Small Fritillaria thunbergii directional planting machine

A technology of directional planting and fritillaria, which is applied to agricultural machinery and implements, shovels, plows, etc., can solve the problems of complex planting procedures, heavy labor, and large seeders, and achieve low soil breaking and light structure Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the accompanying drawings.

[0016] In order to make the purpose, technical solution and features of the present invention more clear, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific implementation methods. It should be understood that the specific embodiments described here are only used to explain the present invention, and are not intended to limit the present invention.

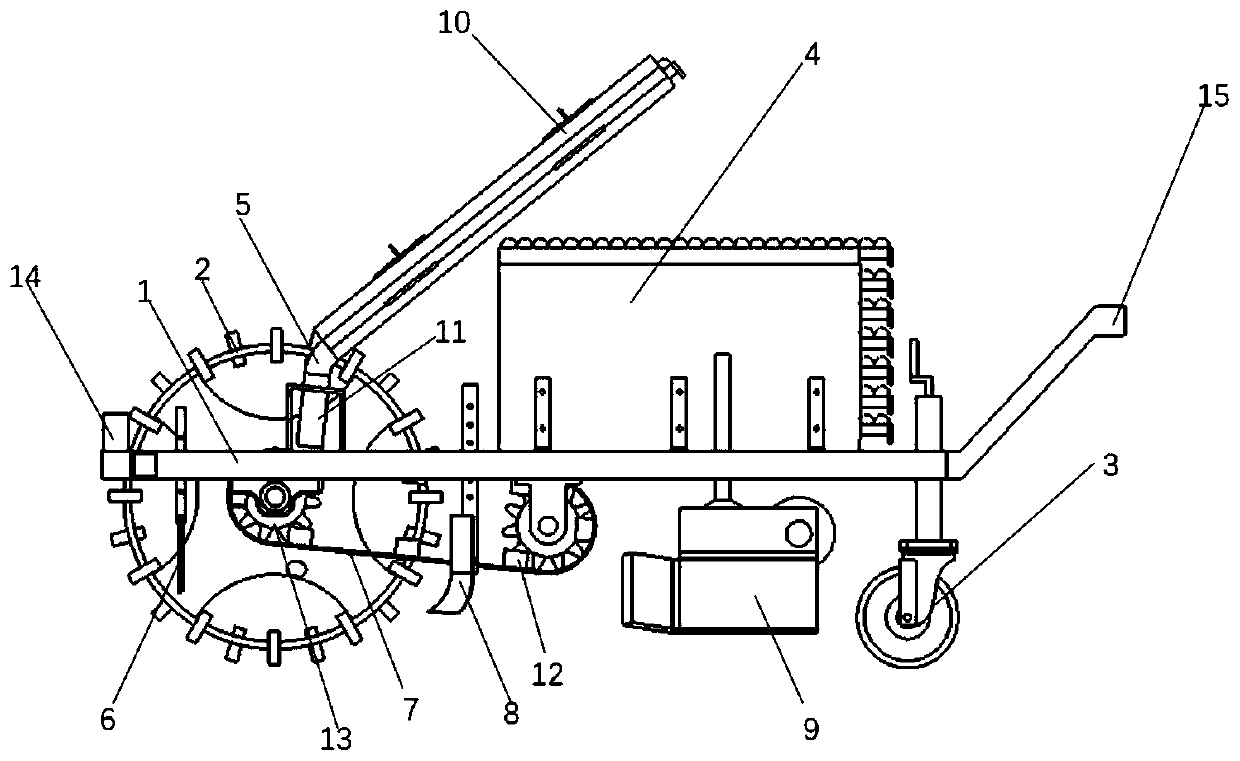

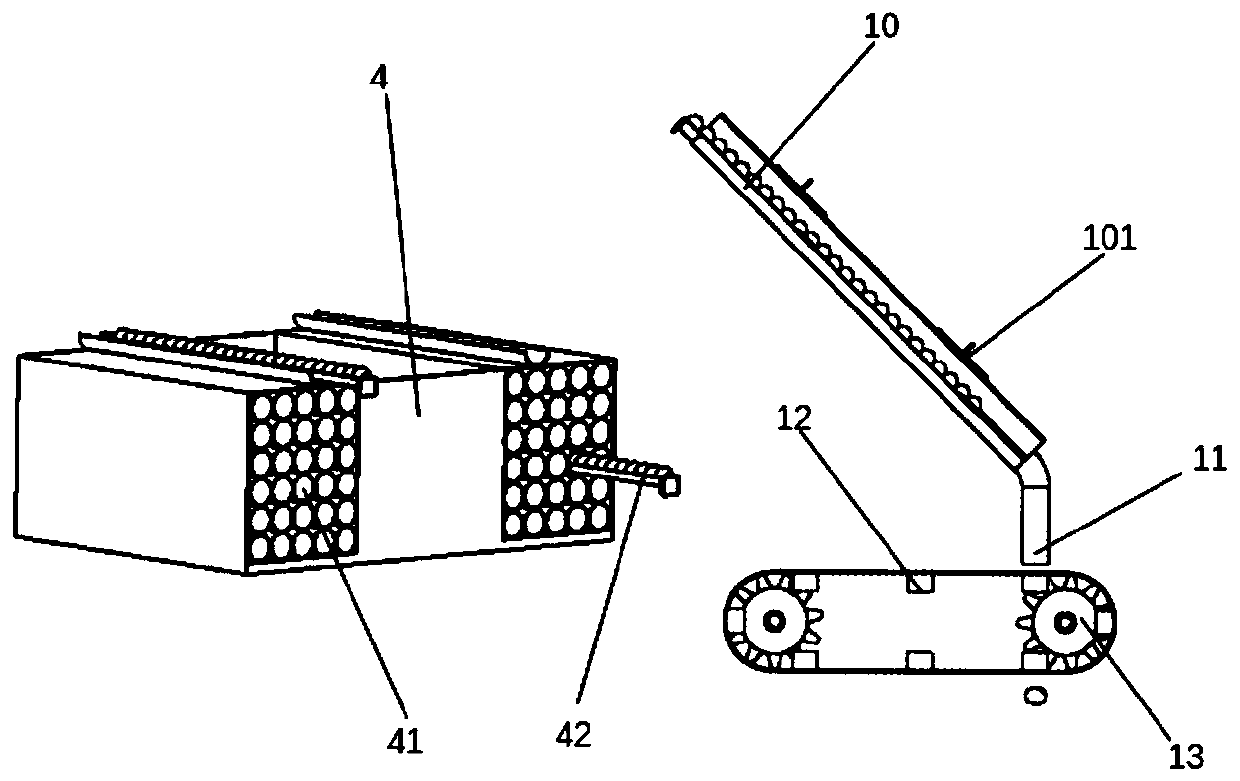

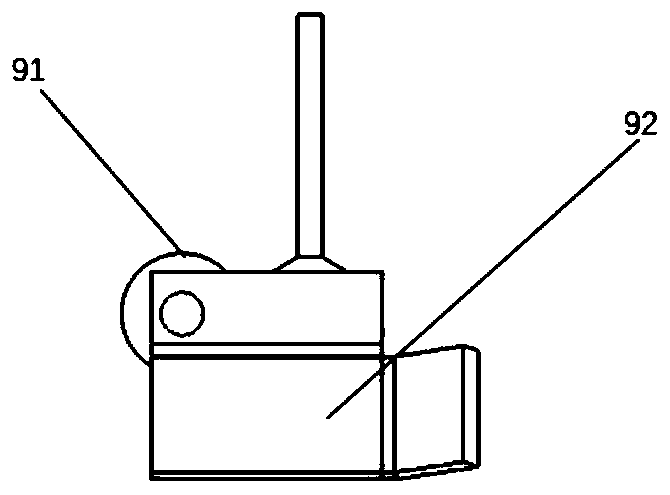

[0017] Such as figure 1 It is a small-sized Fritillaria directional planter of the present invention, comprising a frame 1, a ground wheel 2, a universal wheel 3, a seed box 4, a sowing channel 5, a ditching plow 6, a seed belt 7, a soil shovel 8, Ridging and shaping suppression device 9, open and close feeding pipe 10, feeding pipe 11, seed cup 12, driving wheel 13, hook 14 and handrail 15. Those skilled in the art only need to fixedly connect the h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com