Forging ex-situ identification and positioning method in robotized die forging process

A positioning method and robot technology, applied in the direction of instruments, image data processing, calculation, etc., to improve positioning accuracy and solve the problem of high-temperature forging out-of-position identification and positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

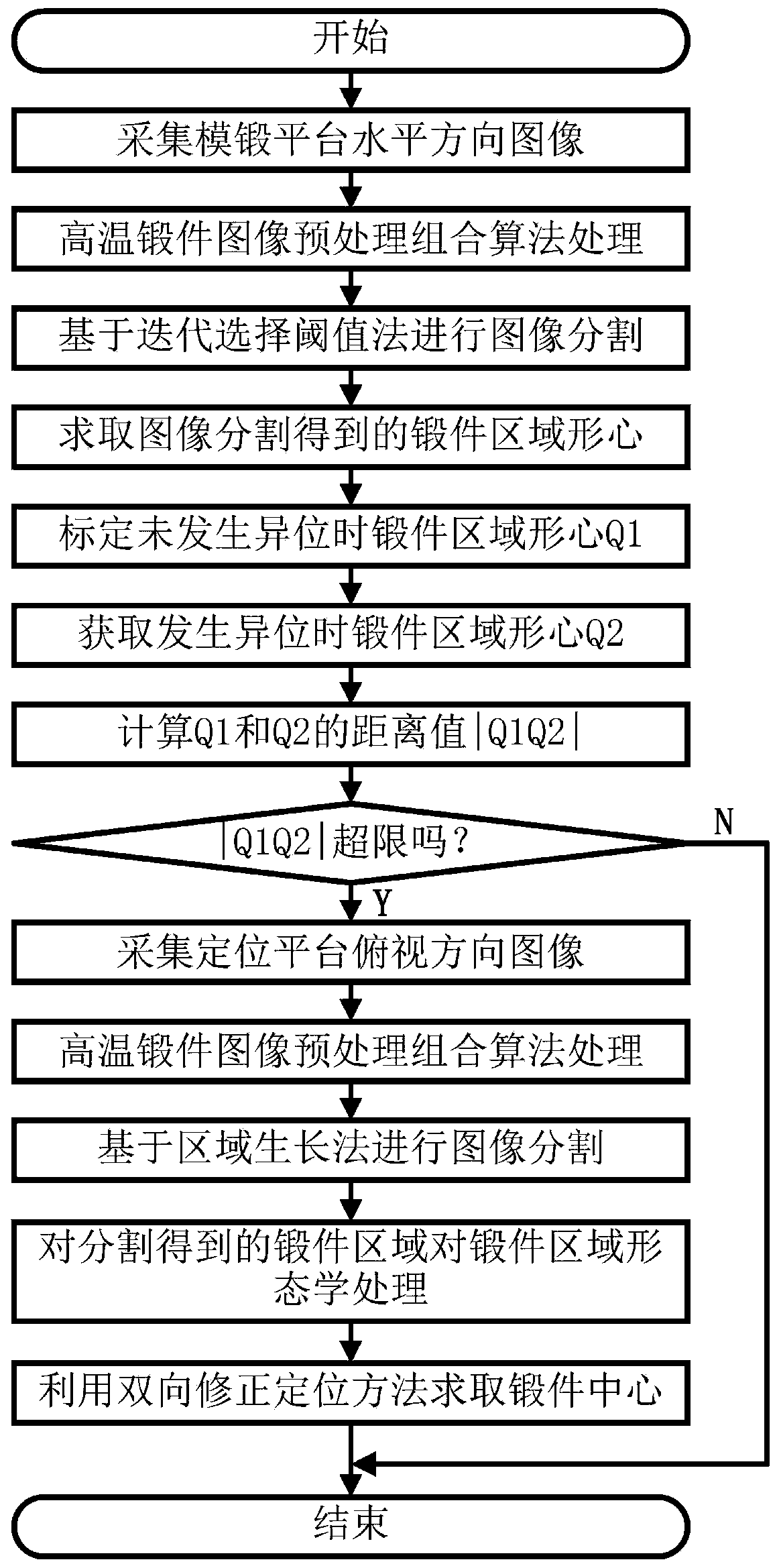

[0042] Depend on figure 1 It can be seen that the method for identifying the out-of-position forgings in the robotized die forging process includes the following steps:

[0043] (1) Using the high temperature forging image preprocessing combination algorithm to process the image of the die forging platform taken in the horizontal direction;

[0044] (2) Using iterative selection threshold method for image segmentation to obtain forging area;

[0045] (3) Find the centroid coordinates of the forging area after the division;

[0046] (4) According to steps (1) to (3), calibrate the centroid coordinate Q1 of the forging area when no misalignment occurs;

[0047] (5) According to steps (1) to (3), obtain the centroid coordinate Q2 of the forging area when the misalignment occurs;

[0048] (6) Calculate the distance value between Q1 and Q2. If the value exceeds the set threshold, it is considered that the forging is out of position, otherwise it is considered that the forging is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com