Single-winding forward and reverse excitation auxiliary power supply circuit

An auxiliary power supply, forward and flyback technology, applied in the direction of electrical components, electric variable adjustment, instruments, etc., can solve the problems of insufficient power supply of products, large transient energy consumption, and reduced product reliability, so as not to affect product reliability, The effect of simple circuit structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

[0028] A single-winding forward and flyback auxiliary power supply circuit includes a forward energy storage module, a forward voltage stabilizing module, a flyback energy storage module, and a flyback voltage stabilizing module. The forward energy storage module and the flyback energy storage module share a secondary auxiliary winding. When the winding is forward, the energy storage element inside the module is charged through the forward energy storage module; when the winding is flyback, the energy storage element inside the module is charged through the flyback energy storage module. The forward energy storage module outputs a forward voltage, and the flyback energy storage module outputs a flyback voltage.

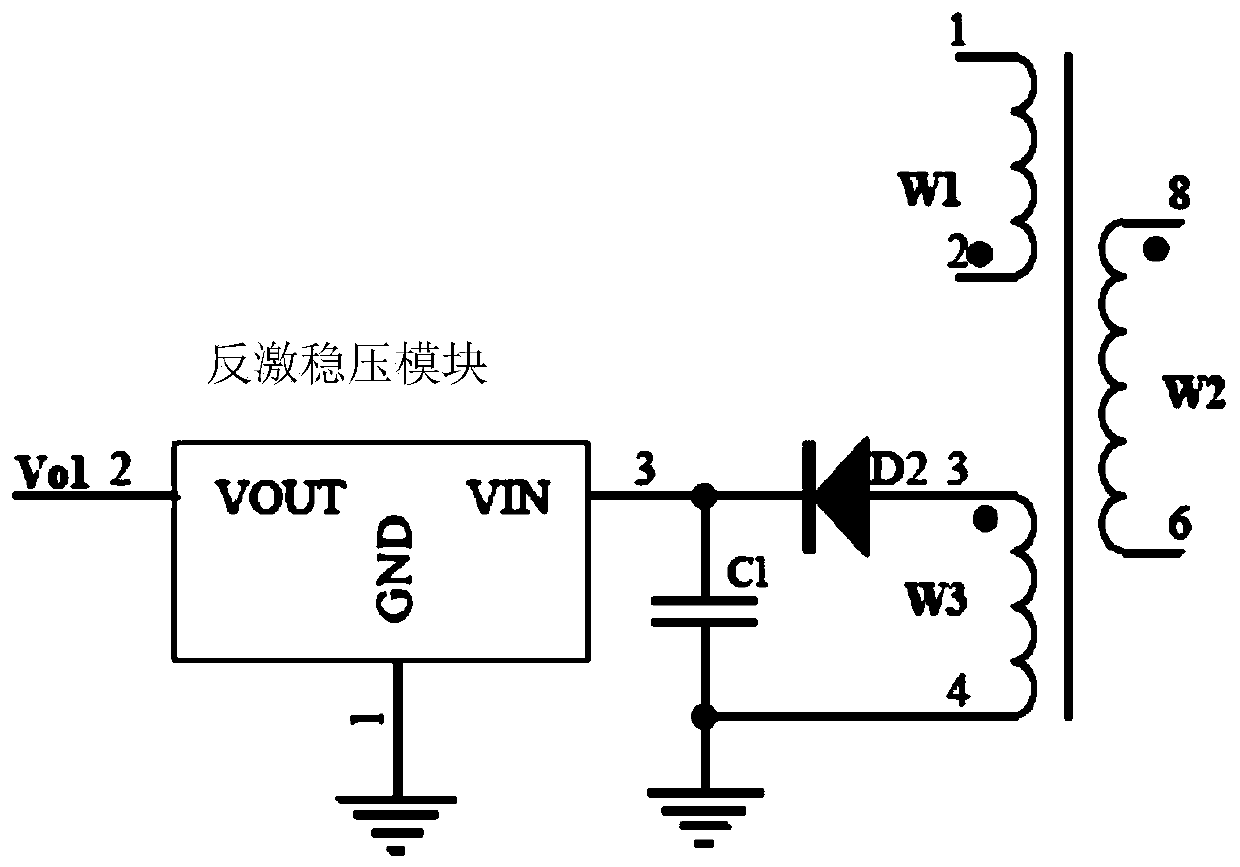

[0029] Such as image 3 It is the schematic circuit diagram of the first embodiment of the present invention, and the circuit structure of each module is as follows:

[0030] The flyback energy storage module includes a first energy storage capacitor C1, a third aux...

no. 2 example

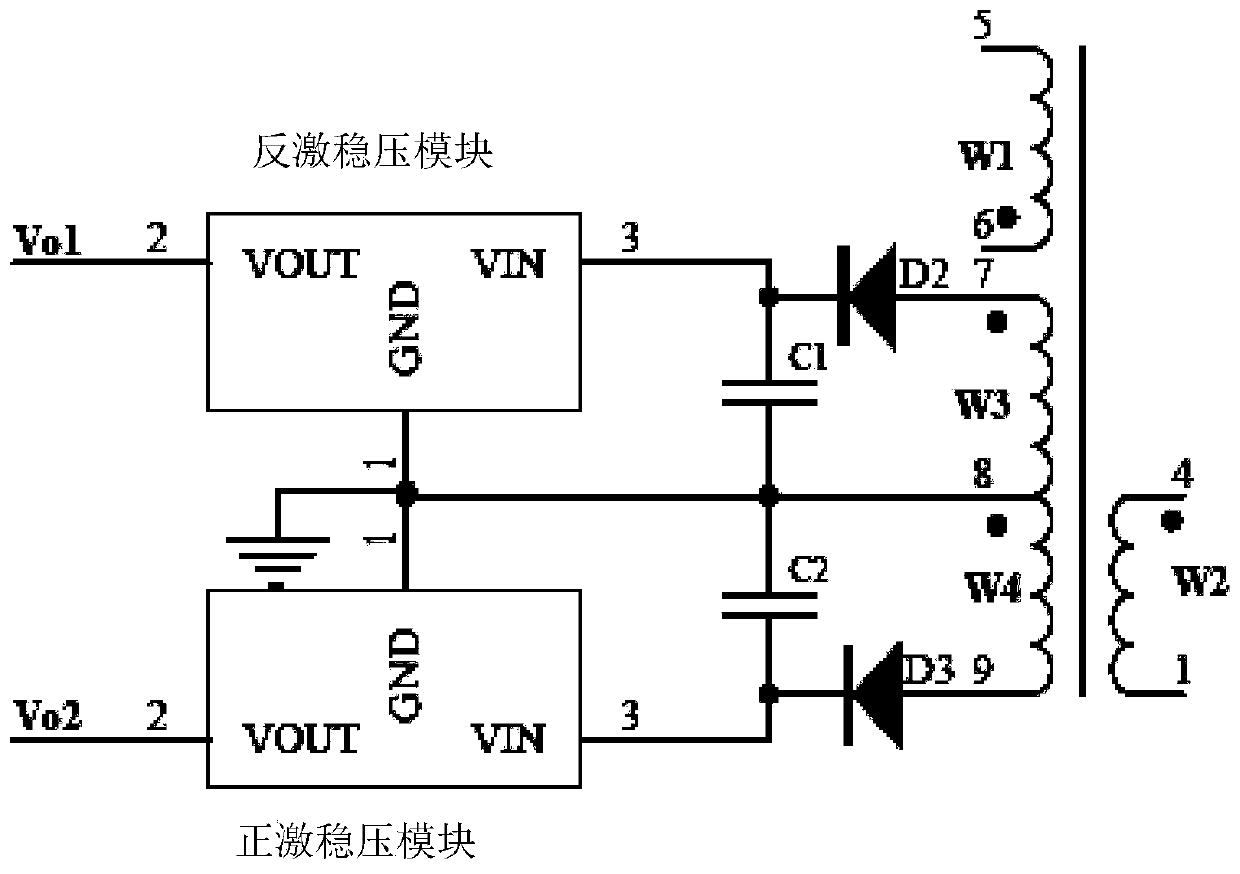

[0035] Such as Figure 4 As shown, it is the working principle diagram of the second embodiment. Compared with the first embodiment, the difference is that in this embodiment, the output terminal of the forward energy storage module is connected to the forward voltage regulator module to output a stable voltage, and the flyback The output end of the energy storage module is connected to the flyback regulator module to output a stable voltage. In the first embodiment, a straight-through wire is used for direct output.

[0036] Both the forward voltage stabilizing module and the flyback stabilizing module can use a linear voltage stabilizing circuit. Such as Figure 8 , the linear regulator module includes a first switch tube Q1 of an N-channel MOS transistor, a first resistor R1, a first voltage regulator tube Z1, a first input voltage Vin, and a first output voltage Vo. The first input voltage Vin is connected to the drain of the first switch tube, one end of the first resi...

no. 3 example

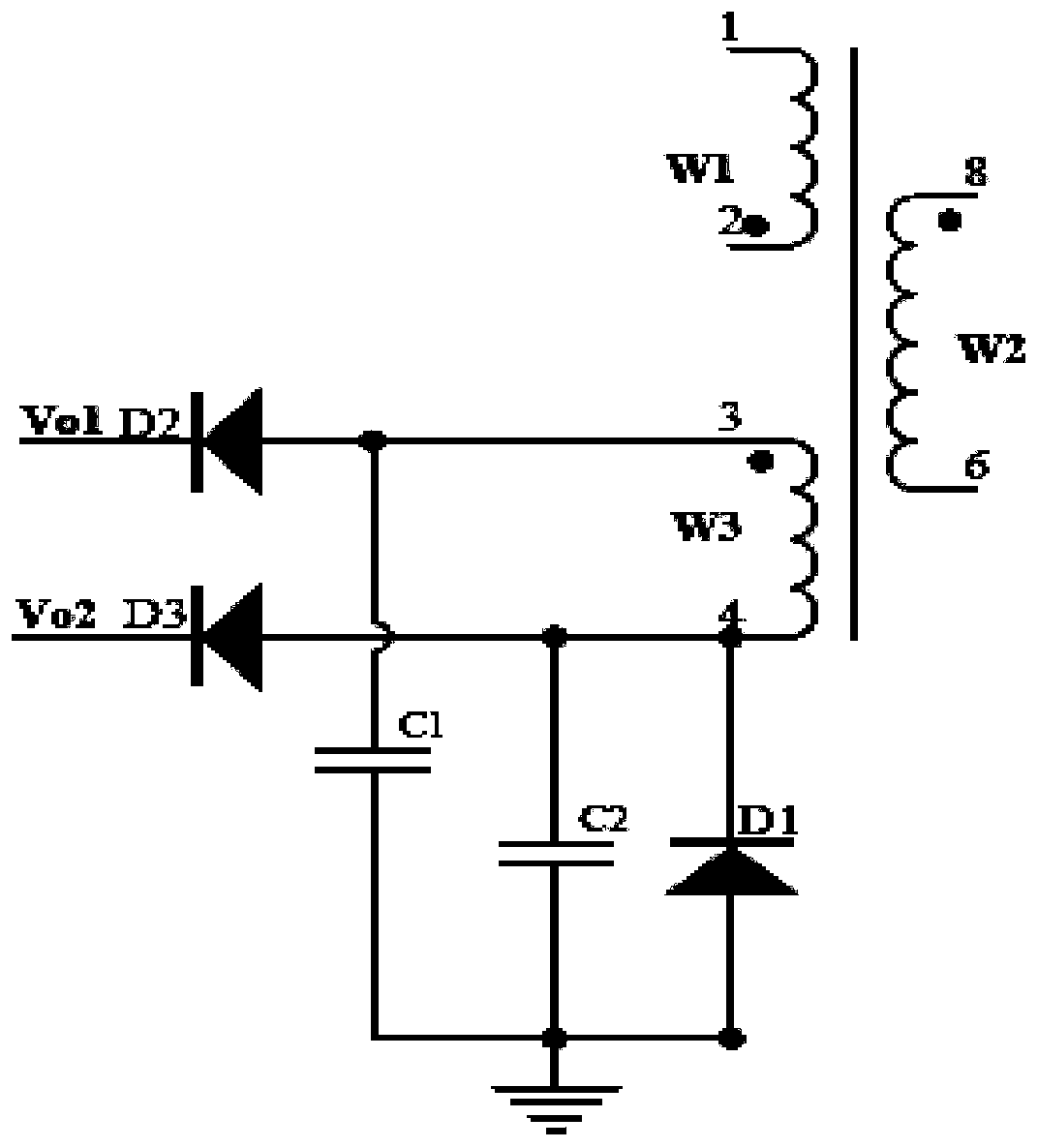

[0039] Such as Figure 5 Shown is the working principle diagram of the third embodiment. Compared with the second embodiment, the difference is that the output terminals of the two voltage stabilizing modules are connected in parallel to output a stable voltage. The working principle of realizing the auxiliary power supply of the forward and flyback windings in this embodiment is the same as that in the second embodiment, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com