Prestressed fabricated concrete beam-column connection joint and construction method thereof

A beam-column connection and prefabricated concrete technology, which is applied in the direction of construction and building construction, can solve problems such as difficulty in on-site pouring, difficult arrangement of energy-consuming steel bars, and complicated formwork, so as to solve the problem of incomplete arrangement and improve production efficiency and the effect of construction and installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

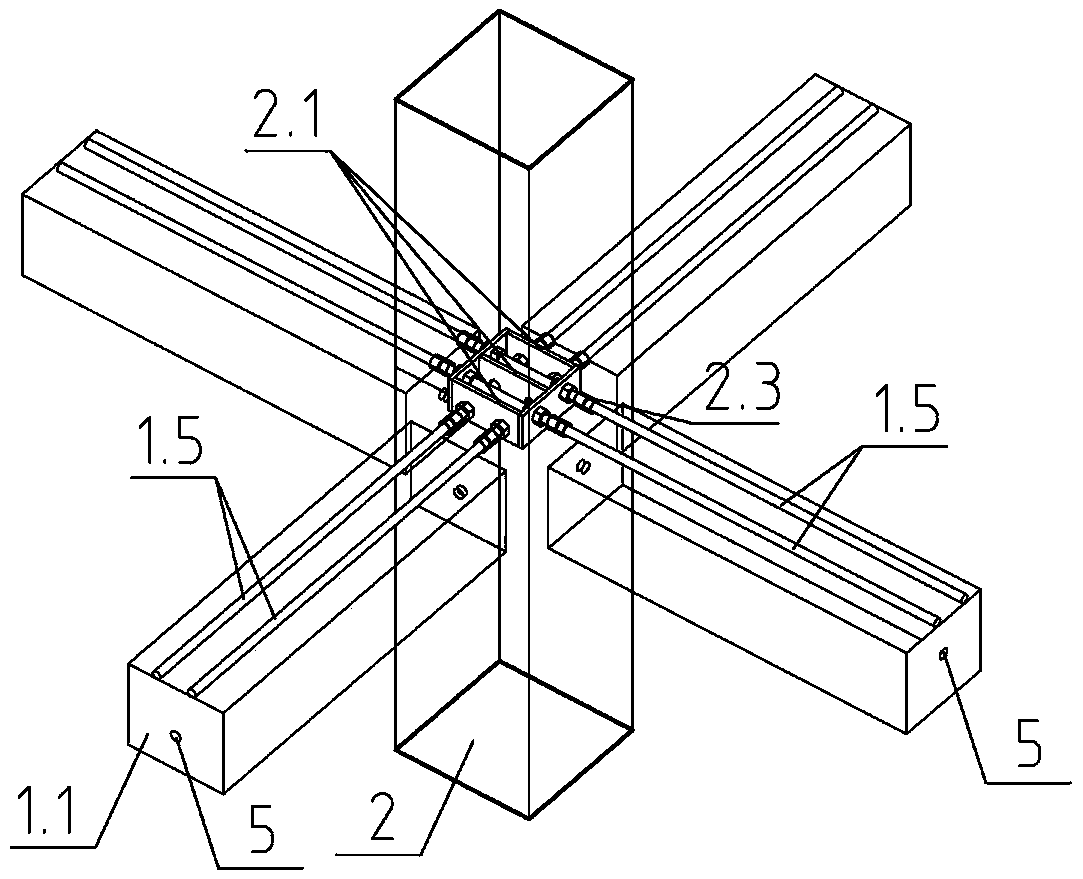

[0069] Such as figure 1 As shown, the present invention provides a prestressed prefabricated concrete beam-column connection node, which is a middle node, including a precast concrete column 2, a first anchor embedded component 2.1 arranged in the precast concrete column 2, and a precast concrete beam 1.1 , the beam post-cast laminated layer 1.2 arranged on the upper part of the precast concrete beam 1.1, the beam top energy-dissipating steel bar 1.5 arranged in the beam post-cast laminated layer 1.2, and the steel bars arranged at the joint between the precast concrete beam 1.1 and the precast concrete column 2 The adhesive layer 6, and the post-tensioned prestressed tendon 3 for connecting the precast concrete column 2 and the precast concrete beam 1.1. The use of post-tensioned prestressed steel tendons 3 makes the structure have a certain self-recovery property under earthquake action.

[0070] Such as figure 2 , 3 As shown, this node is a middle node, and the precast ...

Embodiment 2

[0084] see Figure 14 shown. Embodiment 3, a prestressed prefabricated concrete beam-column connection node and construction method, the same as embodiment 2, the difference is that the connection node is a corner node, and the prefabricated concrete beam 1.1 is L-shaped, including a horizontal prefabricated main beam and a longitudinal prefabricated beam. Main beam.

Embodiment 3

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com