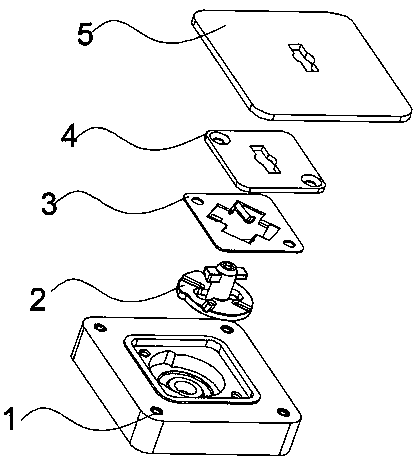

LED display screen module maintenance mechanism

A technology of LED display and display module, applied in the direction of instruments, identification devices, etc., can solve the problems of unable to lock, lack of versatility of box material thickness, prone to misoperation, etc. Risk, good market application value, the effect of reducing the difficulty of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

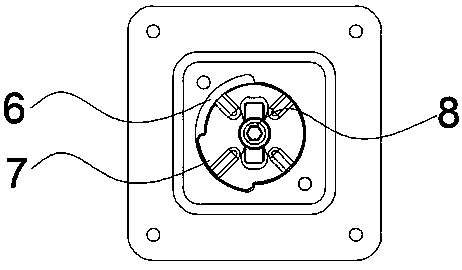

[0024] The difference between the second embodiment and the above is that at least two of the plurality of concave slots and the plurality of convex elastic pieces are provided.

Embodiment 3

[0025] The difference between the third embodiment and the above is that the clamping post 8 is made of precision casting of stainless steel.

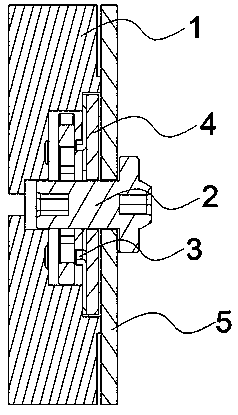

[0026] The working principle of the present invention: the LED display module maintenance mechanism is realized by the structure of the lock column 2 installed in the display module 1, the lock column 2 is made of stainless steel material, and the front and rear ends of the lock column 2 are set There is a maintenance hole corresponding to the hexagonal wrench. For front and rear maintenance, use the corresponding hexagonal wrench to insert into the hexagonal hole in the lock cylinder 2 for maintenance; the maintenance mechanism of the LED display module 1 can adapt to existing different materials The LED display module 5 with different material thickness exerts an elastic force on the lock cylinder 2 through the lock cylinder shrapnel 3 with elastic deformation ability, and when the corresponding lock cylinder 2 is fixed on the LED dis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com