Proofreading type adhesive dispensing device for electronic manufacturing

A dispensing device and electronic technology, which is applied to the device for coating liquid on the surface, the pretreatment surface, the coating, etc., can solve the problems of inability to check the dispensing position, slow curing speed, low processing efficiency, etc., to improve the solidification. The effect of speed, improving accuracy, and quick proofreading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

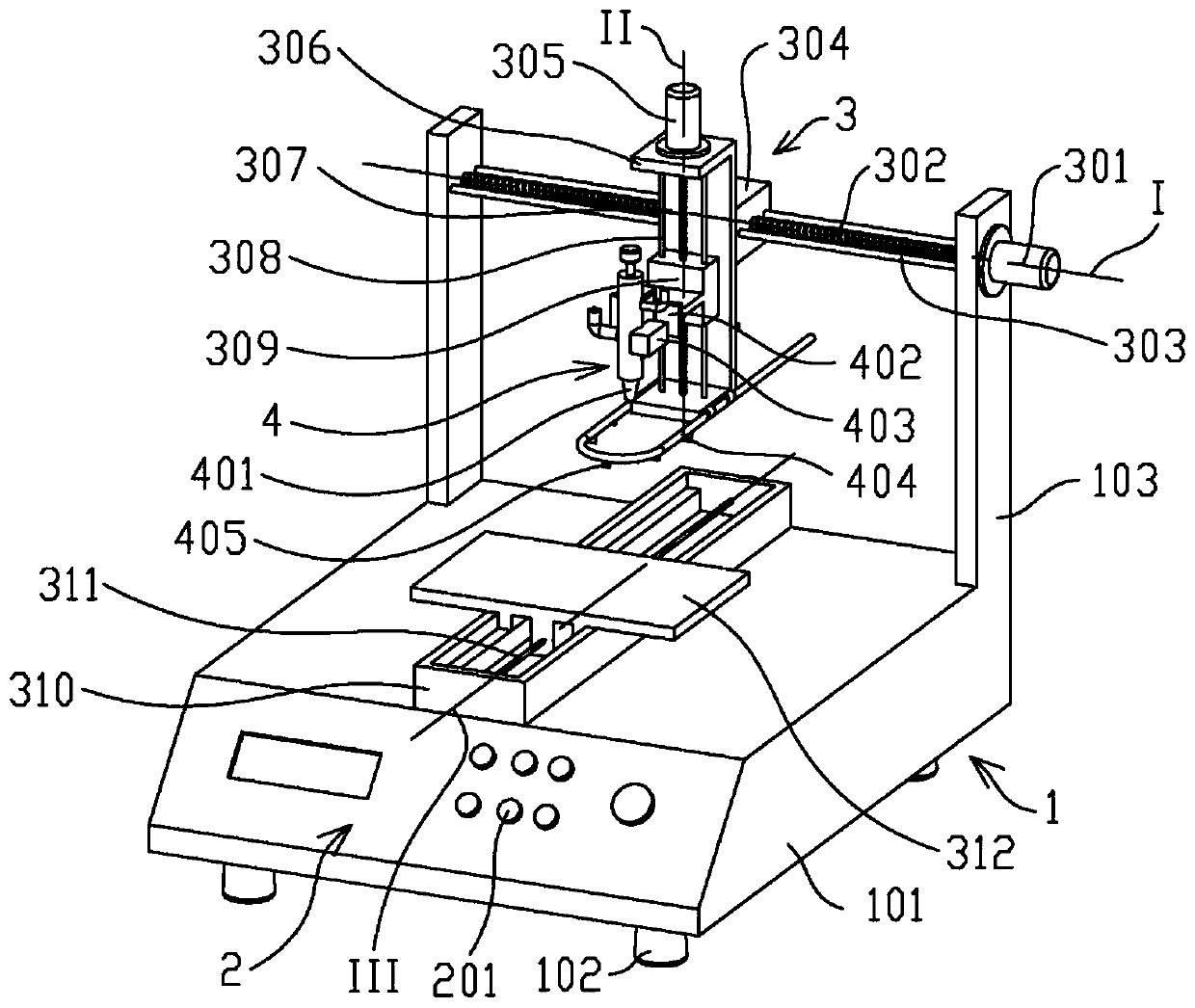

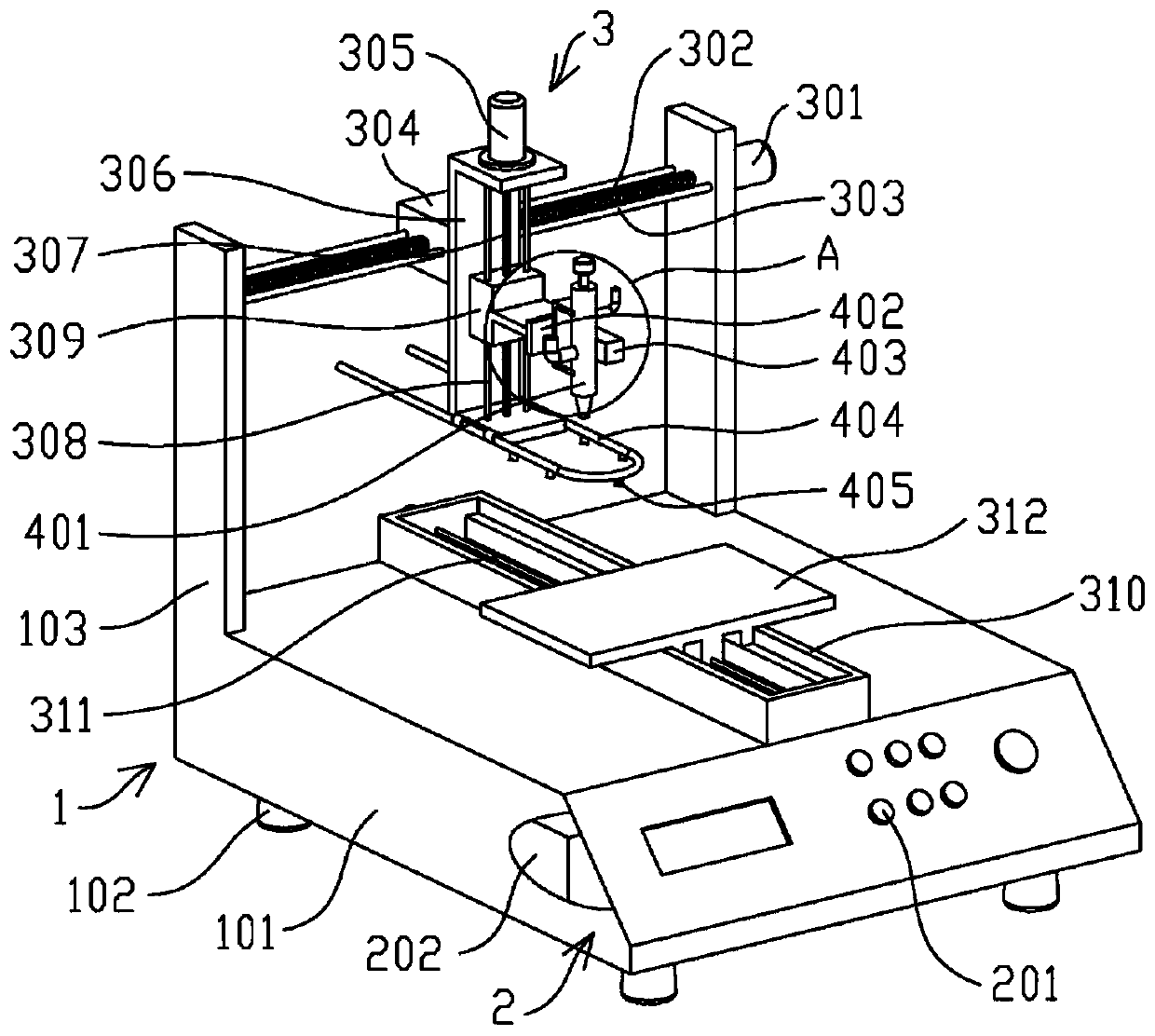

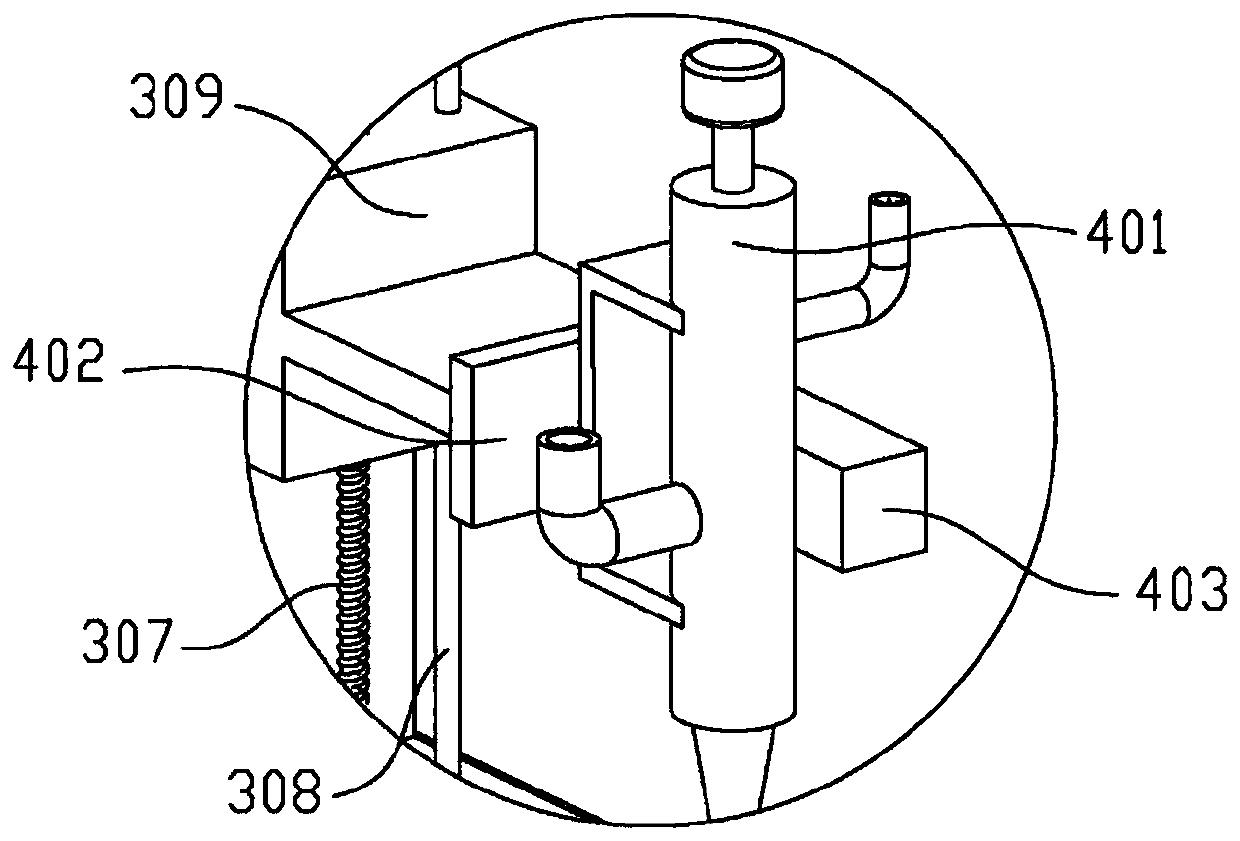

[0045] Such as Figures 1 to 6 As shown, a proofreading dispensing device for electronic manufacturing includes: a fixing mechanism 1 , a control mechanism 2 , a feeding mechanism 3 and a glue dispensing mechanism 4 .

[0046] The fixing mechanism 1 has a base 101, the feeding mechanism 3 has a stage 312 and a second movable block 309, and the dispensing mechanism 4 has a dispensing valve 401 and a dispensing valve 401 arranged on the second movable block 402. The calibrator 403 is used to calibrate the position of the dispensing valve 401 and the workpiece, and the calibrator 403 is fixed on one side of the dispensing valve 401 . The glue dispensing mechanism 4 also has a glue storage cylinder and a glue pump, and the glue in the glue storage cylinder is supplied to the glue dispensing valve 401 through the glue pump. The feeding mechanism 3 can drive the second movable block 309 to move relative to the object stage 312 in space under the control of the control mechanism 2 ,...

Embodiment 2

[0064] The difference from Embodiment 1 is that in this embodiment, the object stage 312 is fixed, and the second movable block 309 moves in a three-dimensional space driven by the feeding mechanism 3, so as to meet the glue dispensing requirements. A specific structure to achieve the above purpose, the feed mechanism 3 can be a three-axis manipulator, for example, a three-axis manipulator is disclosed in the patent text with the application number "201910033805.9", and only the suction cup assembly needs to be replaced with a point The glue mechanism 4 can realize the purpose of spatial movement, so details are not repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com