Movable clamped anti-shock bracket and clamping sleeve combined part special tool

A technology of anti-seismic support and special tools, applied in the direction of pipes/pipe joints/fittings, pipe components, electrical components, etc., to achieve the effect of improving anti-seismic stability and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

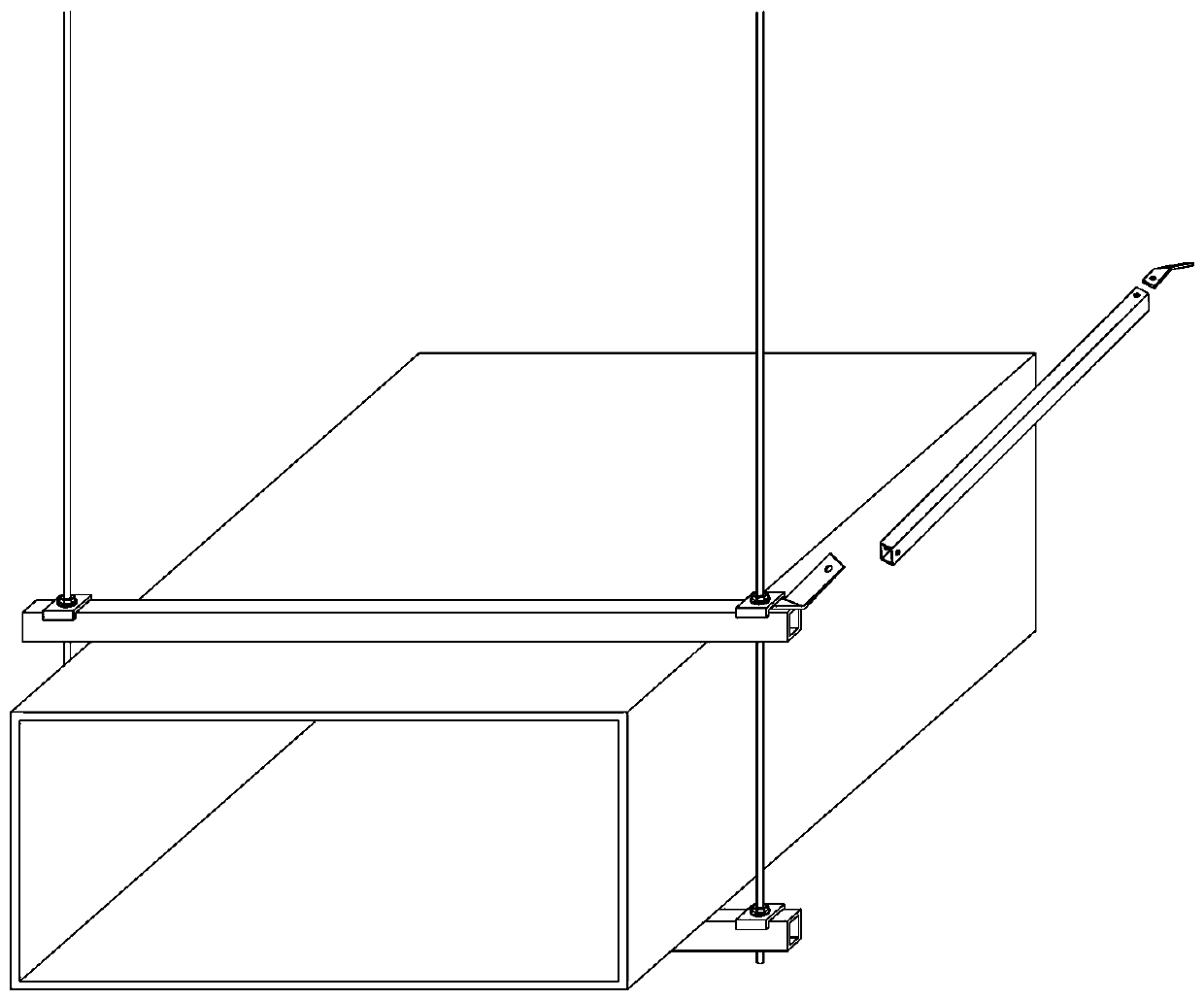

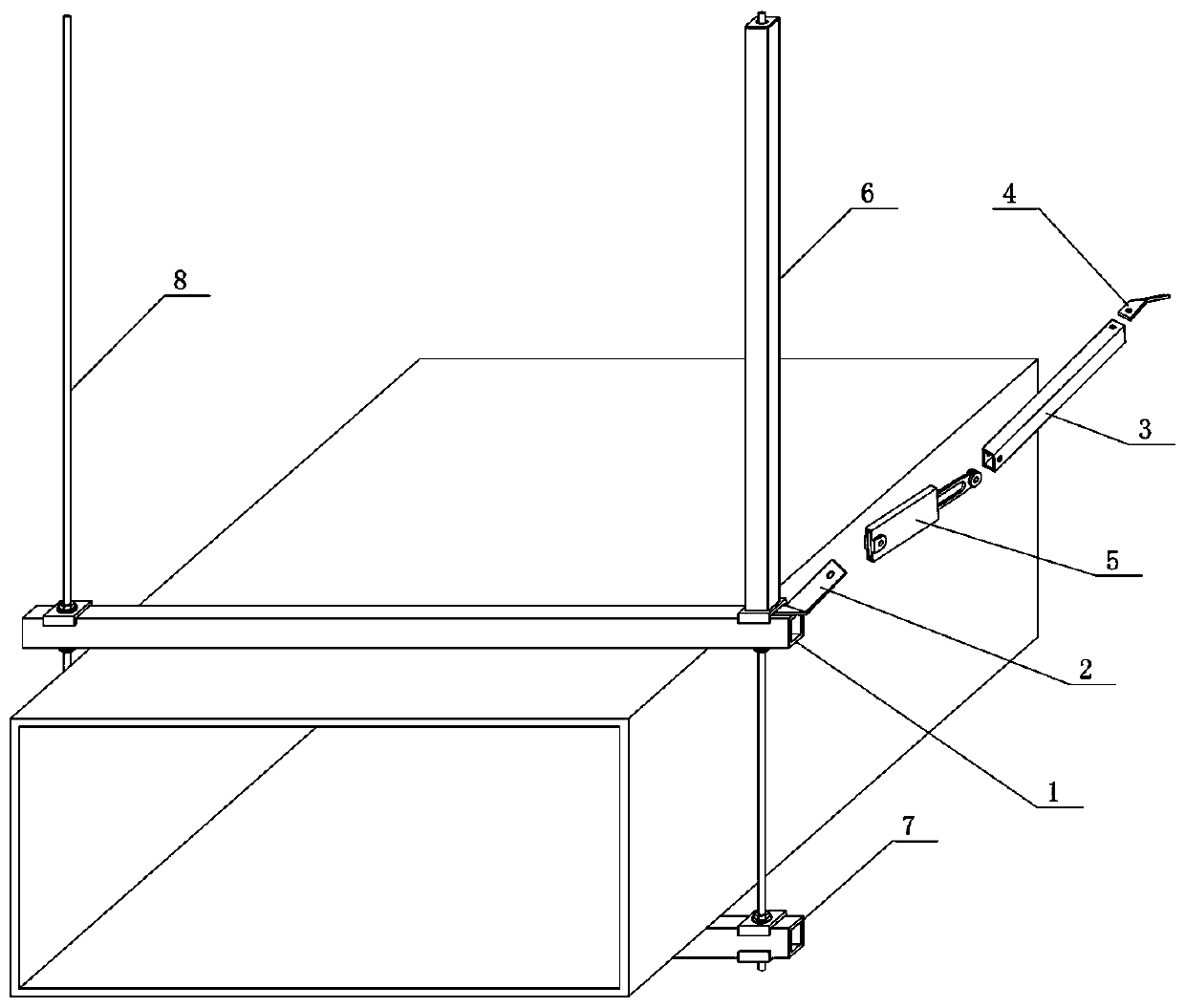

[0039] Embodiment 1: A movable clamping anti-seismic support such as figure 2 As shown, it includes a single support beam or connects auxiliary parts 7 etc. at the lower part of the support beam. There are suspenders 8 at both ends of the supporting beam 1. Usually, holes are drilled in the ceiling directly above the beam and expansion sleeves are installed. The suspenders are full-threaded screws. The upper end is threaded with the expansion sleeve, and the lower end is threaded with the end of the supporting beam. . The drawbars are scattered on the left and right sides or the outside of the end of the support beam, and usually there are multiple drawbars. Such as figure 2The lower end of the drawbar 3 is connected to the end of the support beam through the bottom corner connector 2, and the upper end of the drawbar is fixedly connected to the ceiling through the top corner connector 4 through the expansion wire.

[0040] compared to figure 1 Prior art connection mode,...

Embodiment 2

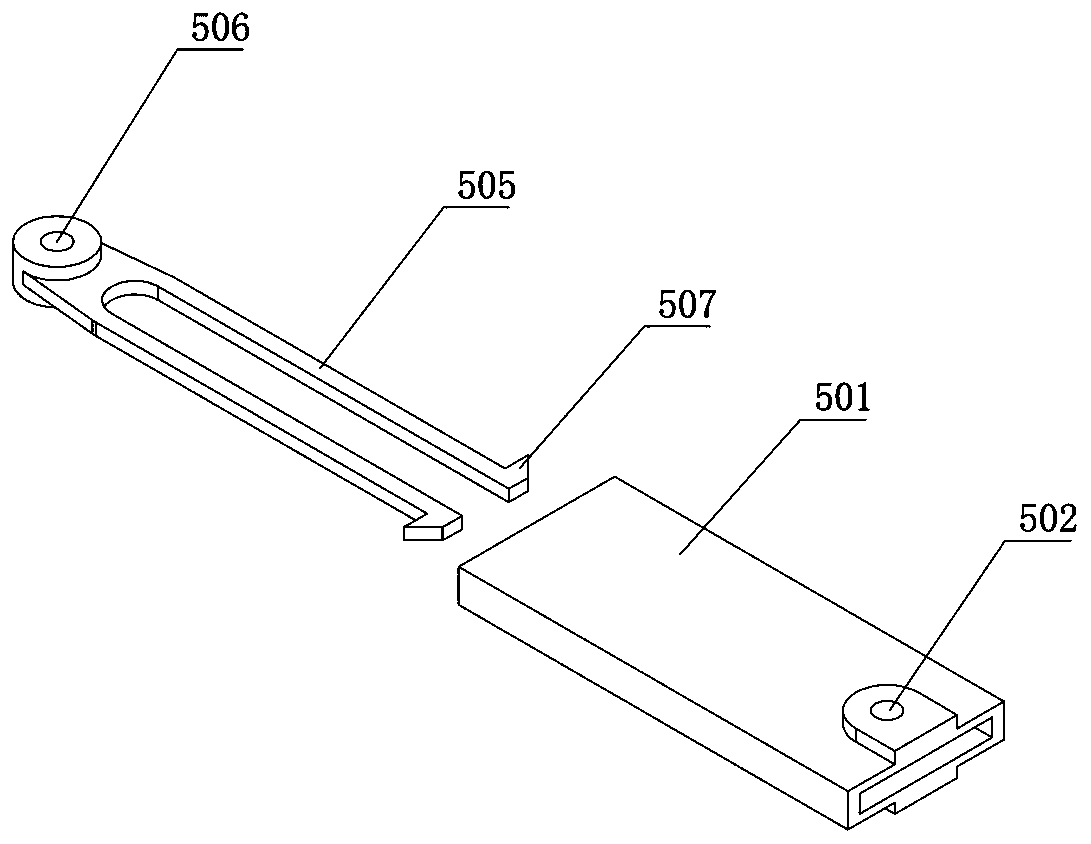

[0042] Embodiment 2: This embodiment improves the ferrule assembly on the basis of Embodiment 1. Specifically, a toothed rack 508 is formed on the outer side of the two fork levers of the card joint, such as Figure 6-Figure 8 As shown, setting the rack on the outside of the two-fork lever can utilize a jig or a special tool to press the rack to force it into the sleeve.

[0043] For example, using Figure 9-Figure 13 The special tool shown, the special tool includes an I-shaped bracket, a fixed side shaft is vertically connected between the two side wings of the I-shaped bracket, a rotating sleeve is set on the outside of the fixed side shaft, and a horizontal rotation shaft is vertically connected to the side of the rotation sleeve, and the horizontal rotation shaft Gears are set on the upper sleeve, and a drive plate is set on the horizontal shaft at the same time. The drive plate and the gear are fitted and fixed, and the drive plate is connected with a handle. A gear ho...

Embodiment 3

[0045] Embodiment 3: another kind of movable clamping anti-seismic support, embodiment 1 has given the current such as figure 2 The installation structure of the anti-seismic bracket is shown, but this embodiment is also suitable for adopting a prestressed structure with multiple rods repelling each other. For example, put figure 2 The suspender in the suspension rod should be a support rod hinged up and down, that is, the upper end is hinged with the upper connecting piece through the pin shaft, the upper connecting piece is fixed on the ceiling through the expansion wire, and the lower end is hinged with the lower connecting piece through the pin shaft, and the lower connecting piece is fixed on the support end of beam. Or at the same time, a jacket support tube is sleeved on the outside of the support rod. The left and right symmetrical positions and the outer positions of the support rods or the overcoat support tubes are respectively connected as follows: figure 2 E...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com