Winch for construction engineering

A construction engineering and hoist technology, applied in the direction of hoisting device, clockwork mechanism, etc., can solve the problems of no anti-fall, extended construction scope, single function, etc., to achieve reasonable design, wide working scope, and increased safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

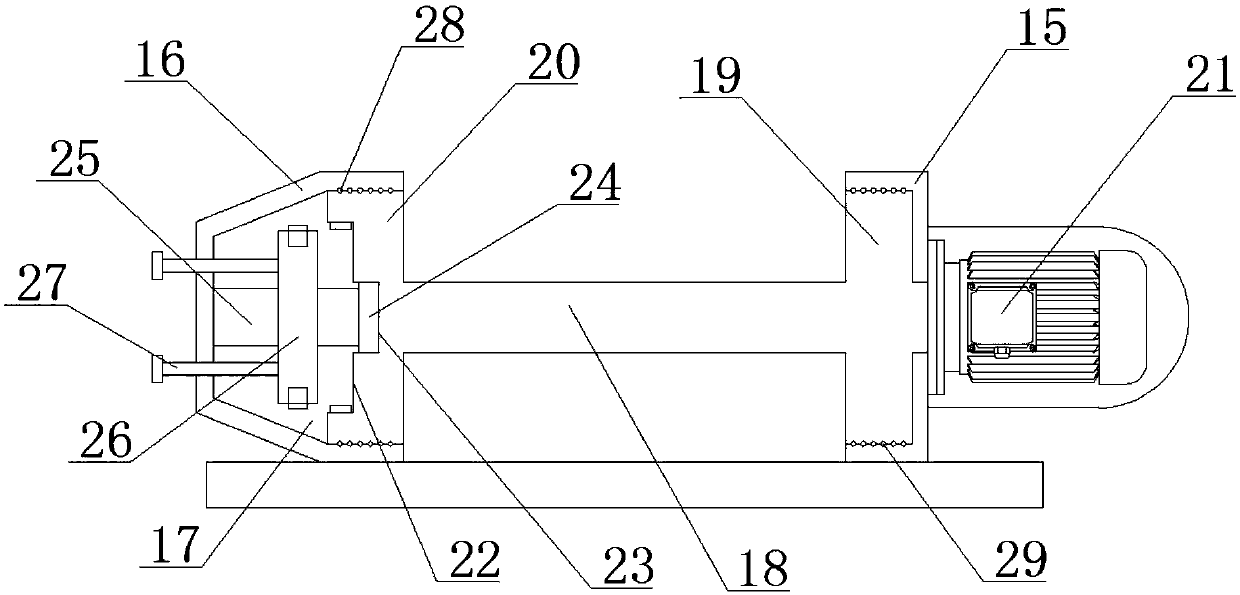

[0022] As a preferred embodiment of the present invention, a steel ball 28 is arranged between the rotating disk 19 and the protective shell 15 .

[0023] As a preferred embodiment of the present invention, a steel ball 29 is arranged between the second rotating disk 20 and the second protective shell 16 .

[0024] As a preferred embodiment of the present invention, the base 1 is provided with screw holes 35, and the number of the screw holes 35 is six.

[0025] As a preferred embodiment of the present invention, the motor 21 is provided with a motor switch.

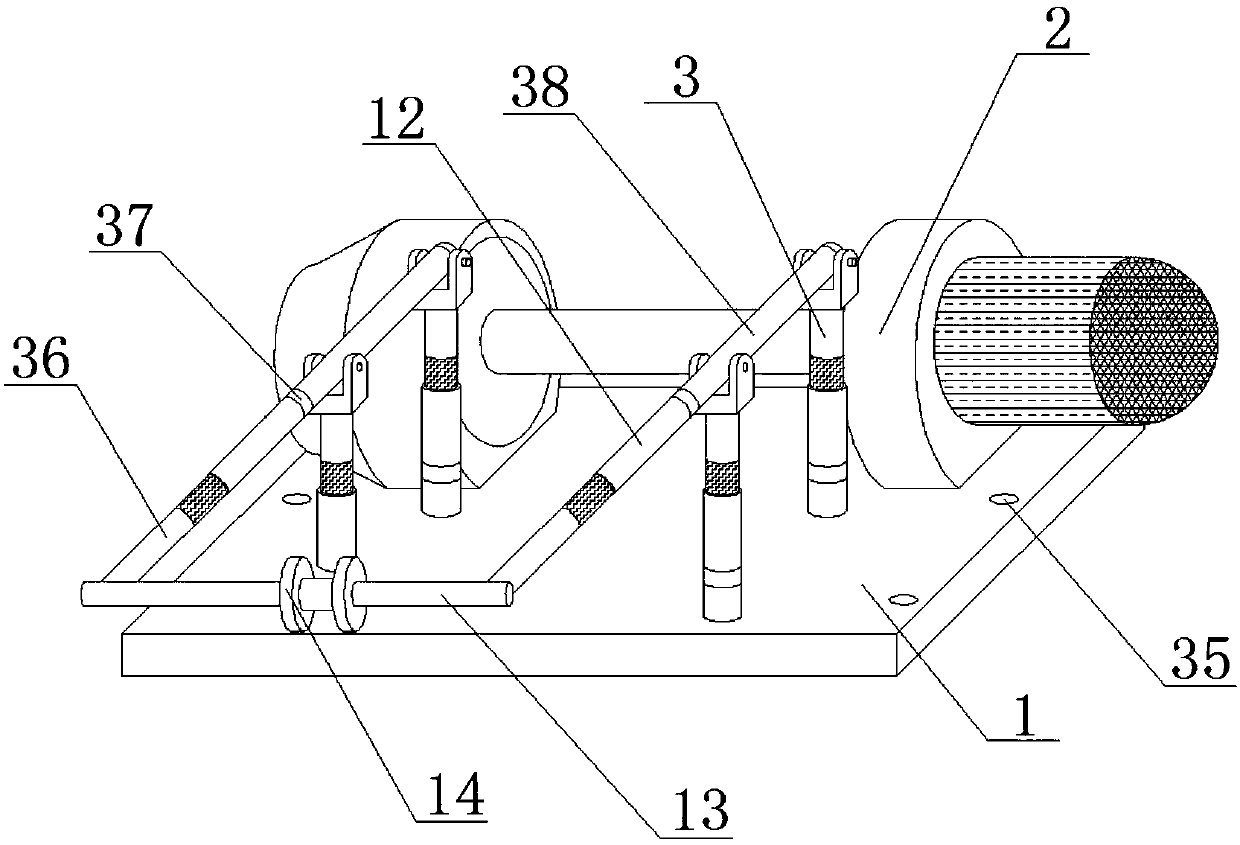

[0026] As a preferred embodiment of the present invention, the number of the support rods 3 is four.

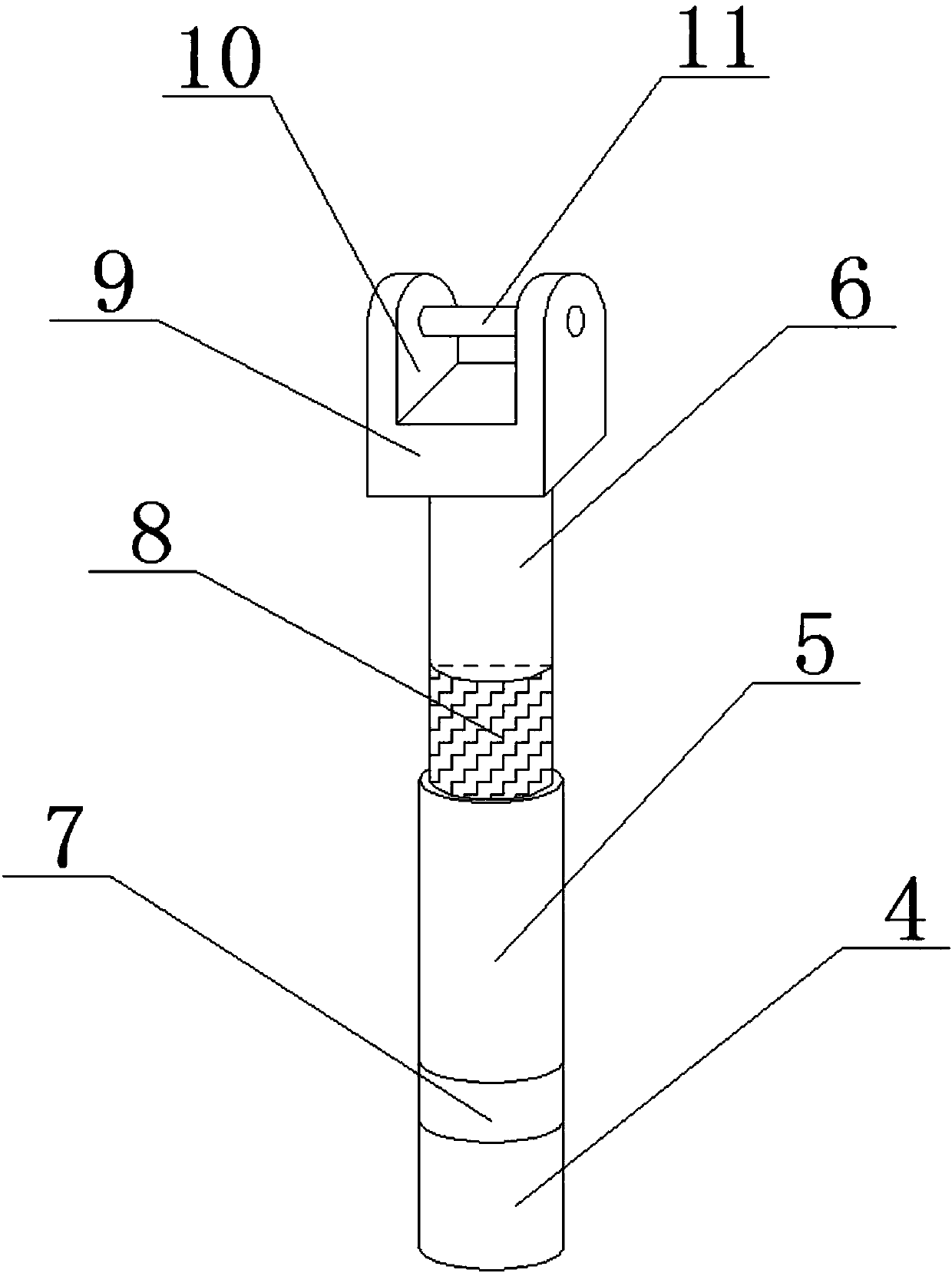

[0027] Working principle: When using the hoist for construction engineering, pass the hoist for construction engineering through

[0028]The screw hole 35 and the screw are fixed in a suitable position, and the steel wire is wound on the rotating rod 18. When in use, one end of the steel wire is passed around the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com