Balloon catheter and manufacturing method thereof

A balloon catheter and a technology for making a method are used in balloon catheters, catheters and other directions to achieve the effect of improving passability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

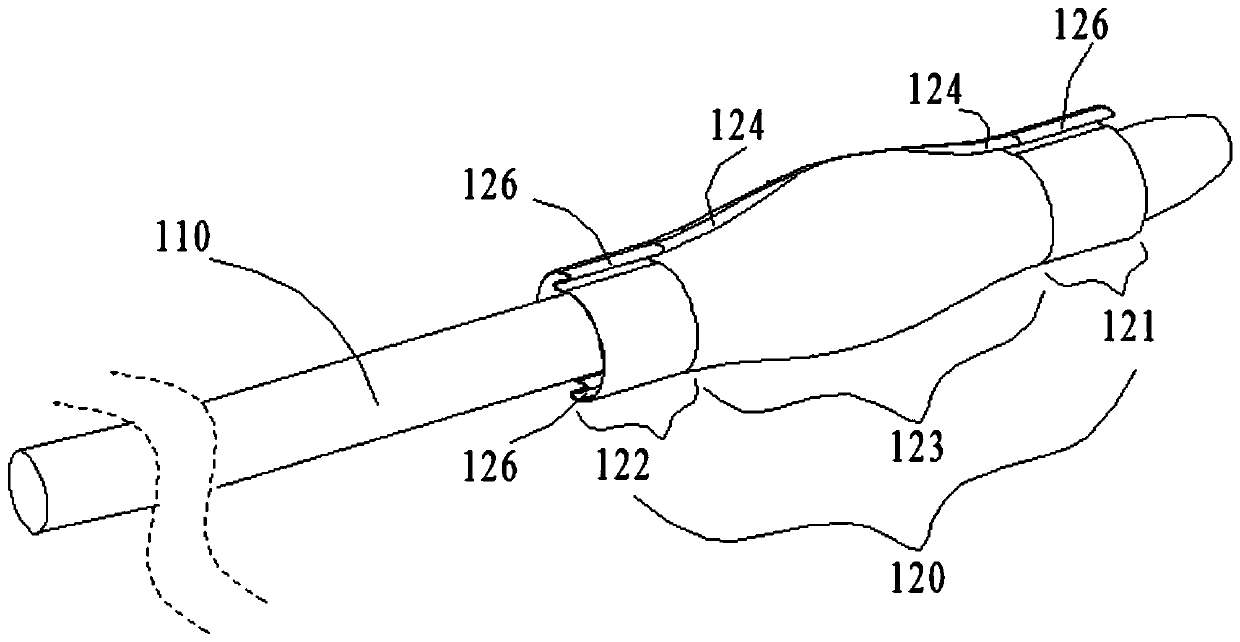

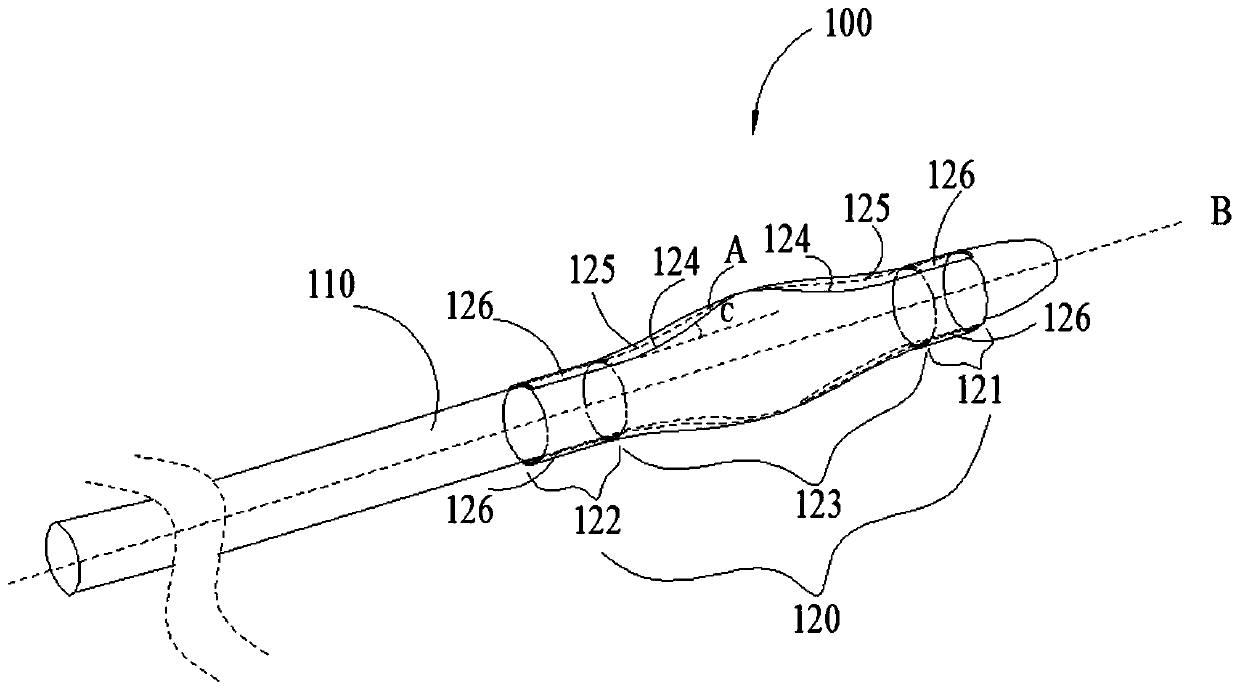

[0042] Example 1 provides a balloon catheter and its manufacturing method, please refer to it together Figure 1-Figure 3 The balloon catheter 100 includes a catheter 110 and a balloon 120 sheathed outside the catheter 110 and located at the distal end of the catheter 110. The catheter 110 is a hollow tube with a certain length, and includes at least one filling cavity for inflating the balloon 120 and at least one guide wire cavity for receiving a guide wire. The distal end of the filling cavity is communicated with the inside of the balloon 120, and the guide wire cavity runs through the entire catheter 110. The balloon 120 is a compliant balloon with a hollow inside and open at both ends, and can also be a semi-compliant balloon or a non-compliant balloon. The balloon 120 includes a first pin 121, a second pin 122, and a balloon 123 located between the first pin 121 and the second pin 122, and the outer diameter of the balloon 123 is larger than that of the first pin 121 and...

Embodiment 2

[0070] The balloon catheter and its manufacturing method of Example 2 are similar to those of the balloon catheter 100 and its manufacturing method of Example 1 above, and will not be repeated here. The main difference lies in that the manufacturing method provided in Example 2 further includes the following steps: S11. After the balloon is sleeved on the distal end of the catheter, the first pin and the second pin are stretched in opposite directions along the axial direction of the catheter. After step S11, the above steps S2 and / or S3 are executed again.

[0071] Or, in other embodiments, the manufacturing method provided in Embodiment 2 further includes the following steps: S38, after fixing the first pin on the catheter, and fixing the second pin or the folded portion of the second pin Before being placed on the catheter, first stretch the second pin along the axial direction of the catheter in a direction opposite to the first pin. After the above steps S1 and S2, a part o...

Embodiment 3

[0077] The balloon catheter of Example 3 and its manufacturing method are similar to those of the balloon catheter 100 and its manufacturing method of Example 1 described above. The main difference lies in that the manufacturing method of the balloon catheter of Example 3 also includes The following steps: after the balloon is sleeved on the catheter, the first pin of the balloon is rotated relative to the second pin in the circumferential direction of the catheter. For example, the two pins can be rotated toward each other at the same time when both pins are not fixed. Or, in other embodiments, one pin can be fixed first, and then the other pin can be rotated along the circumference of the catheter relative to the fixed pin, for example, when the second pin or the folded portion of the second pin is fixed Before being placed on the catheter, the first pin of the balloon is rotated relative to the second pin along the circumference of the catheter.

[0078] You can perform the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com