A multi-station hardware machining flanging mold

A technology for flanging molds and hardware, applied in metal processing equipment, forming tools, manufacturing tools, etc., can solve the problems of inconsistent curvature radius at the bending point of plate-shaped parts and excessive heating of the surface of plate-shaped parts.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

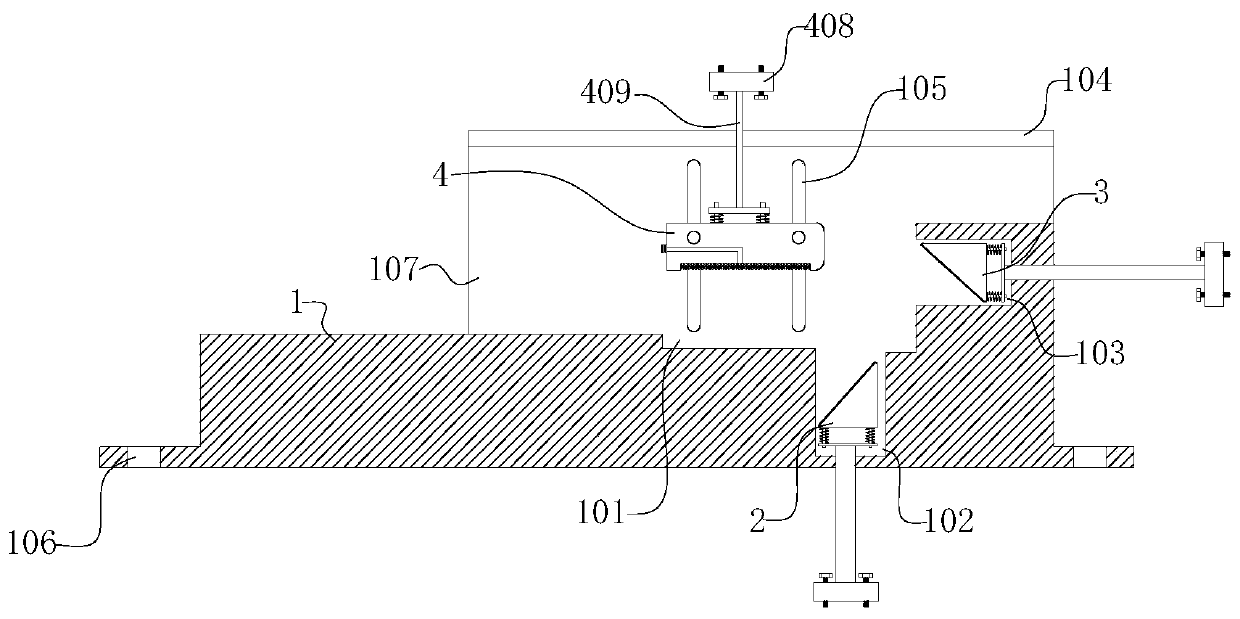

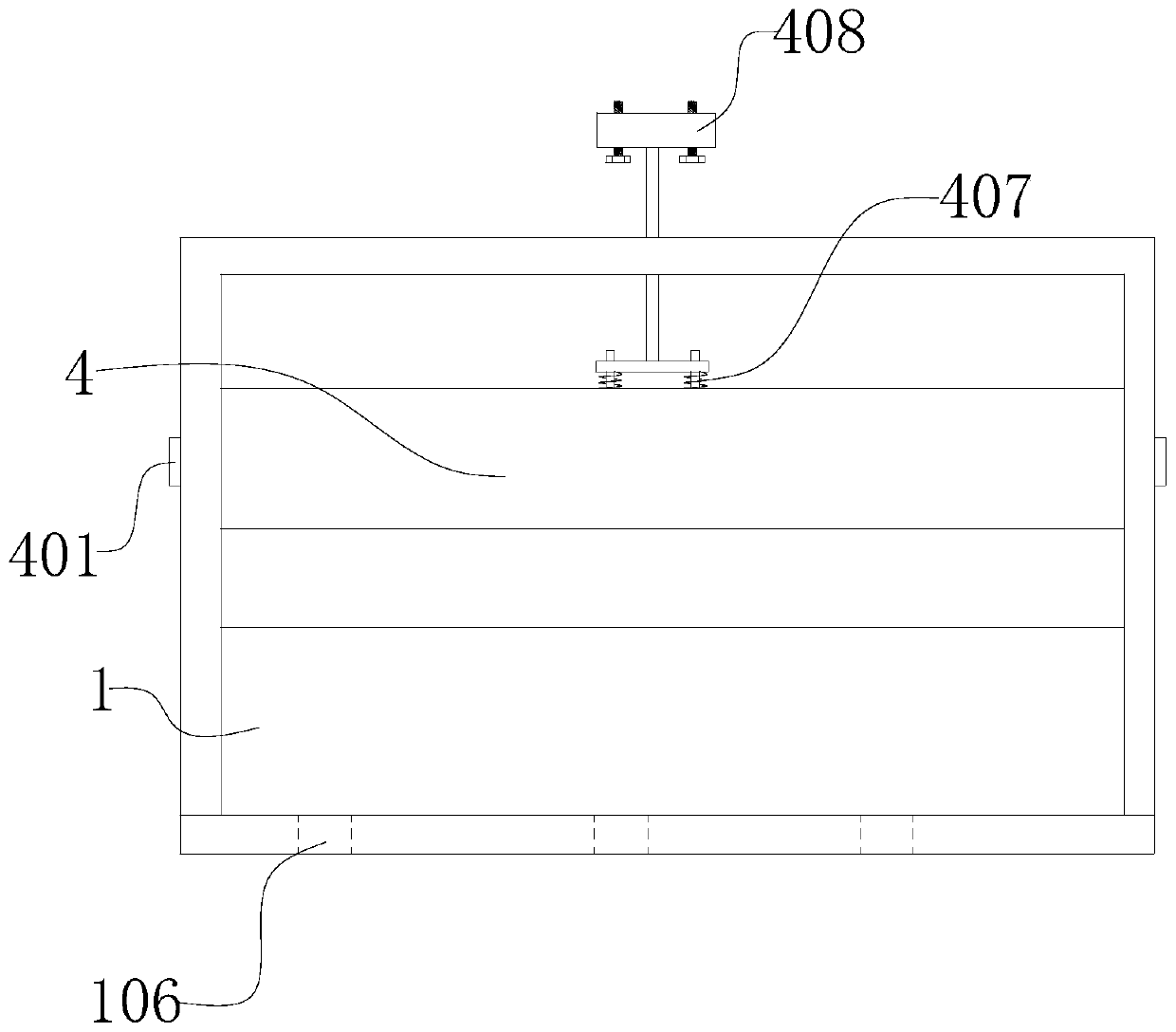

[0033] see figure 1 and figure 2 , is a schematic diagram of the overall structure of a multi-station hardware machining flanging die; including: a lower die base 1, a first punch 2, a second punch 3, an upper die base 4, and the upper die base 4 is set in a square shape Block shape, the two end faces of the upper mold base 4 are provided with bosses 401, and the bosses 401 are set as cylindrical, the upper mold base 4 is arranged above the lower mold base 1, and the lower mold base 1 is set as a square shape, and the square One end of the block is provided with a boss, the two side walls of the lower mold base 1 are provided with support plates, the support plate is provided with a slide hole 105, the top of the support plate is provided with a top support plate, and the boss 401 is embedded in the slide hole 105 ;

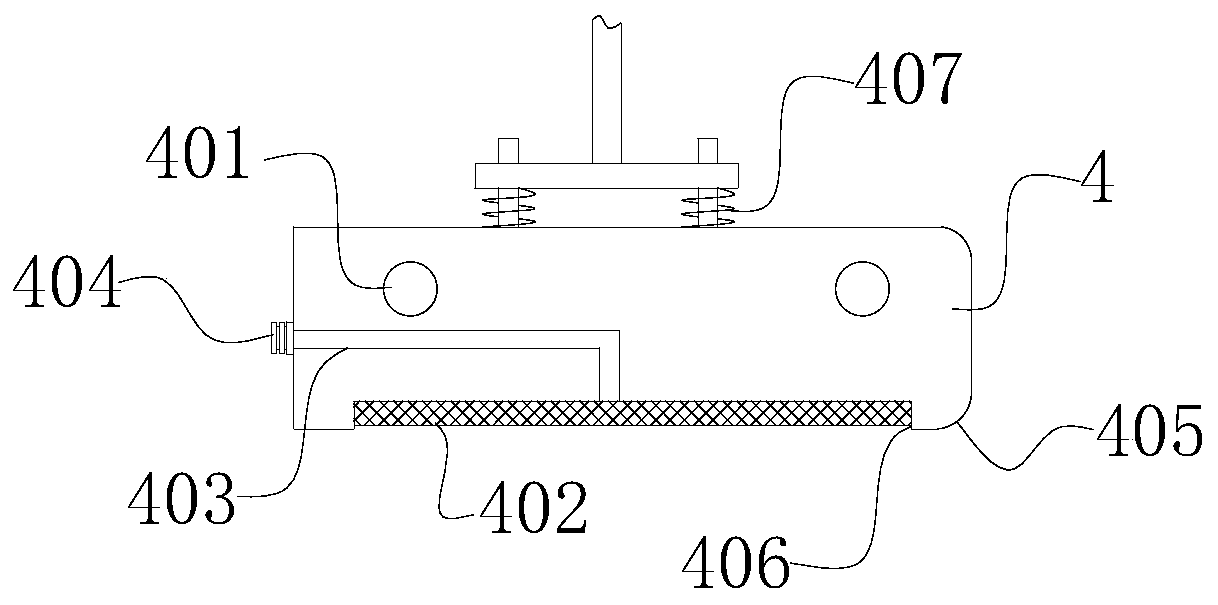

[0034] Wherein, the inside of the upper die base 4 is provided with an oil cavity 403, one end of the oil cavity is connected to the side wall of the upper di...

Embodiment 2

[0043] see Figure 1-5 , is a structural schematic diagram of another multi-station hardware machining flanging mold. This embodiment has the same content as the above-mentioned embodiment 1, and the same will not be described in this embodiment. The specific differences in:

[0044] The top of lower mold base 1 is provided with positioning groove 101, and the contour shape of positioning groove 101 is set as the same as the outer contour shape of hardware, and the bottom of positioning groove 101 is provided with first sinking groove 102, and first sinking groove 102 is made as square Groove, the first punch 2 is provided in the groove of the first sinking groove 102, the side wall of the boss is provided with the second sinking groove 103, the second sinking groove 103 is made as a square groove, and the groove of the second sinking groove 103 is provided with There are 2nd punches 3.

[0045] The first punch 2 is set as a triangular block structure, and the inclined surfa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com