False twist compact spinning method and device for ring spinning and yarns spun thereby

A ring spinning and false twisting technology, used in spinning machines, textiles and papermaking, drafting equipment, etc., can solve the problems of large energy consumption, compressed air energy consumption, wear and other problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

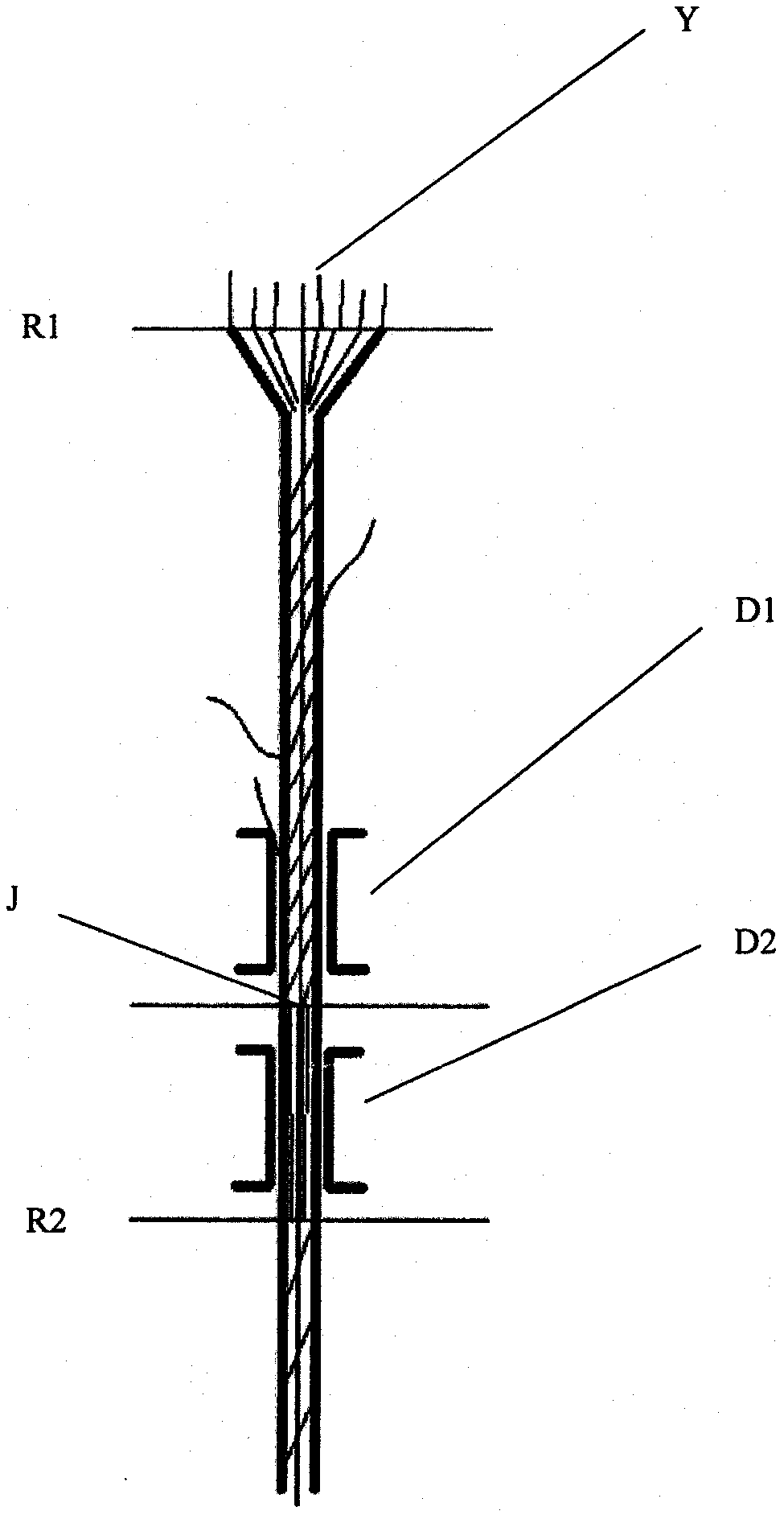

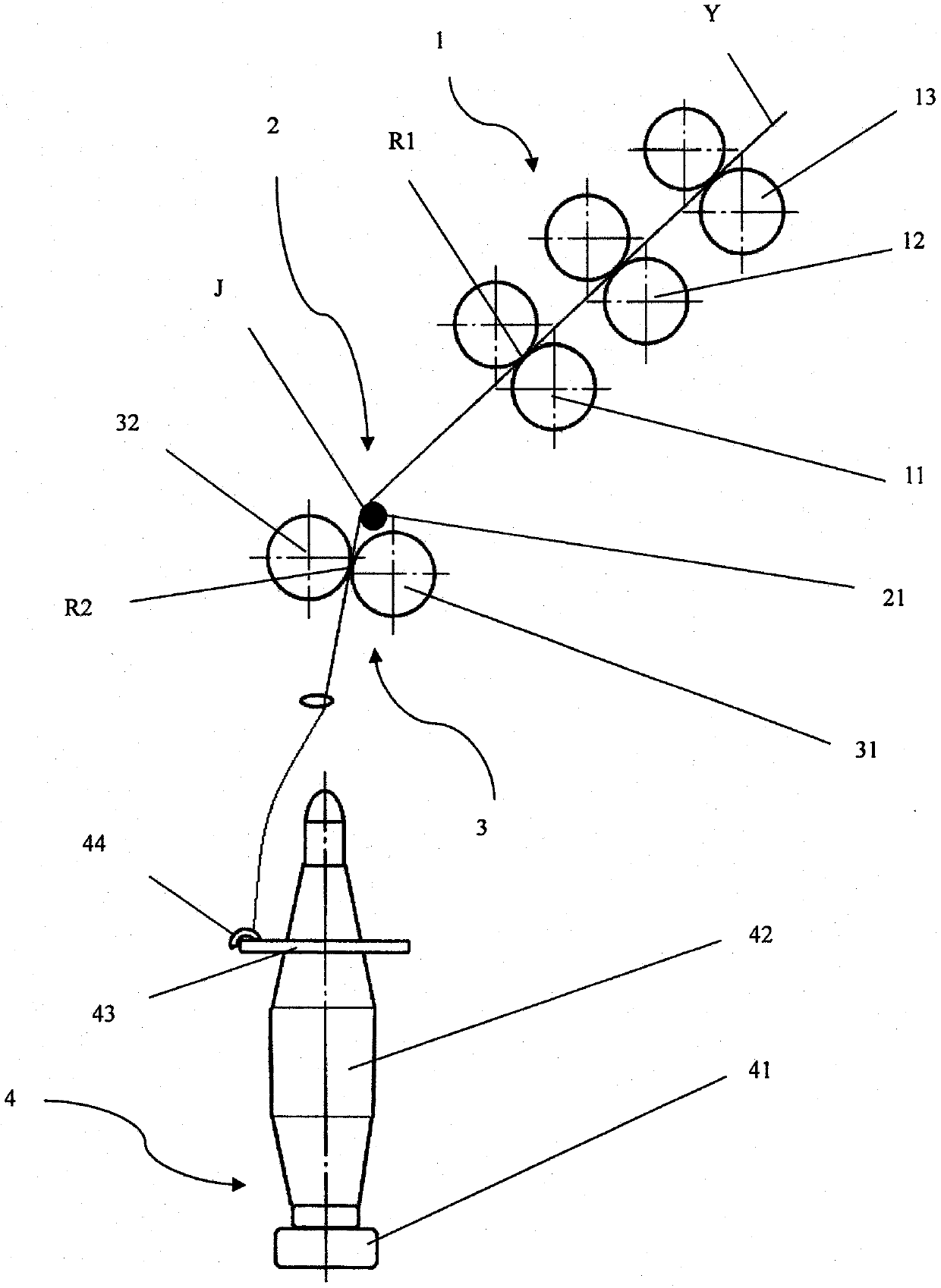

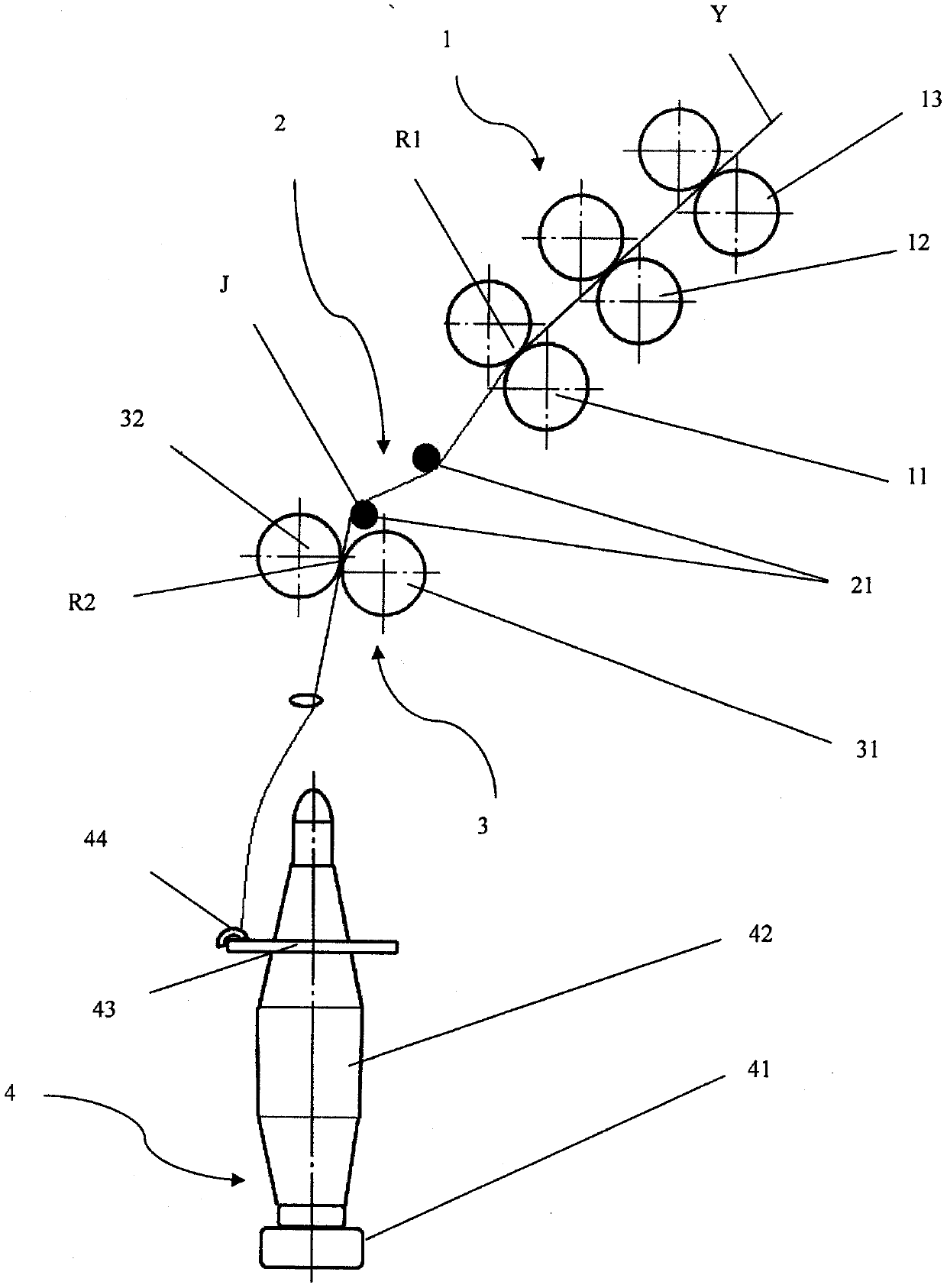

[0030] figure 1 As shown, it is the principle of a ring spinning false twist compact spinning method. A roving Y is drafted by the ring spinning drafting system, and the fiber strands output from the front roller nip R1 are added false twist by the false twisting system. Twisting and twisting, the fiber strands from the false twist point J to the nip of the front roller are twisted, in the shape of yarn, the width of the fiber strands is narrowed and has strong strength, and the yarn guide can be set on the spinning channel D1, the yarn guide channel of the yarn guide D1 has space restrictions on the fiber strands, which can prevent the hairiness existing on the yarn-like fiber strands from diverging outwards, and can play a role in promoting long hairs to wrap around the fiber strands. After the false twist point J, the false twist on the fiber strand recedes, and the fiber strand is pulled by the lead-out roller jaw R2, because the distance between the lead-out roller jaw R2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com