A biomimetic superhydrophobic anti-corrosion and scale-inhibiting coating and preparation method thereof

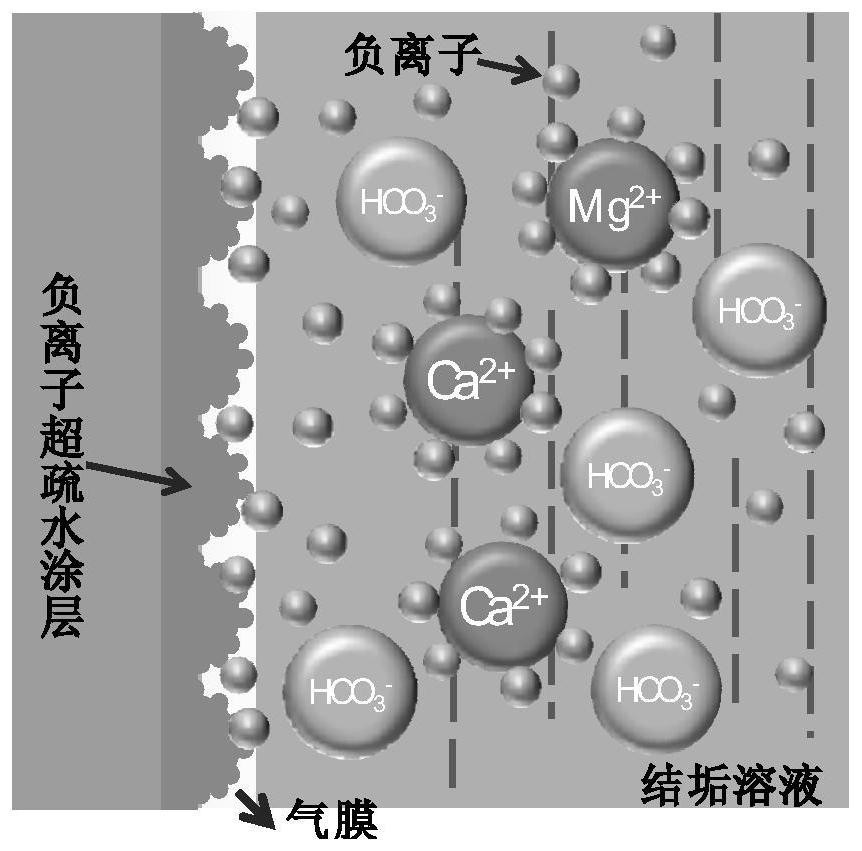

A super-hydrophobic and coating technology, applied in anti-corrosion coatings, coatings, etc., can solve the problems of poor anti-corrosion and scale-inhibition performance, achieve the effect of good corrosion resistance, good scale inhibition performance, and reduce the probability of mutual contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] 1. Preparation of coatings for superhydrophobic anti-corrosion and anti-scale coatings

[0048] Evenly disperse 4 parts of carbon nanofibers, 10 parts of titanium oxide whiskers, 15 parts of negative ion powder, and 2 parts of dopamine hydrochloride in 40 parts of deionized water, stir evenly for 24 hours, filter and dry, and then dry the particles and 2 parts Parts of perfluorosilane, 70 parts of liquid crystal polymer (brand: VECTRA A150), 10 parts of polytetrafluoroethylene, uniformly dispersed in 80 parts of organic solvent.

[0049] 2. Pretreatment of metal substrate surface:

[0050] Use 400-mesh sandpaper to polish the surface of the aluminum substrate to remove the surface oxide film, and then put it into a mixed solution of ethanol and water for ultrasonic cleaning to remove impurities such as grease and dust on the surface. Use a mixed solution of ethanol and water to mix in equal volumes. Take out the aluminum plate and dry it for later use.

[0051] 3. Prepa...

Embodiment 2

[0061] 1. Preparation of coatings for superhydrophobic anti-corrosion and anti-scale coatings

[0062] 10 parts of carbon nanotubes, 10 parts of negative ion powder, 3 parts of dopamine hydrochloride, and 5 parts of hydroxyfluorosilane were uniformly dispersed in 50 parts of deionized water, stirred evenly for 24 hours, filtered and dried, and then the dried particles were mixed with 80 parts Parts of liquid crystal polymer (brand: DuPont 38045), 15 parts of perfluoroethylene propylene copolymer, uniformly dispersed in 90 parts of organic solvent.

[0063] 2. Preparation of superhydrophobic anti-corrosion and anti-scale coating

[0064] The metal substrate is sprayed at a constant temperature of 50°C, and then the coating of this example is placed in a programmed temperature control box and heated at 260°C for 10 minutes, then heated to 280°C for 30 minutes, and then cooled naturally to room temperature.

[0065] 3. Determination of coating properties

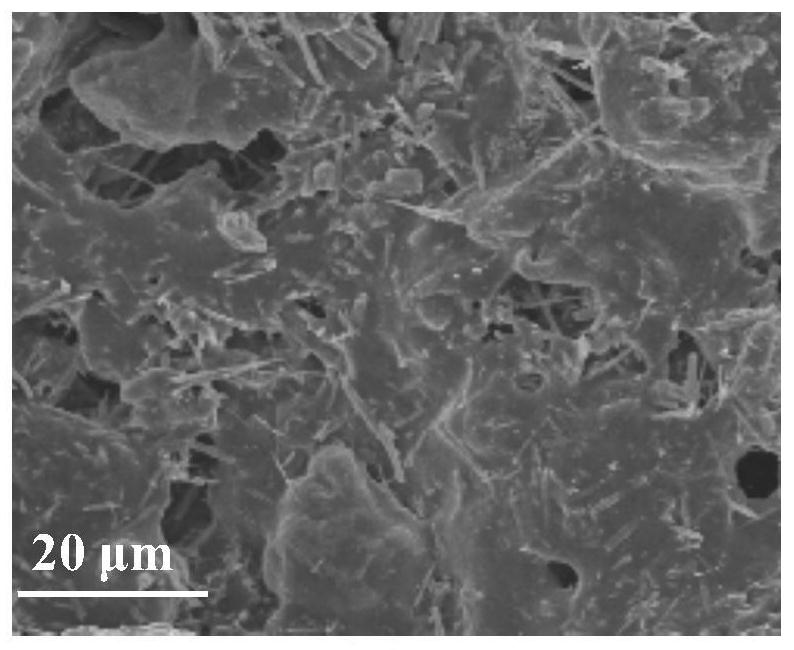

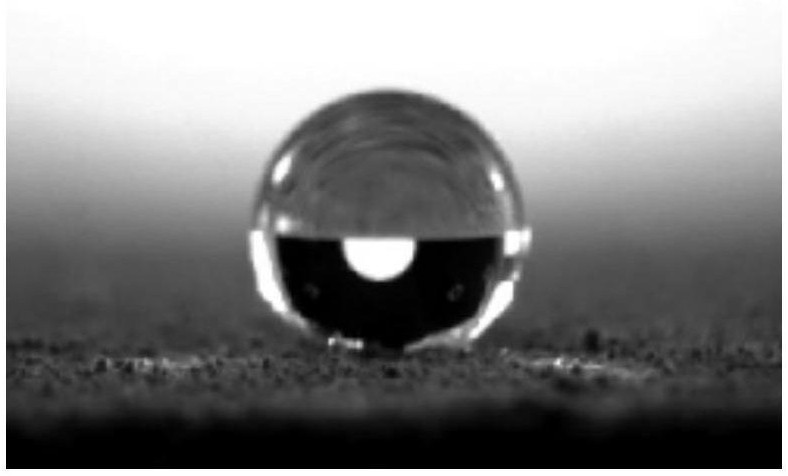

[0066] Hydrophobicity...

Embodiment 3

[0072] 1. The composition and ratio of the coating used for the super-hydrophobic anti-corrosion and anti-scaling coating: 10 parts of titanium oxide whiskers, 2 parts of carbon nanofibers, 10 parts of negative ion powder, 2 parts of dopamine hydrochloride, 4 parts of perfluorooctanoic acid, 40 parts of deionized water, 60 parts of liquid crystal polymer (brand: VECTRA A150), 40 parts of polyvinylidene fluoride, and 100 parts of organic solvent.

[0073] 2. Preparation of superhydrophobic anti-corrosion and anti-scale coating

[0074] The metal substrate is sprayed at a constant temperature of 50°C, and then the coating of this example is placed in a programmed temperature control box and heated at 200°C for 10 minutes, then heated to 260°C for 30 minutes, and then cooled naturally to room temperature.

[0075] 3. Determination of coating properties

[0076] Hydrophobicity: The contact angle between the surface of the coating prepared in this example and a 10 μL deionized wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com