Magnetic powder flaw detecting trolley with additional axle inspection function for axle flaw detector

A technology of magnetic particle inspection and flaw detection machine, which is applied to the cleaning methods of tools, conveyors, mechanical conveyors, etc., can solve the problems of multiple steps and time of magnetic particles, inability to add and store magnetic particles, low efficiency, etc., and achieves safe and convenient use. , Easy to add and store, scientific and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

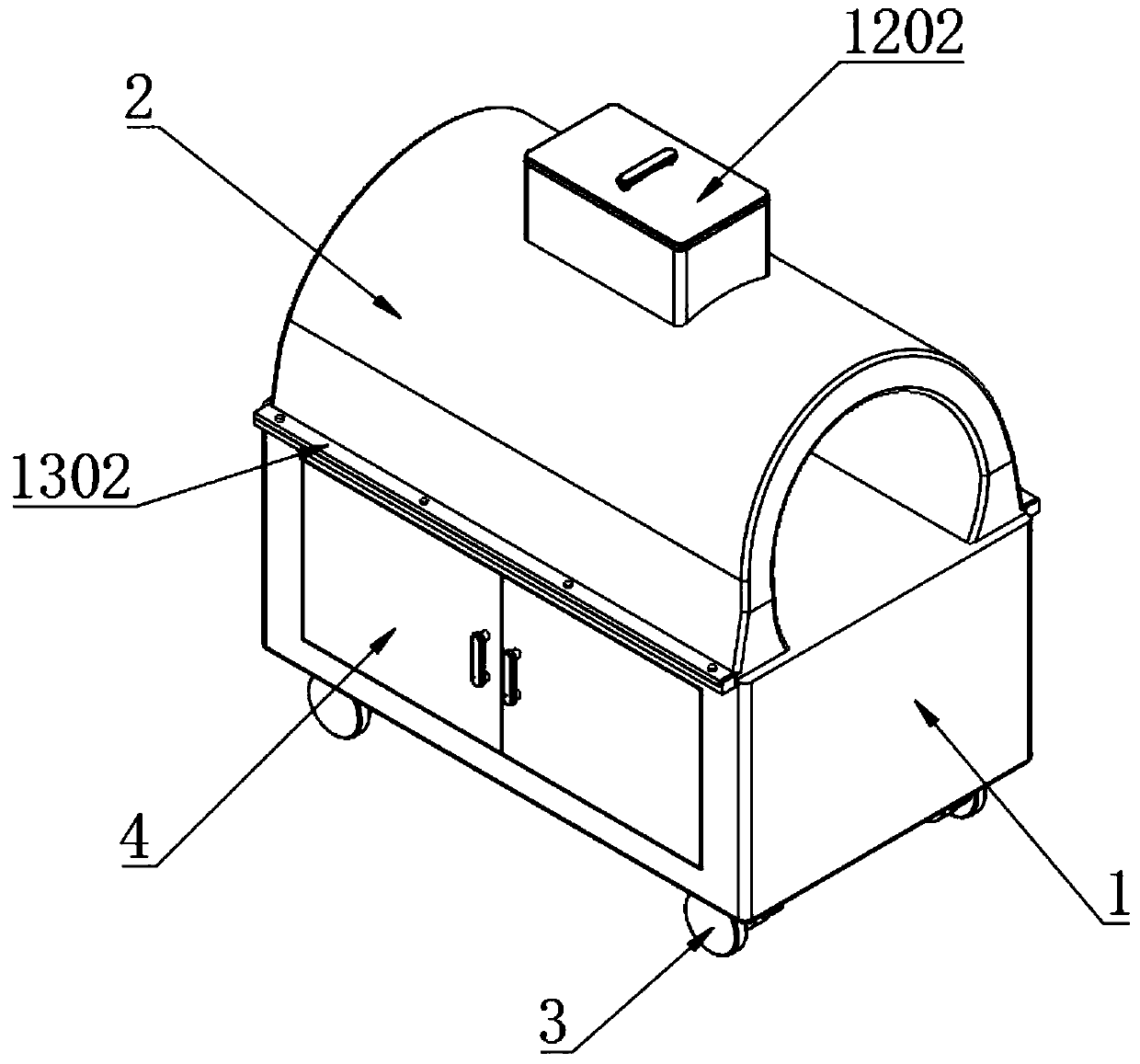

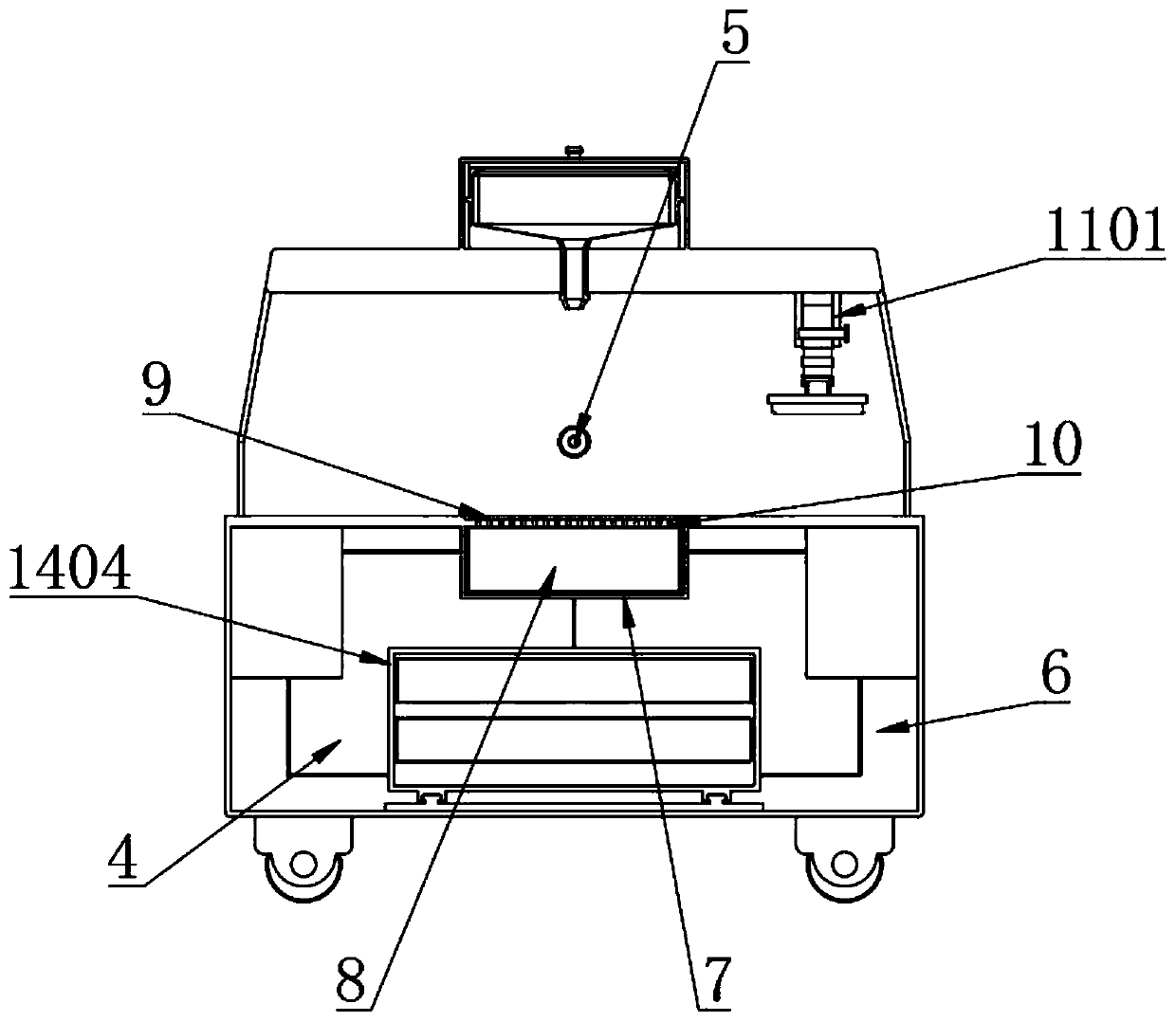

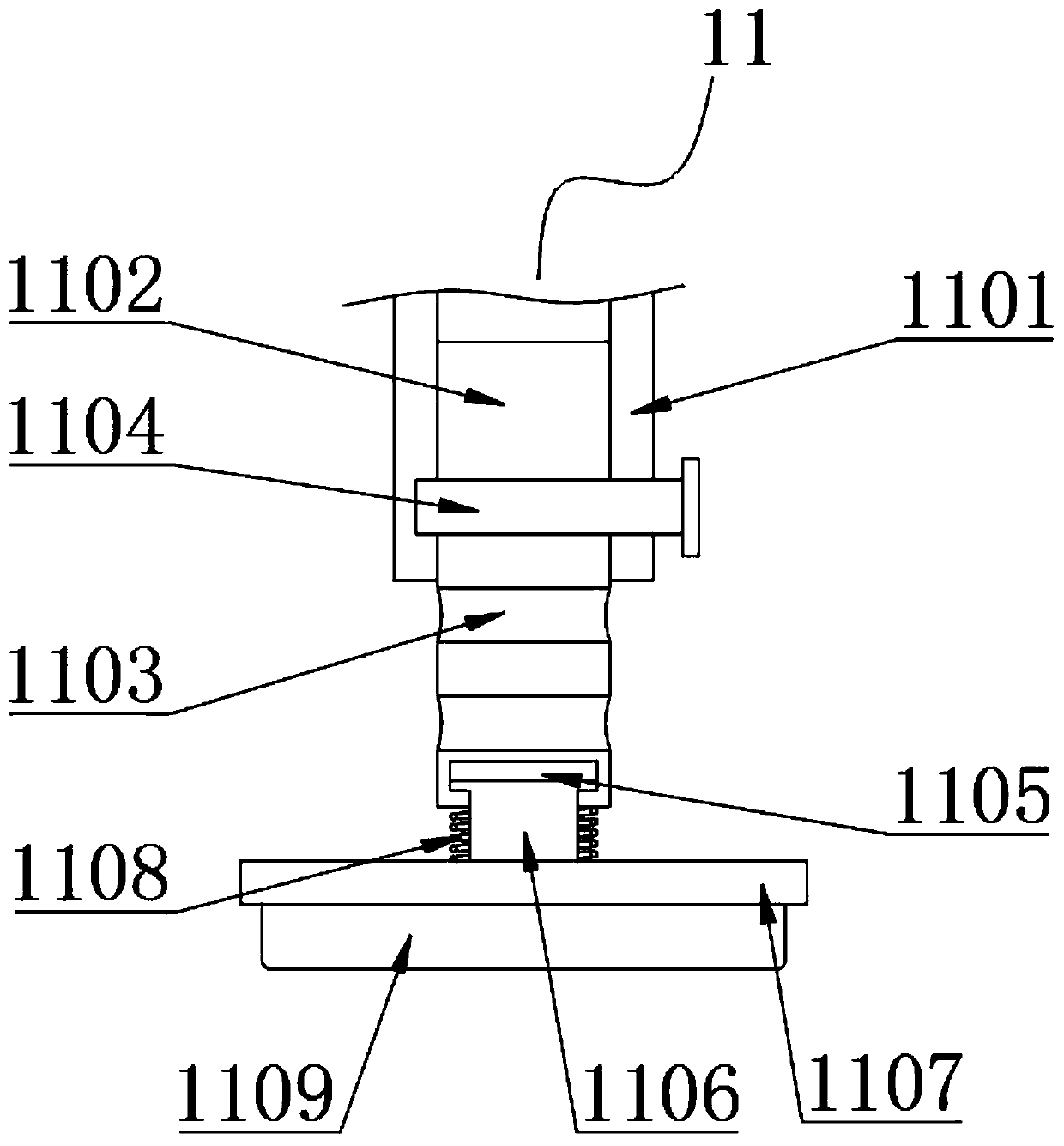

[0041] Example: such as Figure 1-7 As shown, the present invention provides a technical solution, a magnetic particle flaw detection trolley for a wheel axle flaw detector taking into account the axle flaw detection function, including a vehicle body 1, a flaw detection top cover 2 connected to the top end of the vehicle body 1, and a moving wheel 3 connected to the bottom end of the vehicle body 1 One end of the vehicle body 1 is embedded with a side cover 4, and the inner wall of the flaw detection top cover 2 is embedded with a camera 5. The model of the camera 5 is osmo action. A storage bin 7, the inner wall of the storage bin 7 is slidably connected with a storage bucket 8, the top of the vehicle body 1 is provided with a drain 9 corresponding to the position of the storage bin 7, and the bottom of the drain 9 is evenly penetrated with a leak hole 10;

[0042] The input end of the camera 5 is electrically connected to the output end of the mains, the outside of the body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com