withstand up to 0.7MPa air pressure.

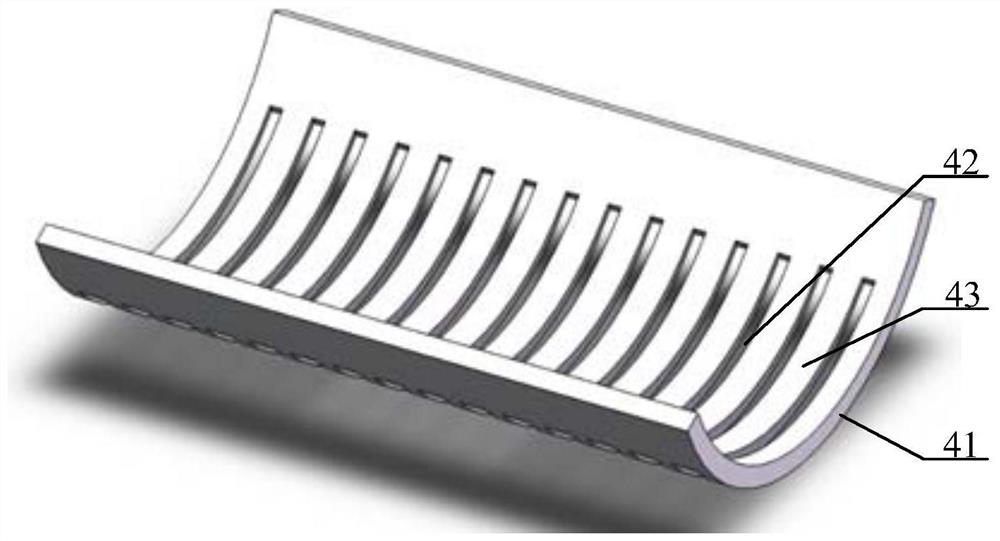

[0036] Particle trap 4 specific structure such as figure 2 , 3 shown.

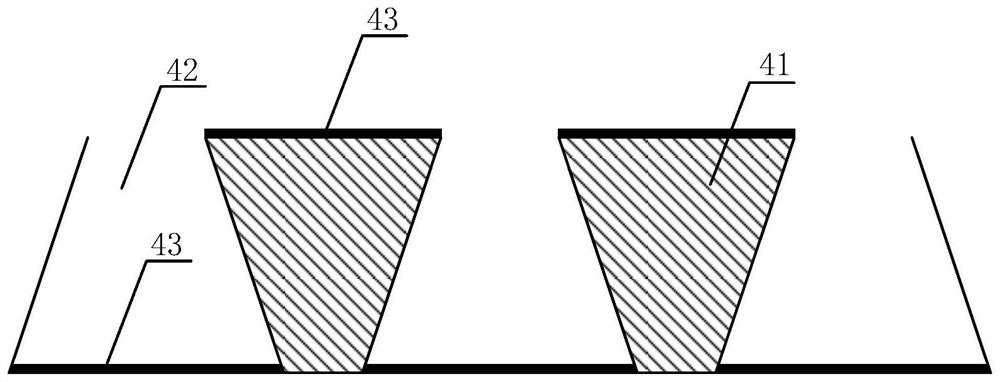

[0037] The present invention provides an embodiment of a DC gas insulated transmission line (GIL) particle trap 4, which includes a trap base 41, a particle capture groove 42, and an insulating dielectric film 43, wherein the trap base 41 is arranged on the inner wall of the DC GIL shell and is connected to the inner wall Tight fit, the partic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com