Tiling robot and tiling method

A technology of robots and ceramic tiles, which is applied in the direction of architecture and building construction, can solve the problems of insignificant improvement of work efficiency, shortening of building decoration progress, and low overall work efficiency, so as to achieve high-efficiency actions, realize recycling, and improve The effect of utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

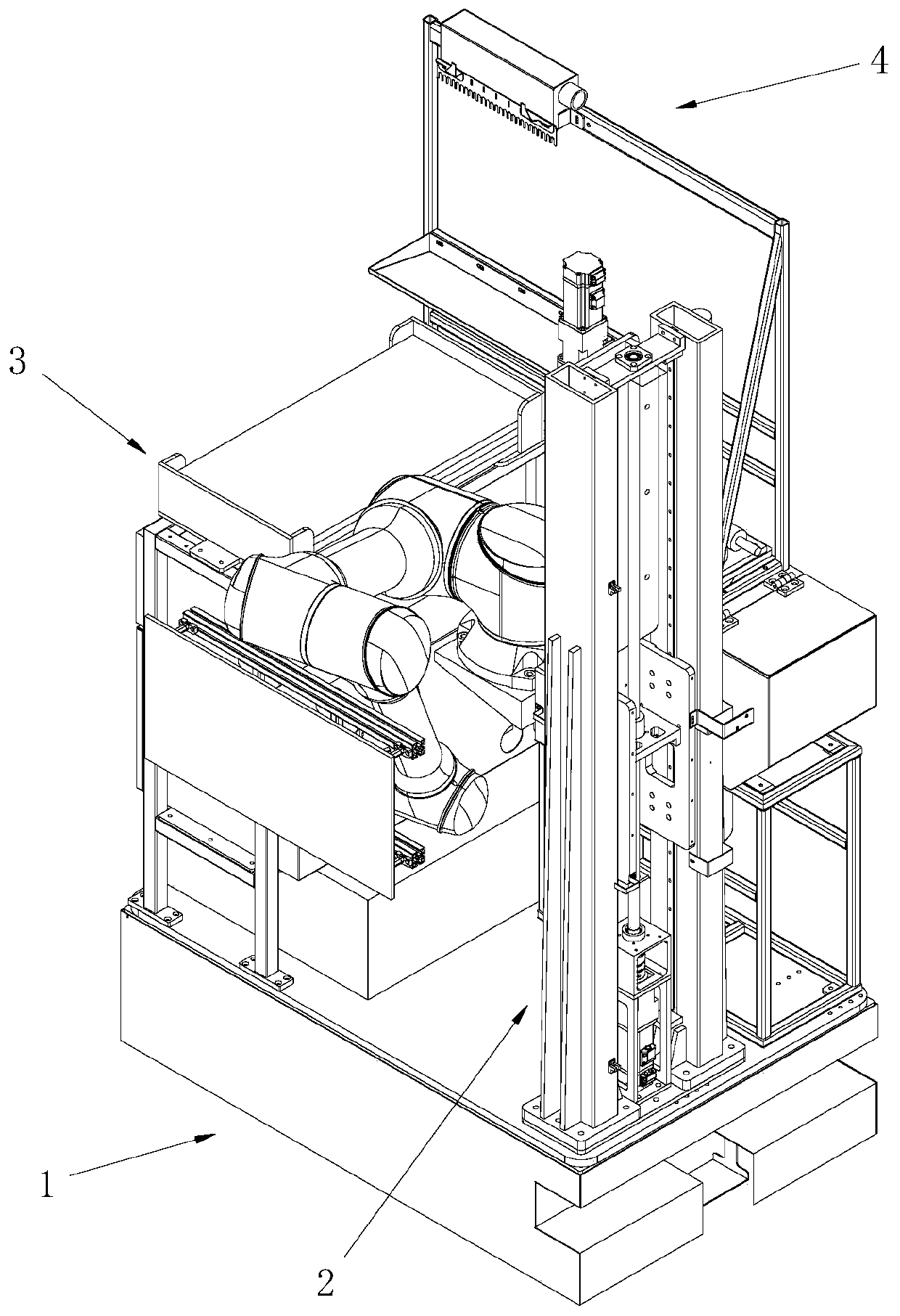

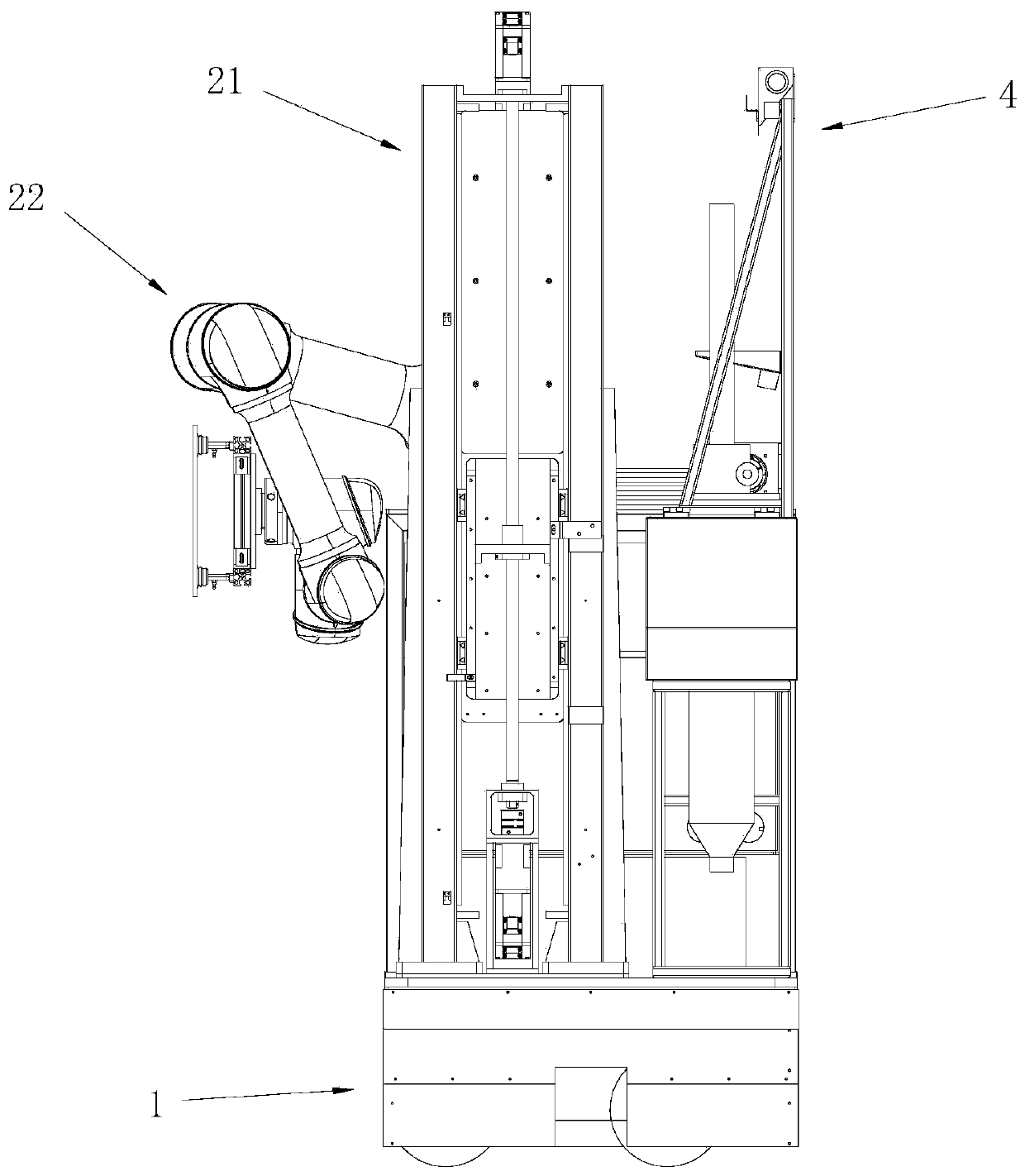

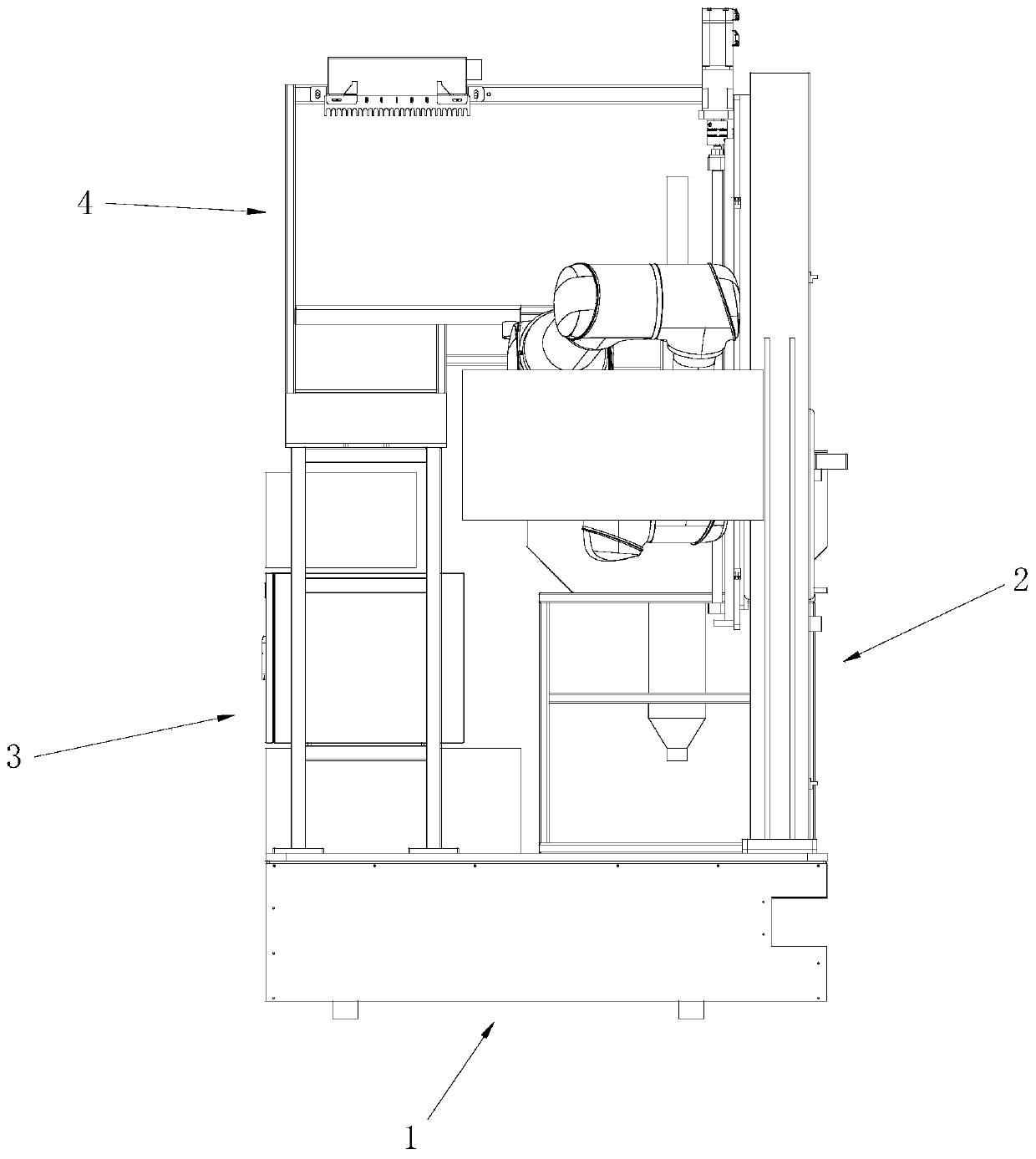

[0081] like Figure 1 to Figure 7 As shown, a tile laying robot includes a walking chassis 1 , a laying mechanism 2 , a tile placing frame 3 and a brushing mechanism 4 . The walking chassis 1 is configured to drive the overall movement of the robot. The first side 11 of the walking chassis 1 is a vacant area. During the tile laying process, the first side 11 of the walking chassis 1 is close to the building surface to be laid. The two sides 12 are adjacent to the first side 11 . The paving mechanism 2 is arranged on the second side 12 of the walking chassis 1, and is located at an end of the second side 12 close to the first side 11, and is configured to grab and transfer tiles to be laid. The tile placing frame 3 is mounted on the third side 13 of the walking chassis 1 and is configured to stack tiles to be laid. The brushing mechanism 4 is installed on the fourth side 14 of the walking chassis 1 and is configured to paint the tiles to be laid with adhesive.

[0082] The p...

Embodiment 2

[0095] The difference between this embodiment and Embodiment 1 is that the brushing mechanism further includes a linear slider, which is arranged on the upper cross bar of the upper support frame, and the brushing actuator is slidably connected with the upper support frame through the linear slider. The brushing actuator moves relative to the lifting device. During the painting process, the paving manipulator is stationary, and the brushing actuator moves linearly to achieve the coating of the adhesive.

Embodiment 3

[0097] A tile laying method, comprising the following steps:

[0098] S1. The walking chassis drives the tile placement rack, paving mechanism and brushing mechanism to move to the work station;

[0099] S5. Obtain the position information and inclination information of the walking chassis, position the paving mechanism through the position information, and perform positioning compensation adjustment on the paving mechanism through the inclination information;

[0100] S10, the paving mechanism grabs a tile from the tile placement rack;

[0101] S20. The paving mechanism transfers the tiles to the brushing mechanism, and the brushing mechanism paints the bonding material on the sticking surface of the tiles;

[0102] S30. The paving mechanism directs the painted tiles towards the building surface to be paved, and the paving mechanism pastes the tiles on the building surface to be paved;

[0103] S40. Judging whether the construction surface in the current work station has be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com