Prefabricated track bed structure of a vibration isolation pad on a bridge

A vibration isolation pad and prefabricated road technology, applied in the field of rail transit, can solve the problems of poor track bed quality, unsuitable bridge structure, slow construction progress, etc., to achieve stable and reliable construction quality, reduce train running vibration, and reduce vertical vibration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] This embodiment provides a prefabricated ballast bed structure with a vibration isolation pad on the bridge;

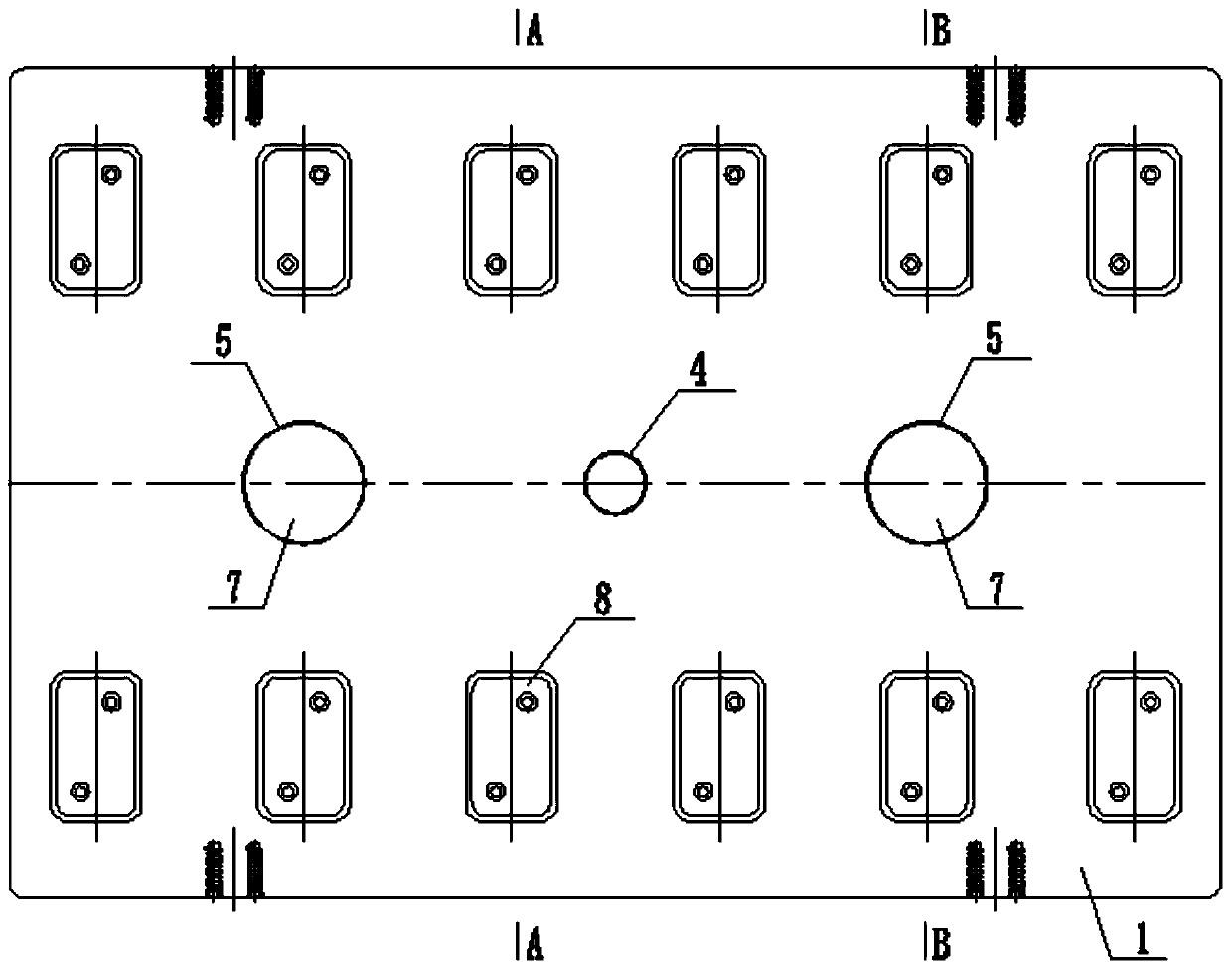

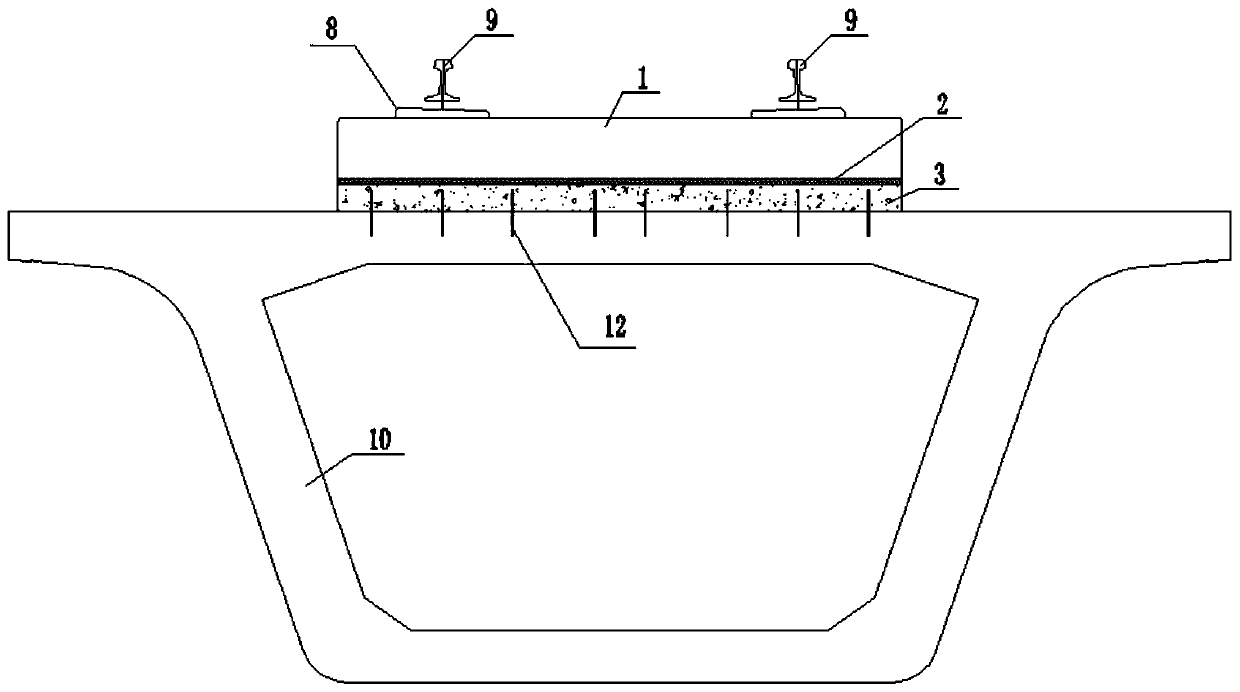

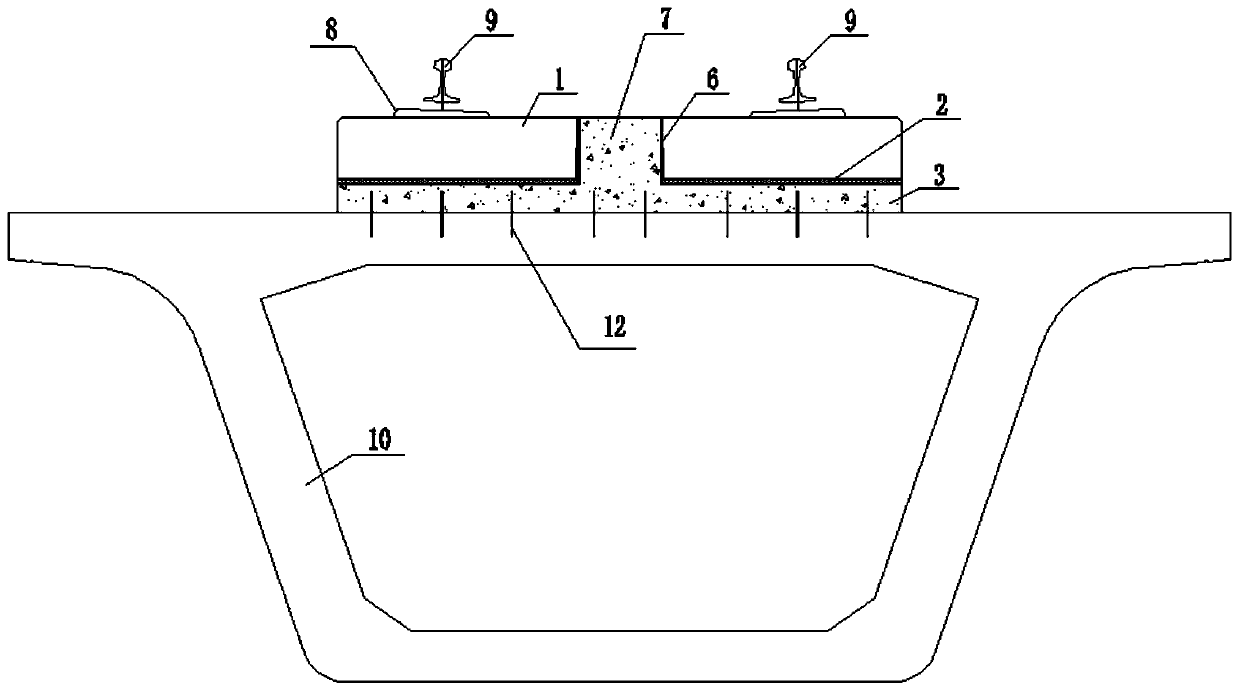

[0046] Such as Figure 1-Figure 6As shown, the vibration isolation pad prefabricated ballast structure on the bridge in this embodiment includes a prefabricated track slab 1 laid on the bridge. prestressed), the prefabricated track slab 1 is fixed with a vibration isolation pad 2, and an adjustment layer 3 is provided between the vibration isolation pad 2 and the bridge surface, and the prefabricated track slab 1 is provided with perforation holes 4 and the limit hole 5, the inner wall of the perfusion hole 4 and the limit hole 5 is provided with an elastic cushion layer 6, and the limit hole 5 is provided with a limit boss 7, and the limit boss 7 is connected to the limit hole 5. The adjustment layer 3 is an integrally formed structure.

[0047] The present invention can effectively reduce the vertical vibration generated when the train is running by setting...

Embodiment 2

[0064] Such as Figure 1-Figure 10 As shown, this embodiment provides a construction method for the prefabricated ballast bed structure of vibration isolation pads on the bridge described in Embodiment 1, including the following steps:

[0065] Step 1. According to the design data, measure and set out the edge line of the prefabricated track slab on the bridge surface. According to the route data provided by the design, the survey team calculates and stakes out the four corners of each prefabricated track slab on the bridge surface, and makes obvious marks. The error of the staked out point is not greater than 5mm, and the edge line of the prefabricated track slab is popped up with ink lines to be laid as steel bars. and prefabricated track slab laying standards.

[0066] Step 2: Gouging and cleaning the bridge surface within the stakeout edge of the prefabricated track slab. For cast-in-place beam surfaces and prefabricated bridge surfaces that are not chiseled, chiseling t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com