Method for controlling electric tool, and electric tool designed for carrying out method

A technology for power tools and processing tools, applied in manufacturing tools, general control systems, automatic control devices, etc., and can solve problems such as cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

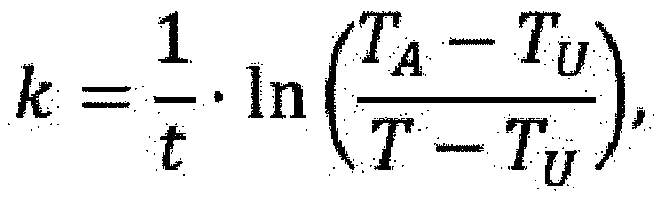

[0036] Newton's law of cooling is written in terms of the differential equation it solves as:

[0037]

[0038] in,

[0039] t: time,

[0040] k: cooling constant,

[0041] T A : at t 0 = the temperature of the object at time 0,

[0042] T U : ambient temperature,

[0043] T: The temperature of the object at time t.

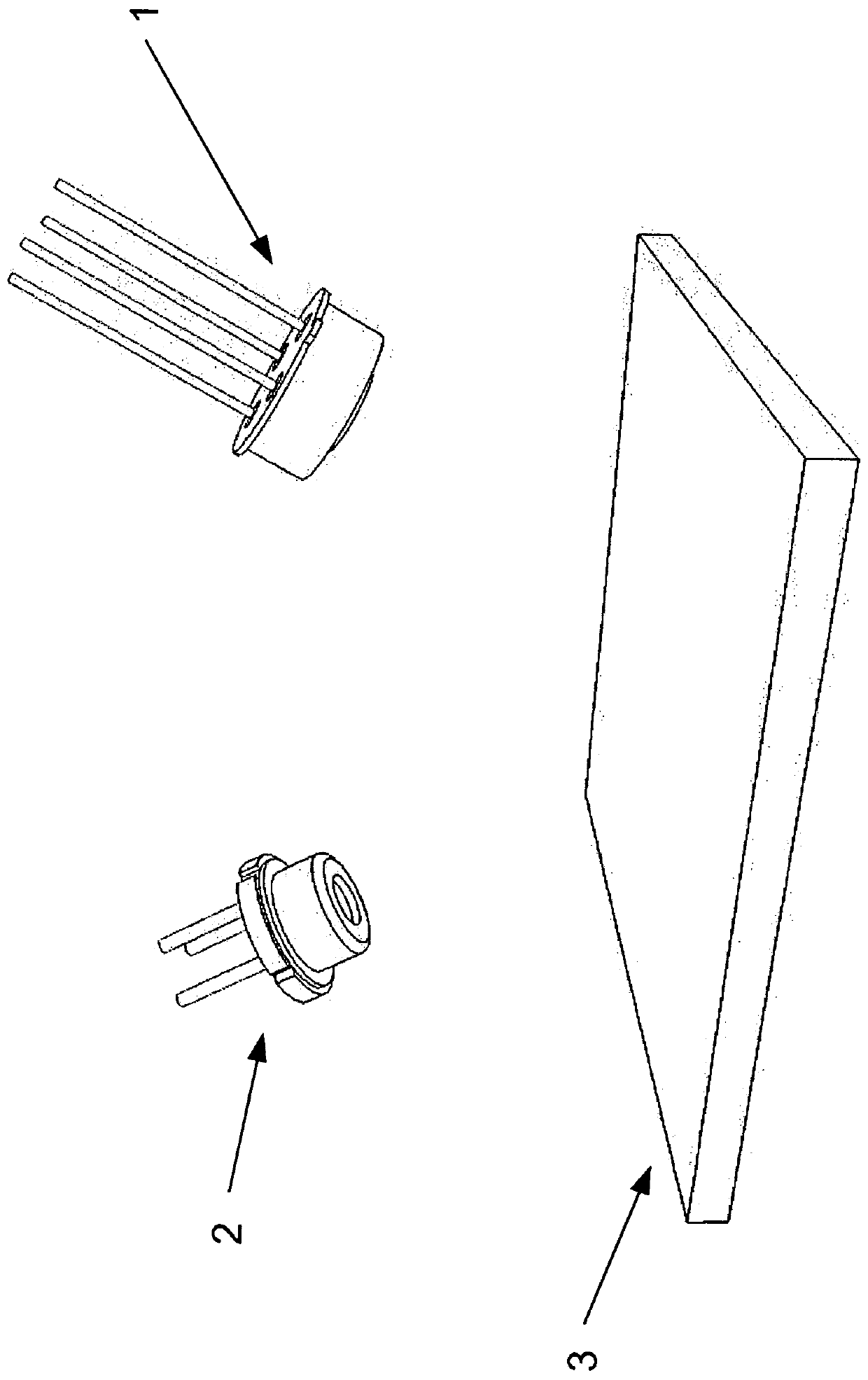

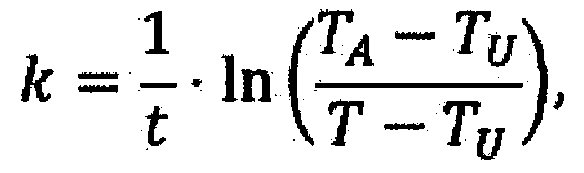

[0044] Within the scope of the present invention, a device or a method is proposed for non-contact determination of the cooling constant of an object or workpiece and thus of the material the workpiece is made of. For this purpose, the ambient temperature is firstly measured by the infrared temperature sensor 1 . For this it is assumed that the sensor temperature itself is equal to the ambient temperature T U . The infrared temperature sensor 1 is capable of determining not only its sensor temperature, but also the temperature of other objects that are not in contact with the sensor. The spot laser beam is now directed via the laser diode 2 at the w...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap