A support method and device for metal additive manufacturing based on conformal substrate

A metal additive and support method technology, applied in the field of metal additive manufacturing, can solve the problems of complex shape and structure of parts, large distance between the support area and the substrate, bending deformation, etc., to achieve strong overall stability, reduce removal strength, The effect of rigid feet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

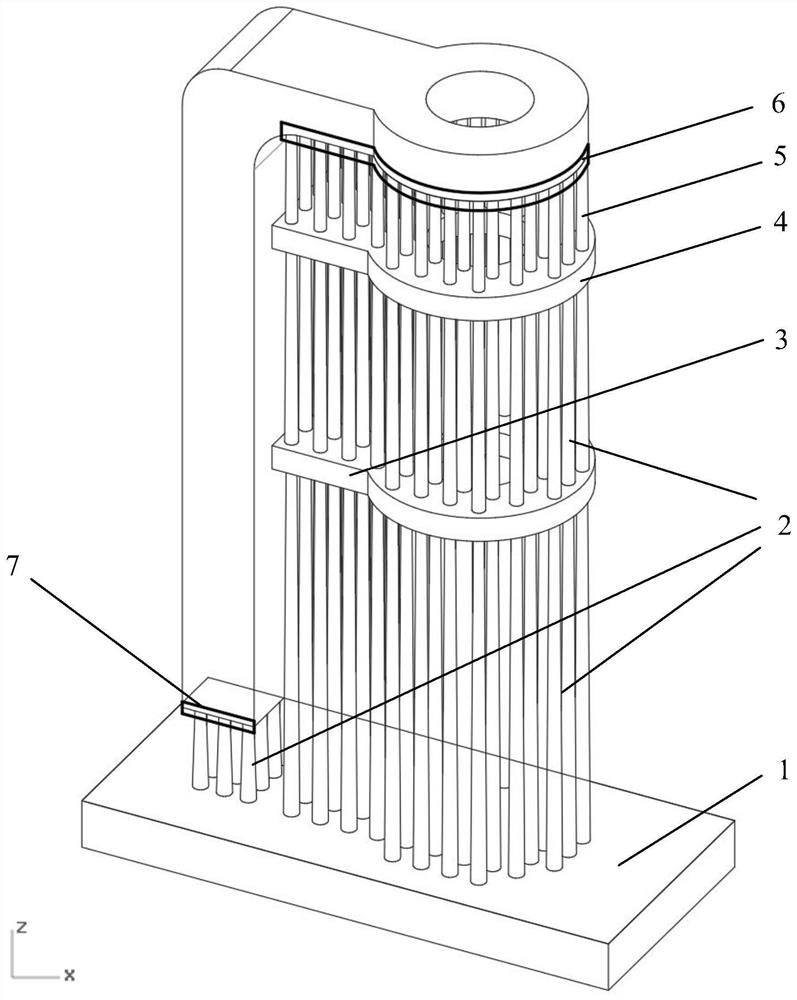

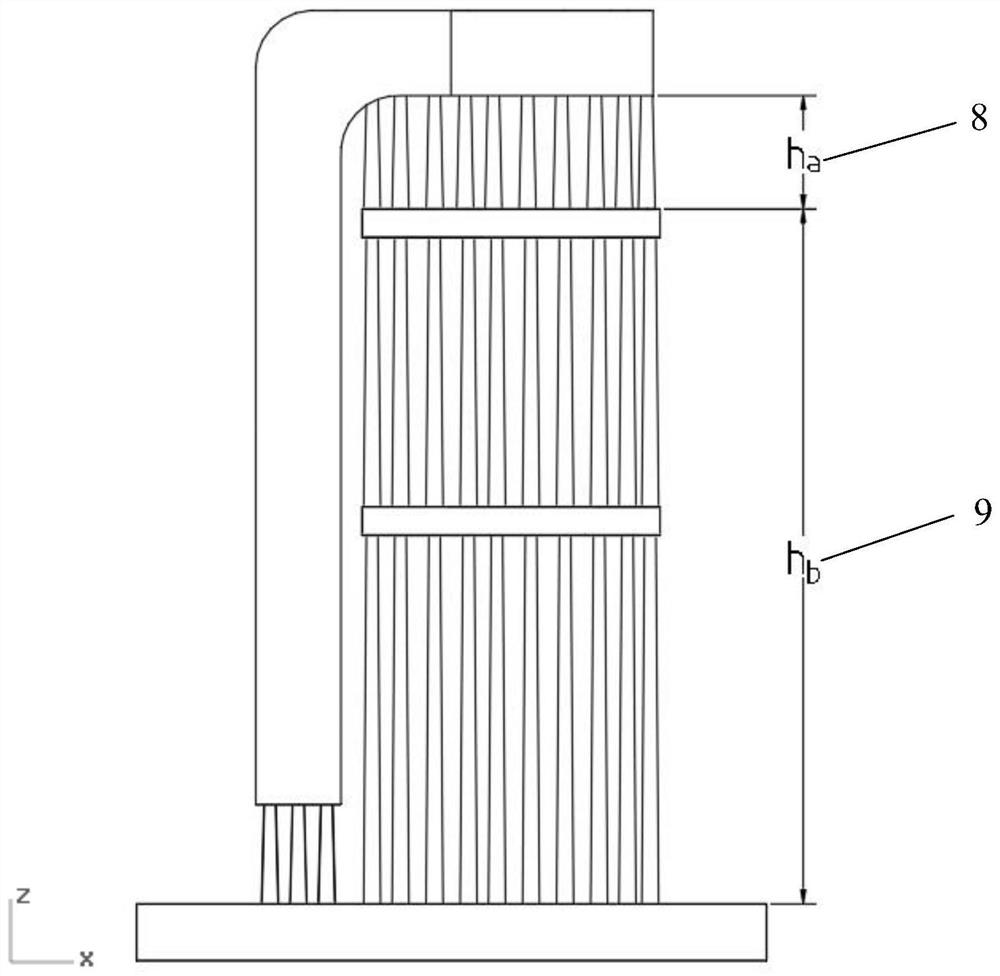

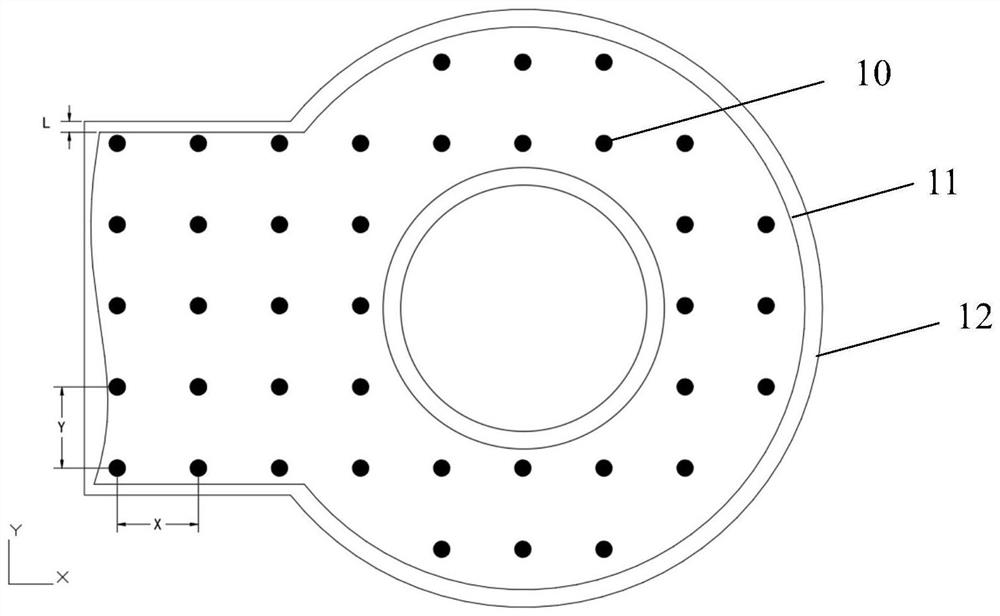

[0040] Refer Figure 1 ~ 6 , A metal additive manufacturing support device based on the posate substrate, figure 1It is shown as a hanging surface with a hole-like structure, and the height of the suspended surface distance is high, and the strength and stability of the part support are increased to ensure the molding quality of the bottom surface and complex structure of the molded part, the present invention is used. A metal additive manufacturing support method based on a conformal substrate. As shown, the fixing substrate 1, the substrate support 2, the apart the auxiliary substrate 3, with the forming substrate 4, the support 5, and the forming substrate support region 6 and the fixed substrate support region 7.

[0041] The present invention is a method of manufacturing a metal additive fabrication based on a conformal substrate, comprising the steps of:

[0042] S1, introduce the three-dimensional model of the molded piece into the MAGICS software. According to the structure...

Embodiment 2

[0053] Refer Figure 5 ~ 10 , A metal additive manufacturing support device based on the posate substrate, Figure 7 A support method of a foil metal additive manufacturing support having a plurality of shapes is illustrated. The metal additive manufacturing support method of Example 2 is substantially identical to Example 1, and the difference is that example 2 is required to design a plurality of support region profiles. The following combination Figure 7 , Figure 8 and Figure 9 The metal additive manufacturing support method of Example 2 is described.

[0054] In conjunction with Example 1, the molded member 18 of Example 2 is in the support region 19, and the support region 20 needs to add a shaped substrate. The support heights 14, 16 of the forming substrate 21 are determined by the MAGICS software, corresponding to the support list. The support area adds a tapered support; determine the total height 15 of the substrate, the substrate support total height 17 determines the num...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com