Contact-type automatic detection device for external thread and thickness

An automatic detection device and thickness detection technology, applied in sorting and other directions, can solve the problems of high labor costs, missed inspections, and sprained hands, etc., to improve competitiveness, avoid product and tool damage, and reduce costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings.

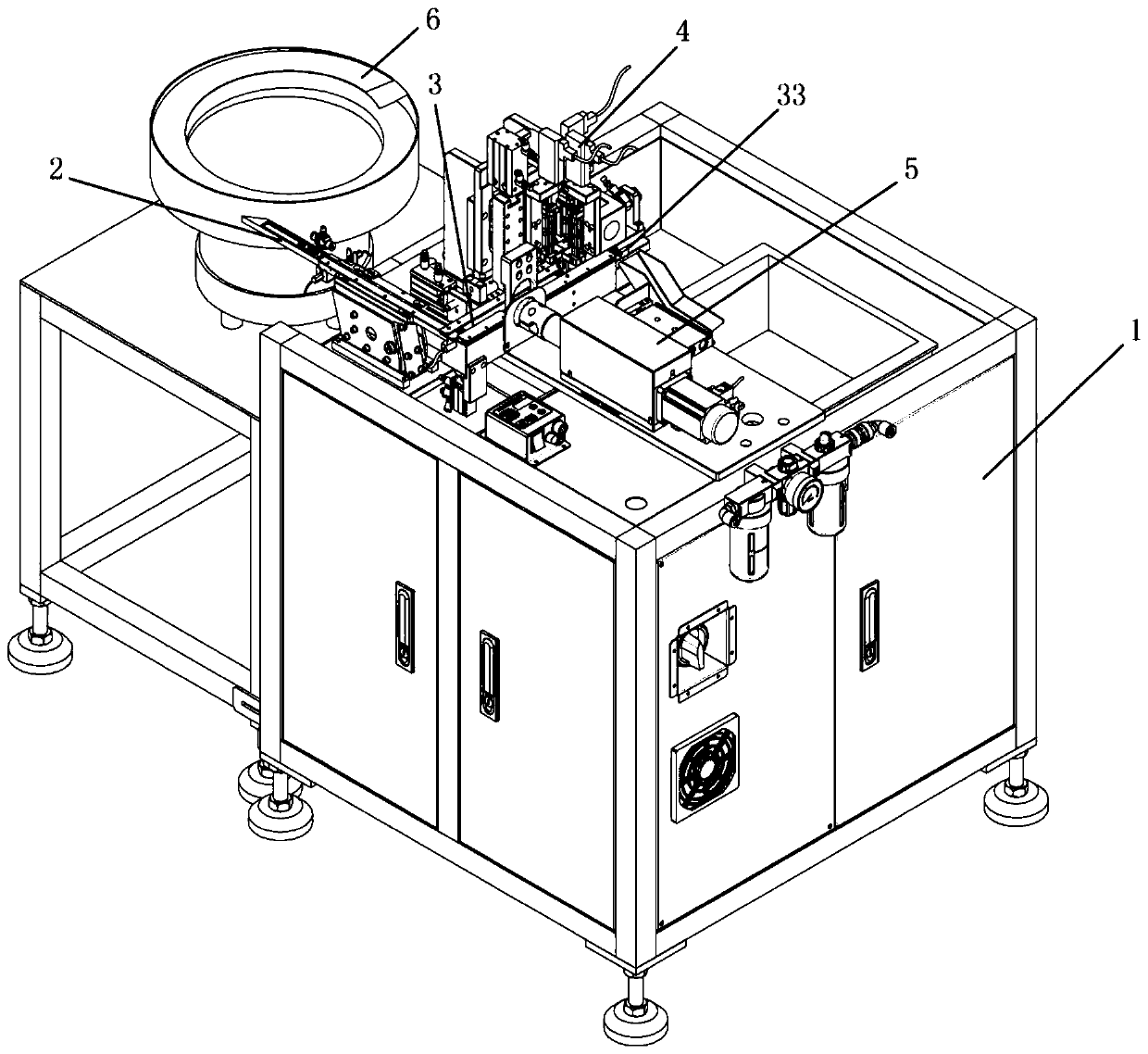

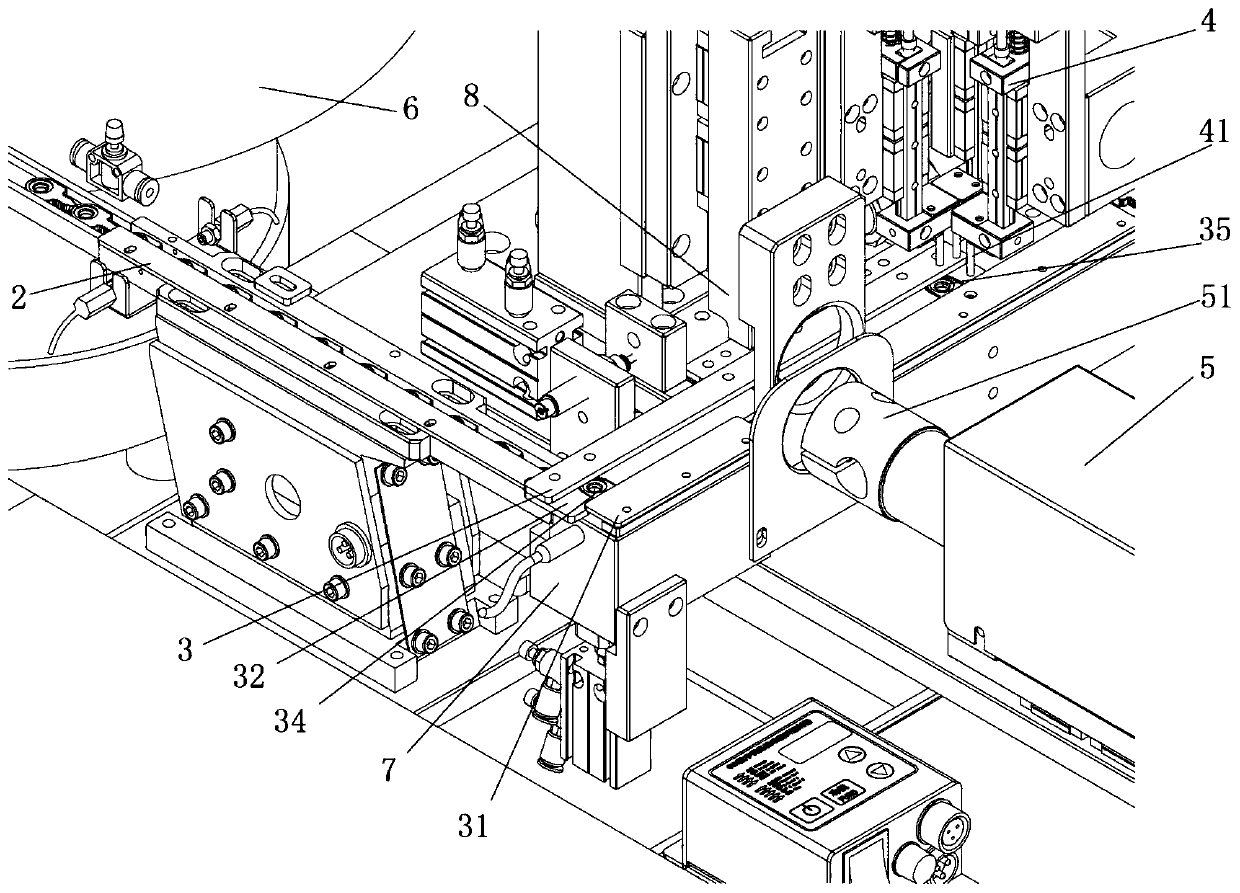

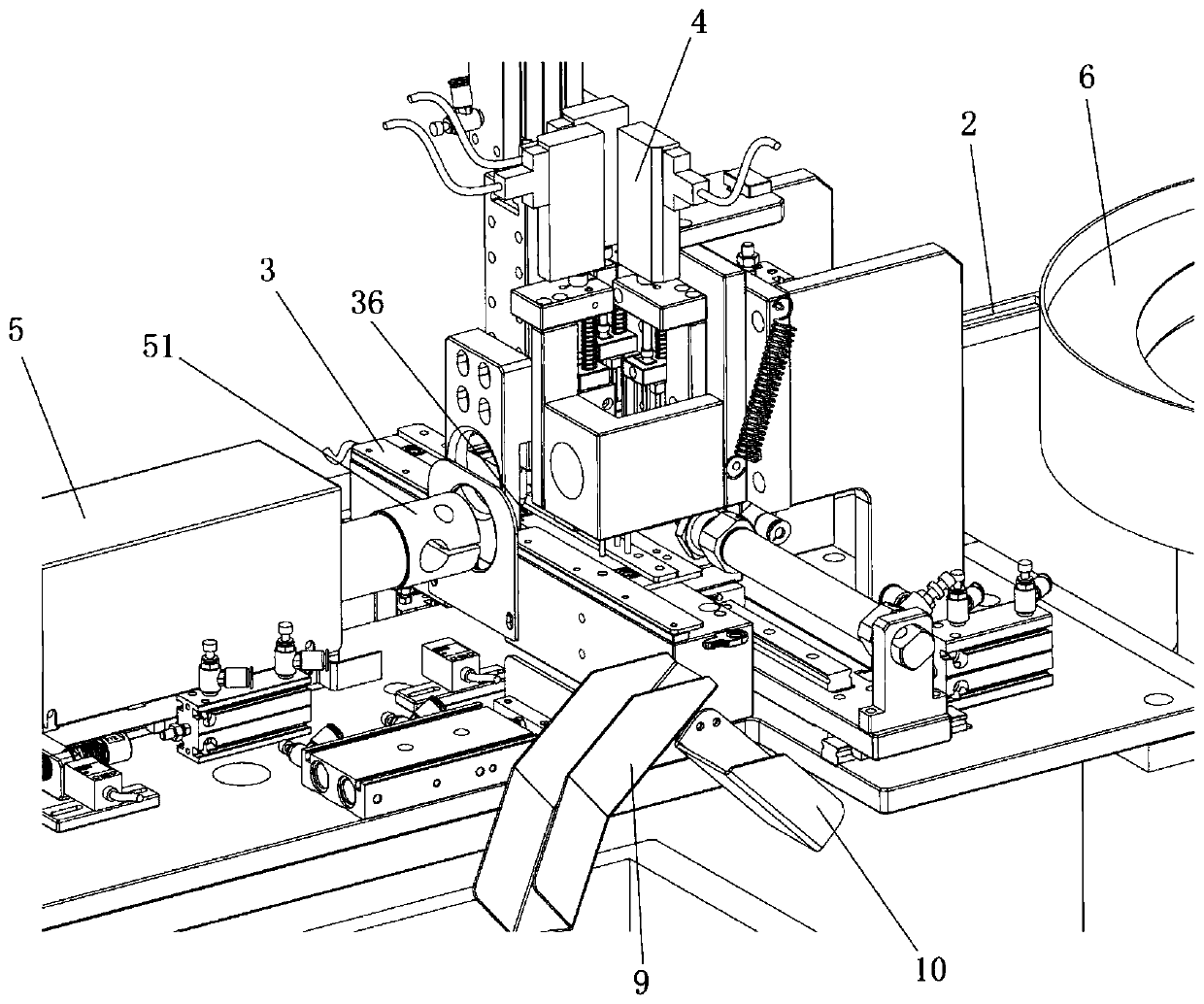

[0037] A contact type automatic detection device for external thread and thickness of the present invention, in its preferred embodiment, please refer to figure 1 As shown in Figure 3, the external thread and thickness contact type automatic detection device of the present invention includes a main frame 1, and a material distribution mechanism, a twisting tooth mechanism 5 and a thickness detection mechanism 4 are installed on the working table of the main frame 1; Distributing mechanism comprises the feeding track 2 machine conveying track 3 that mutually vertically butt joints on the horizontal plane, described feeding track 2 end is docked with the feeding opening of described conveying track 3 front end, and described conveying track...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com